Abstract

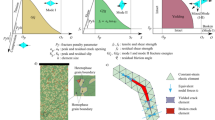

Plant tissue represents cellular material with multiple structural hierarchies enabling a wide range of multifunctionalities and extraordinary mechanical properties. However, it is yet to be elucidated how subcellular-scale mechanical properties and cell-to-cell interactions by a middle lamella (ML) layer are translated to larger scale responses. In this study, we examined an onion epidermal cell wall profile as a representative multicellular material system and developed a novel framework for a multiscale finite element analysis (FEA) model that allows two-scale coupling in a commercial FEA package. The core of this multiscale approach is a 3D repetitive volume element (RVE), which is composed of four cell wall fragments from four adjacent cells attached by a distinct ML layer. We parameterized ML mechanical properties and cell shape anisotropy at RVE to investigate resulting mechanical responses, which were then scaled up to the tissue level. It was observed that, within the elastic limit, the RVE- and tissue-scale mechanical responses are barely affected by ML modulus value; however, they are moderately affected by cell shape factor. The detailed 3D feature of ML interface was found critical for creating anisotropic mechanical behavior and localized stress concentration at RVE scale. Based on the observed results, a soft nanoscopic ML layer with its specified 3D architecture was suggested as the key mediator for attributing multifunctionality in plant cellular material system. The reported computational model framework offers new insight into how different length scales may affect the material properties of multicellular materials exhibiting hierarchical multiscale structures.

Similar content being viewed by others

References

Gibson LJ (2012) The hierarchical structure and mechanics of plant materials. J R Soc Interface 9:2749–2766. doi:10.1098/rsif.2012.0341

Di Giacomo R, Daraio C, Maresca B (2015) Plant nanobionic materials with a giant temperature response mediated by pectin-Ca2+. Proc Natl Acad Sci 112:4541–4545. doi:10.1073/pnas.1421020112

Kerstens S, Decraemer WF, Verbelen J-P (2001) Cell walls at the plant surface behave mechanically like fiber-reinforced composite materials. Plant Physiol 127:381–385

Cosgrove D (1997) Assembly and enlargement of the primary cell wall in plants. Annu Rev Cell Dev Biol 13:171–201

Fujino T, Sone Y, Mitsuishi Y, Itoh T (2000) Characterization of cross-links between cellulose microfibrils, and their occurrence during elongation growth in pea epicotyl. Plant Cell Physiol 41:486–494

Dick-Pérez M, Zhang Y, Hayes J et al (2011) Structure and interactions of plant cell-wall polysaccharides by two- and three-dimensional magic-angle-spinning solid-state NMR. Biochemistry 50:989–1000. doi:10.1021/bi101795q

Anderson CT, Carroll A, Akhmetova L, Somerville C (2010) Real-time imaging of cellulose reorientation during cell wall expansion in arabidopsis roots. Plant Physiol 152:787–796

Rose JKC, Lee S-J (2010) Straying off the highway: trafficking of secreted plant proteins and complexity in the plant cell wall proteome. Plant Physiol 153:433–436. doi:10.1104/pp.110.154872

Wang T, Zabotina O, Hong M (2012) Pectin-cellulose interactions in the arabidopsis primary cell wall from two-dimensional magic-angle-spinning solid-state nuclear magnetic resonance. Biochemistry 51:9846–9856. doi:10.1021/bi3015532

Caffall KH, Mohnen D (2009) The structure, function, and biosynthesis of plant cell wall pectic polysaccharides. Carbohydr Res 344:1879–1900. doi:10.1016/j.carres.2009.05.021

Keegstra K, Albersheim P, Darvill A et al (2010) Plant Cell Walls. Plant Physiol 154:483–486. doi:10.1104/pp.110.161240

Park YB, Cosgrove DJ (2012) Changes in cell wall biomechanical properties in the xyloglucan-deficient xxt1/xxt2 mutant of arabidopsis. Plant Physiol 158:465–475. doi:10.1104/pp.111.189779

Zamil S, Geitmann A (2017) The middle lamella—more than a glue. Phys Biol. doi:10.1088/1478-3975/aa5ba5

Zdunek A, Umeda M (2005) Influence of cell size and cell wall volume fraction on failure properties of potato and carrot tissue. J Texture Stud 36:25–43

Pieczywek PM, Zdunek A (2014) Finite element modelling of the mechanical behaviour of onion epidermis with incorporation of nonlinear properties of cell walls and real tissue geometry. J Food Eng 123:50–59. doi:10.1016/j.jfoodeng.2013.09.012

Konstankiewicz K, Pawlak K, Zdunek A (2001) Influence of structural parameters of potato tuber cells on their mechanical properties. Int Agrophys 15:243–246

Waldron KW, Brett CT (2007) The role of polymer cross-linking in intercellular adhesion. In: Roberts JA, Gonzalez-Carranza Z (eds) Plant cell separation and adhesion. Blackwell Publishing Ltd, Ames, pp 183–204

Faisal T, Rey A, Pasini D (2013) A multiscale mechanical model for plant tissue stiffness. Polymers (Basel) 5:730–750. doi:10.3390/polym5020730

Faisal TR, Hristozov N, Western TL et al (2014) Computational study of the elastic properties of Rheum rhabarbarum tissues via surrogate models of tissue geometry. J Struct Biol 185:285–294. doi:10.1016/j.jsb.2014.01.012

Zhang T, Mahgsoudy-Louyeh S, Tittmann B, Cosgrove D (2014) Visualization of the nanoscale pattern of recently-deposited cellulose microfibrils and matrix materials in never-dried primary walls of the onion epidermis. Cellulