Abstract

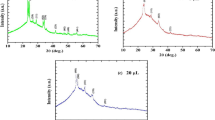

Atmospheric pressure atomic layer deposition (AP-ALD) of iron oxide, as a catalyst for water-assisted chemical vapor deposition (WA-CVD) growth of vertically aligned carbon nanotubes (VA-CNTs), was studied. Fe2O3 film was deposited on the porous Al2O3/SiO2/Si substrate using ferrocene and O2 as precursors. The self-liming film growth was obtained at the temperature window of about 180–250 °C with the optimum dosing and purging duration of about 20 min. The rather longer dosing time here compared to the conventional ALD is attributed to the high pressure as well as high porosity of the substrate. Considering the lower deposition rate at the beginning of the growth, it is suggested that the substrate-inhibited growth mode takes place in this work. The grown films have been characterized by SEM, AFM, Raman, and XRR. Raman spectroscopy peaks were consistent with the formation of Fe2O3. SEM images showed that the uniform coating of Fe2O3 follows the Volmer–Weber growth mode. The catalyst thickness-dependent growth of VACNTs revealed that the deposition through 12 cycles at 250 °C provides sufficient thickness, which resulted in the growth of mm-tall VA-CNTs within a relatively short time of WA-CVD. The changes in the catalyst, i.e. surface roughness and particle size, as a function of WA-CVD time were investigated. The time-dependent evolutions were mainly due to the subsurface diffusion and Ostwald ripening that ultimately led to the growth termination of CNTs.

Graphic abstract

Similar content being viewed by others

References

Futaba DN, Hata K, Yamada T, Hiraoka T, Hayamizu Y, Kakudate Y, Tanaike O, Hatori H, Yumura M, Iijima S (2006) Shape-engineerable and highly densely packed single-walled carbon nanotubes and their application as super-capacitor electrodes. Nat Mater 5:987–994. https://doi.org/10.1038/nmat1782

Jiang H, Lee PS, Li C (2013) 3D carbon based nanostructures for advanced supercapacitors. Energy Environ Sci 6:41–53. https://doi.org/10.1039/c2ee23284g

Zhang H, Cao G, Yang Y (2009) Carbon nanotube arrays and their composites for electrochemical capacitors and lithium-ion batteries. Energy Environ Sci 2:932–943. https://doi.org/10.1039/b906812k

Cheng J, Zhao B, Zhang W, Shi F, Zheng G, Zhang D, Yang J (2015) High-performance supercapacitor applications of NiO-nanoparticle-decorated millimeter-long vertically aligned carbon nanotube arrays via an effective supercritical CO2-assisted method. Adv Funct Mater 25:7381–7391. https://doi.org/10.1002/adfm.201502711

Talapatra S, Kar S, Pal SK, Vajtai R, Ci L, Victor P, Shaijumon MM, Kaur S, Nalamasu O, Ajayan PM (2006) Direct growth of aligned carbon nanotubes on bulk metals. Nat Nanotechnol 1:18–22. https://doi.org/10.1038/nnano.2006.56

Wei C, Dai L, Roy A, Tolle TB (2006) Multifunctional chemical vapor sensors of aligned carbon nanotube and polymer composites. J Am Chem Soc 128:1412–1413

Pushparaj VL, Shaijumon MM, Kumar A, Murugesan S, Ci L, Vajtai R, Linhardt RJ, Nalamasu O, Ajayan PM (2007) Flexible energy storage devices based on nanocomposite paper. Proc Natl Acad Sci USA 104:1–4

Fornasiero F, Gyu H, Holt JK, Stadermann M, Grigoropoulos CP, Noy A, Bakajin O (2008) Ion exclusion by sub-2-nm carbon nanotube pores. Proc Natl Acad Sci 105(45):17250–17255

Holt JK (2006) Fast mass transport through sub-2-nanometer carbon nanotubes. Science. https://doi.org/10.1126/science.1126298

Nednoor P, Gavalas VG, Chopra N, Hinds J, Bachas LG (2007) Carbon nanotube based biomimetic membranes : mimicking protein channels regulated by phosphorylation. J Mater Chem J Mater Chem A. https://doi.org/10.1039/b703365f

Futaba DN, Hata K, Yamada T, Mizuno K, Yumura M, Iijima S (2005) Kinetics of water-assisted single-walled carbon nanotube synthesis revealed by a time-evolution analysis. Phys Rev Lett 056104:1–4. https://doi.org/10.1103/PhysRevLett.95.056104

Hata K, Futaba DN, Mizuno K, Namai T, Yumura M (2010) Water-assisted highly efficient synthesis of impurity-free single-walled carbon nanotubes. Science 306:1362–1364

Zhang H, Cao G, Wang Z, Yang Y, Shi Z, Gu Z (2008) Influence of hydrogen pretreatment condition on the morphology of Fe / Al 2 O 3 catalyst film and growth of millimeter-long carbon nanotube array. J Phys Chem C 112:4524–4530

Di J, Yong Z, Yang X, Li Q (2011) Structural and morphological dependence of carbon nanotube arrays on catalyst aggregation. Appl Surf Sci 258:13–18. https://doi.org/10.1016/j.apsusc.2011.07.130

Wang Y, Luo Z, Li B, Ho PS, Yao Z, Shi L, Bryan EN, Nemanich RJ (2007) Comparison study of catalyst nanoparticle formation and carbon nanotube growth: support effect. J Appl Phys. https://doi.org/10.1063/1.2749412

Amama PB, Pint CL, McJilton L, Kim SM, Stach EA, Murray PT, Hauge RH, Maruyama B (2009) Role of water in super growth of single-walled carbon nanotube carpets. Nano Lett 9:44–49. https://doi.org/10.1021/nl801876h

Yun Y, Shanov V, Tu Y, Subramaniam S, Schulz MJ (2006) Growth mechanism of long aligned multiwall carbon nanotube arrays by water-assisted chemical vapor deposition. J Phys Chem B 110:23920–23925

Pint CL, Pheasant ST, Parra-Vasquez ANG, Horton C, Xu Y, Hauge RH (2009) Investigation of optimal parameters for oxide-assisted growth of vertically aligned single-walled carbon nanotubes. J Phys Chem C 113:4125–4133. https://doi.org/10.1021/jp8070585

Kim SM, Cary LP, Placidus BA, Dmitri NZ, Robert HH, Maruyama B, Stach EA (2010) Evolution in catalyst morphology leads to carbon nanotube growth termination. J Phys Chem Lett 1:918–922. https://doi.org/10.1021/jz9004762

Sengupta J, Jacob ÆC (2010) The effect of Fe and Ni catalysts on the growth of multiwalled carbon nanotubes using chemical vapor deposition. J Nanoparticle Res 12:457–465. https://doi.org/10.1007/s11051-009-9667-1

Li BQ, Zhang X, Depaula RF, Zheng L, Zhao Y, Stan L, Holesinger TG, Arendt PN, Peterson DE, Zhu YT (2006) Sustained growth of ultralong carbon nanotube arrays for fiber spinning **. Adv Mater. https://doi.org/10.1002/adma.200601344

Xiong G-Y, Wang DZ, Ren ZF (2006) Aligned millimeter-long carbon nanotube arrays grown on single crystal magnesia. Carbon N Y 44:969–973. https://doi.org/10.1016/j.carbon.2005.10.015

Yamada T, Namai T, Hata K, Futaba DONN, Mizuno K, Fan J, Yudasaka M, Yumura M, Iijima S (2006) Size-selective growth of double-walled carbon nanotube forests from engineered iron catalysts. Nat Nanotechnol. https://doi.org/10.1038/nnano.2006.95

Christen HM, Puretzky AA, Cui H, Belay K, Fleming PH (2004) Rapid growth of long, vertically aligned carbon nanotubes through efficient catalyst optimization using metal film gradients. Nano Lett 4:1939–1942

Lettiere BR, Chazot CAC, Cui K, John Hart A (2020) High-density carbon nanotube forest growth on copper foil for enhanced thermal and electrochemical interfaces. ACS Appl Nano Mater 3:77–83. https://doi.org/10.1021/acsanm.9b01595

Teblum E, Noked M, Grinblat J, Kremen A, Muallem M, Fleger Y, Tischler YR, Aurbach D, Nessim GD (2014) Millimeter-tall carpets of vertically aligned crystalline carbon nanotubes synthesized on copper substrates for electrical applications. J Phys Chem C 118:19345–19355. https://doi.org/10.1021/jp5015719

Hinds BJ, Chopra N, Rantell T, Andrews R, Gavalas V, Bachas LG (2014) Aligned multiwalled carbon nanotube membranes. Science 62:62–65. https://doi.org/10.1126/science.1092048

Pradhan NR, Duan H, Liang J, Iannacchione GS (2009) The specific heat and effective thermal conductivity of composites containing single-wall and multi-wall carbon nanotubes. Nanotechnology 20:245705. https://doi.org/10.1088/0957-4484/20/24/245705

Li J, Papadopoulos C, Xu JM, Moskovits M, Li J, Papadopoulos C, Xu JM (2013) Highly-ordered carbon nanotube arrays for electronics applications. Appl Phys Lett 367:10–13. https://doi.org/10.1063/1.124377

Matsumoto N, Oshima A, Ishizawa S, Chen G, Hata K, Futaba DN (2018) One millimeter per minute growth rates for single wall carbon nanotube forests enabled by porous metal substrates. RSC Adv 8:7810–7817. https://doi.org/10.1039/c7ra13093g

Matsumoto N, Ishizawa S, Hata K, Futaba DN (2018) High yield single-walled carbon nanotube synthesis through multilayer porous mesh substrates∗. E-J Surf Sci Nanotechnol 16:279–282. https://doi.org/10.1380/ejssnt.2018.279

Kim DY, Sugime H, Hasegawa K, Osawa T, Noda S (2011) Sub-millimeter-long carbon nanotubes repeatedly grown on and separated from ceramic beads in a single fluidized bed reactor. Carbon N Y 49:1972–1979. https://doi.org/10.1016/j.carbon.2011.01.022

Chen Z, Kim DY, Hasegawa K, Osawa T, Noda S (2014) Over 99.6 wt%-pure, sub-millimeter-long carbon nanotubes realized by fluidized-bed with careful control of the catalyst and carbon feeds. Carbon NY 80:339–350. https://doi.org/10.1016/j.carbon.2014.08.072

Xiang R, Luo G, Qian W, Wang Y, Wei F, Li Q (2007) Large area growth of aligned CNT arrays on spheres: towards large scale and continuous production. Chem Vap Depos 13:533–536. https://doi.org/10.1002/cvde.200704249

Zhaoli Gao MMFY, Zhang X, Zhang K (2015) Growth of vertically aligned carbon nanotube arrays on al substrates through controlled diffusion of catalyst. J Phys Chem C 119:15636–15642

Chiang W, Futaba DN, Yumura M, Hata K (2011) Growth control of single-walled, double-walled, and triple-walled carbon nanotube forests by a priori electrical resistance measurement of catalyst films. Carbon N Y 49:4368–4375. https://doi.org/10.1016/j.carbon.2011.06.015

Chen G, Sakurai S, Yumura M, Hata K, Futaba DN (2016) Highly pure, millimeter-tall, sub-2-nanometer diameter single-walled carbon nanotube forests. Carbon N Y 107:433–439. https://doi.org/10.1016/j.carbon.2016.06.024.This

Zhu M, Wachs IE (2015) Iron-based catalysts for the high temperature water-gas shift (ht-wgs ) reaction : a review. ACS Catal 6:722–732. https://doi.org/10.1021/acscatal.5b02594

Lv X, Deng J, Sun X (2016) Cumulative effect of Fe 2 O 3 on TiO 2 nanotubes via atomic layer deposition with enhanced lithium ion storage performance. Appl Surf Sci 369:314–319

Klahr BM, Martinson ABF, Hamann TW (2011) Photoelectrochemical investigation of ultrathin film iron oxide solar cells prepared by atomic layer deposition. Langmuir 109:13685–13692. https://doi.org/10.1021/la103541n

Sivula K, Le Formal F, Grätzel M (2011) Solar water splitting : progress using hematite ( a -Fe 2 O 3) photoelectrodes. Chemsuschem 4:432–449. https://doi.org/10.1002/cssc.201000416

Beermann N, Vayssieres L, Lindquist S, Hagfeldt A, Soc JE, Beermann N, Vayssieres L, Lindquist S, Hagfeldt A (2000) Photoelectrochemical studies of oriented nanorod thin films of hematite photoelectrochemical studies of oriented nanorod thin films of hematite. J Electrochem Soc 147:2456–2461. https://doi.org/10.1149/1.1393553

Zolghadr S, Khojier K, Kimiagar S (2015) Ammonia sensing properties of α -Fe 2 O 3 thin films during post-annealing process. Procedia Mater Sci 11:469–473. https://doi.org/10.1016/j.mspro.2015.11.058

Tamm A, Dimri MC, Kozlova J, Aidla A, Tanel T, Hugo M, Stern R, Kukli K, Uno M (2012) Atomic layer deposition of ferromagnetic iron oxide films on three-dimensional substrates with tin oxide nanoparticles. J Cryst Growth 343:21–27. https://doi.org/10.1016/j.jcrysgro.2011.09.062

Pirota KR, Navas D, Hernández-vélez M (2004) Novel magnetic materials prepared by electrodeposition techniques : arrays of nanowires and multi-layered microwires. J Alloys Compd 369:18–26. https://doi.org/10.1016/j.jallcom.2003.09.040

George SM (2010) Atomic layer deposition : an overview. Chem Rev 110:111–131

Mousa MBM, Oldham CJ, Jur JS, Parsons GN, Mousa MBM, Oldham CJ, Carolina N, Carolina N, Parsons GN (2012) Effect of temperature and gas velocity on growth per cycle during Al 2 O 3 and ZnO atomic layer deposition at atmospheric pressure. J Vacu Acuum Sci Technol A. https://doi.org/10.1116/1.3670961

Beetstra BR, Lafont U, Nijenhuis J, Kelder EM, Van Ommen JR (2009) Atmospheric pressure process for coating particles using atomic layer deposition **. Chem Vap Depos 15:227–233. https://doi.org/10.1002/cvde.200906775

Mameli PP, Schulpen J, Roozeboom WMMEK, Roozeboom F (2017) Effect of reactor pressure on the conformal coating inside porous substrates by atomic layer deposition. J. Vacu Acuum Sci Technol A 10(1116/1):4973350

Mousa MBM, Oldham CJ, Parsons GN (2014) Atmospheric pressure atomic layer deposition of Al 2 O 3 using trimethyl aluminum and ozone. Langmuir 30:3741–3748

Lie AKM, Fjellva˚g H (2005) Growth of Fe 2 O 3 thin films by atomic layer deposition. Thin Solid Films 488:74–81. https://doi.org/10.1016/j.tsf.2005.04.063

Ma˚rten Rooth A, Johansson, Kukli K, Aarik J, Boman M, Ha A (2008) Atomic layer deposition of iron oxide thin films and nanotubes using ferrocene and oxygen as precursors **. Chem. Vap. Depos. 14:67–70. https://doi.org/10.1002/cvde.200706649

Scheffe JR, Francés A, King DM, Liang X, Branch BA, Cavanagh AS, George SM, Weimer AW (2009) Atomic layer deposition of iron ( III ) oxide on zirconia nanoparticles in a fluidized bed reactor using ferrocene and oxygen. Thin Solid Films 517:1874–1879. https://doi.org/10.1016/j.tsf.2008.09.086

Martinson ABF, Devries MJ, Libera JA, Christensen ST, Hupp JT, Pellin MJ, Elam W (2011) Atomic layer deposition of Fe 2 O 3 using ferrocene and ozone. J Phys Chem C 115:4333–4339

Bachmann J, Jing J, Knez M, Barth S, Shen H, Mathur S, Planck M, Physics M, Weinberg A (2007) Ordered iron oxide nanotube arrays of controlled geometry and tunable magnetism by atomic layer deposition. J Am Chem Soc 5:9554–9555

Lim BS, Rahtu A, Gordon ROYG (2003) Atomic layer deposition of transition metals. Nat Mater 2:749–754. https://doi.org/10.1038/nmat1000

Elam W, Pellin J, Proslier T (2013) Low temperature atomic layer deposition of highly photoactive hematite using iron(iii) chloride and water. J Mater Chem Aournal Mater Chem A. https://doi.org/10.1039/c3ta12514a

Selvaraj S, Moon H, Yun J, Kim D (2016) Iron oxide grown by low-temperature atomic layer deposition. Korean J Chem Eng 33:3516–3522. https://doi.org/10.1007/s11814-016-0319-8

Li BX, Fan NC, Fan HJ (2013) A micro-pulse process of atomic layer deposition of iron oxide using ferrocene and ozone precursors and Ti-doping. Chem Vap Depos 19:104–110. https://doi.org/10.1002/cvde.201207030

Puurunen RL (2005) Surface chemistry of atomic layer deposition : a case study for the trimethylaluminum/water process. J Appl Phys. https://doi.org/10.1063/1.1940727

T.E. Society, M. Leskel (2004) Atomic layer deposition of iridium thin films. J Electrochem Soc 151:489–492. https://doi.org/10.1149/1.1761011

Jur JS, Parsons GN (2011) Atomic layer deposition of Al 2 O 3 and ZnO at atmospheric pressure in a flow tube reactor. Appl Mater Interfaces 3:299–308

Gao F, Jiang J, Du L, Liu X, Ding Y (2018) General stable and highly efficient Cu / TiO 2 nanocomposite photocatalyst prepared through atomic layer deposition. Appl Catal A Gen 568:168–175

Mackus AJM, Baker L, Kessels WMM (2012) Catalytic combustion and dehydrogenation reactions during atomic layer deposition of platinum. Chem Mater 24:1752–1761

Aaltonen T, Rahtu A, Ritala M, Leskelä M (2003) Reaction mechanism studies on atomic layer deposition of ruthenium and platinum. Electrochem Solid State Lett 6:133–C133. https://doi.org/10.1149/1.1595312

Park SK, Kanjolia R, Anthis J, Odedra R, Boag N, Wielunski L, Chabal YJ (2010) Atomic layer deposition of Ru/RuO2 thin films studied by in situ infrared spectroscopy. Chem Mater 22:4867–4878. https://doi.org/10.1021/cm903793u

Aaltonen BT, Aløn P, Ritala M, Leskelä M (2003) Ruthenium thin films grown by atomic layer deposition **. Chem Vap Depos 9:45–49

Aaltonen T, Ritala M, Arstila K, Keinonen J, Leskelä M (2004) Atomic layer deposition of ruthenium thin films from Ru(thd)3 and oxygen. Chem Vap Depos 10:215–219. https://doi.org/10.1002/cvde.200306288

Dyagileve M, Mar VP (1979) Reactivity of the first transition row metallocenes in thermal decomposition reaction. J Organomet Chem 175:63–72

Jeong M, Yeon S, Han D, Wook S, Hee I, Lee M, Kyu Y, Dok Y (2016) General High-performing and durable MgO / Ni catalysts via atomic layer deposition for CO 2 reforming of methane ( CRM ). Appl Catal A Gen 515:45–50

Edy R, Huang G, Zhao Y, Guo Y (2017) Influence of reactive surface groups on the deposition of oxides thin film by atomic layer deposition. Surf Coat Technol 329:149–154. https://doi.org/10.1016/j.surfcoat.2017.09.047

Pisana SÃ, Cantoro M, Parvez A, Hofmann S, Ferrari AC, Robertson J (2007) The role of precursor gases on the surface restructuring of catalyst films during carbon nanotube growth. Physica E 37:1–5. https://doi.org/10.1016/j.physe.2006.06.014

Amama PB, Pint CL, Kim SM, Mcjilton KL, Eyink KG, Stach EA, Hauge RH, Maruyama B (2010) Influence of alumina type on the evolution and activity of alumina- supported Fe catalysts in single-walled carbon nanotube carpet growth. ACSNANO 4:895–904

Kaushik P, Eliáš M, Michalička J, Hegemann D, Pytlíček Z, Nečas D, Zajíčková L (2019) Atomic layer deposition of titanium dioxide on multi-walled carbon nanotubes for ammonia gas sensing. Surf Coat Technol 370:235–243

Manuscript A (2014) Plasma enhanced atomic layer deposition of Fe2O3 thin films. J Mater Chem Aournal Mater Chem A 2:10662–10667. https://doi.org/10.1039/x0xx00000x

Shang R, Goulas A, Tang CY, De Frias X, Rietveld LC, Heijman SGJ (2017) Atmospheric pressure atomic layer deposition for tight ceramic nano filtration membranes : synthesis and application in water purification. J Memb Sci 528:163–170

Leick N, Verkuijlen ROF, Lamagna L, Langereis E, Rushworth S, Roozeboom F, Van De Sanden MCM, Kessels WMM (2015) Atomic layer deposition of Ru from CpRu ( CO ) 2 Et using O 2 gas and O 2 plasma atomic layer deposition of Ru from CpRu „ CO 2 Et using O 2 gas and O 2 plasma. J Vacuacuum Sci Technol A. https://doi.org/10.1116/1.3554691

Vuurmant MA, Wachs IE (1992) In situ raman spectroscopy of alumina-supported metal oxide catalysts. J Phys Chem 96:5008–5016

Ming T, Monai M, Dai S, Arroyo-ramirez L, Zhang S, Pan X, Graham GW, Fornasiero P, Gorte RJ (2017) High-surface-area, iron-oxide films prepared by atomic layer deposition on γ-Al2O3. Appl Catal A Gen 534:70–77

ONS Ã, Lazor P (2003) Raman spectroscopic study of magnetite ( FeFe 2 O 4 ): a new assignment for the vibrational spectrum, J Solid State Chem 174: 424–430. https://doi.org/10.1016/S0022-4596(03)00294-9.

Arcos TDL, Garnier MG, Seo JW, Oelhafen P, Thommen V, Mathys D (2004) The Influence of catalyst chemical state and morphology on carbon nanotube growth. J Phys Chem B 108:7728–7734

Teblum E, Gofer Y, Pint CL, Nessim GD (2012) Role of catalyst oxidation state in the growth of vertically aligned carbon nanotubes. J Phys Chem C 116:24522–24528

Ago H, Nakamura K, Uehara N, Tsuji M (2004) Roles of metal-support interaction in growth of single- and double-walled carbon nanotubes studied with diameter-controlled iron particles supported on MgO. J Phys Chem B 108:18908–18915

De Los Arcos T, Garnier MG, Seo JW, Oelhafen P, Thommen V, Mathys D (2004) The influence of catalyst chemical state and morphology on carbon nanotube growth. J Phys Chem B 108:7728–7734. https://doi.org/10.1021/jp049495v

Nessim GD, Hart AJ, Kim JS, Acquaviva D, Oh J, Morgan CD, Seita M, Leib JS, Thompson CV (2008) Tuning of vertically-aligned carbon nanotube diameter and areal density through catalyst pre-treatment. Nano Lett 8:3587–3593

Pint CL, Nicholas N, Pheasant ST, Duque JG, Parra-Vasquez NG, Eres G, Pasquali M, Hauge RH (2008) Temperature and gas pressure effects in vertically aligned carbon nanotube growth from Fe-Mo catalyst. J Phys Chem C 112:14041–14051. https://doi.org/10.1021/jp8025539

Bedewy M, Meshot ER, Guo H, Verploegen EA, Lu W, Hart AJ (2009) Collective mechanism for the evolution and self-termination of vertically aligned carbon nanotube growth. J Phys Chem C 113:20576–20582. https://doi.org/10.1021/jp904152v

Bedewy M, Meshot ER, Reinker MJ, Hart AJ (2011) Population growth dynamics of carbon nanotubes. ACSNANO. 11:8974–8989

Cho W, Schulz M, Shanov V (2014) Growth and characterization of vertically aligned centimeter long CNT arrays. Carbon N Y 2:264–273

Hasegawa K, Noda S (2011) Millimeter-tall single-walled carbon nanotubes rapidly grown with and without water. ACS Nano 5:975–984. https://doi.org/10.1021/nn102380j

Hong NT, Koh KH, Lee S (2008) Fast growth of millimeter-long vertically-aligned carbon nanotubes via hot filament chemical vapor deposition. J Korean Phys Soc 53:3603–3607. https://doi.org/10.3938/jkps.53.3603

Zhong G, Iwasaki T, Robertson J, Kawarada H (2007) Growth kinetics of 0.5 cm vertically aligned single-walled carbon nanotubes. J Phys Chem B 111:1907–1910. https://doi.org/10.1021/jp067776s

Chakrabarti S, Gong K, Dai L (2008) Structural evaluation along the nanotube length for super-long vertically aligned double-walled carbon nanotube arrays. J Phys Chem C 112:8136–8139. https://doi.org/10.1021/jp802059t

Chakrabarti S, Nagasaka T, Yoshikawa Y, Pan L, Nakayama Y (2006) Growth of super long aligned brush-like carbon nanotubes. Jpn J Appl Phys Part Lett 45:10–13. https://doi.org/10.1143/JJAP.45.L720

Li Y, Xu G, Zhang H, Li T, Yao Y, Li Q, Dai Z (2015) Alcohol-assisted rapid growth of vertically aligned carbon nanotube arrays. Carbon N Y 91:45–55. https://doi.org/10.1016/j.carbon.2015.04.035

Nessim GD, Al-obeidi A, Grisaru H, Polsen ES, Oliver CR, Zimrin T, Hart AJ, Aurbach D, Thompson CV (2012) Synthesis of tall carpets of vertically aligned carbon nanotubes by in situ generation of water vapor through preheating of added oxygen. Carbon 50:4002–4009

Cho W, Schulz M (2014) Growth termination mechanism of vertically aligned centimeter long carbon nanotube arrays. Carbon N Y 9:609–620

Jung H, Kim W, Oh I, Lee C, Lansalot-matras C, Lee SJ, Myoung J, Lee H, Kim H (2016) Growth characteristics and electrical properties of SiO 2 thin films prepared using plasma-enhanced atomic layer deposition and chemical vapor deposition with an aminosilane precursor. J Mater Sci 51:5082–5091. https://doi.org/10.1007/s10853-016-9811-0

Dominguez GSD, Borbo´n-Nun˜ez HA, Romo-Herrera JM, Mun˜oz-Mun˜oz F, Reynoso-Soto EA, Tiznado H (2017) Optimal sidewall functionalization for the growth of ultrathin TiO 2 nanotubes via atomic layer deposition. J Mater Sci 53:2005–2015. https://doi.org/10.1007/s10853-017-1632-2

Maigne A, Matsuo Y, Nakamura E, Yumura M, Hata K (2012) Role of subsurface diffusion and ostwald ripening in catalyst formation for single-walled carbon nanotube forest growth. J Am Chem Soc 134:2148–2153

Lee J, Lee H, Park J, Lee D, Lee K, Jo B, Cho K, Min S (2016) Effects of SiO2 sub-supporting layer on the structure of a Al2O3 supporting layer, formation of Fe catalyst particles, and growth of carbon nanotube forests. RSV Adv. https://doi.org/10.1039/c6ra12250g

Patole SP, Yu S, Shin D, Kim H (2010) The effect of barrier layer-mediated catalytic deactivation in vertically aligned carbon nanotube growth. J Phys D Appl Phys 43:1–7. https://doi.org/10.1088/0022-3727/43/9/095304

Meshot ER, Hart AJ, Meshot ER, Hart AJ (2013) Abrupt self-termination of vertically aligned carbon nanotube. Appl Phys Lett 113107:90–93. https://doi.org/10.1063/1.2889497

Stadermann M, Sherlock SP, In J, Fornasiero F, Park HG, Artyukhin AB, Wang Y, De Yoreo JJ, Grigoropoulos CP, Bakajin O, Chernov AA, Noy A (2009) Mechanism and kinetics of growth termination in controlled chemical vapor deposition growth of multiwall carbon nanotube arrays. Nano Lett 9:738–744

Arcos TDL, Oelhafen P, Mathys D (2009) The importance of catalyst oxidation for the growth of carbon nanotubes on Si substrates. Carbon N Y 47:1977–1982. https://doi.org/10.1016/j.carbon.2009.03.049

Search H, Journals C, Contact A, Iopscience M, Address IP (2010) Diameter increase in millimeter-tall vertically aligned single-walled carbon nanotubes during growth. Appl Phys Express 3:3–6. https://doi.org/10.1143/APEX.3.045103

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

All authors declare no conflicts of interest in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Vahdatifar, S., Mortazavi, Y. & Khodadadi, A.A. Atmospheric pressure atomic layer deposition of iron oxide nanolayer on the Al2O3/SiO2/Si substrate for mm-tall vertically aligned CNTs growth. J Mater Sci 55, 13634–13657 (2020). https://doi.org/10.1007/s10853-020-04922-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-020-04922-x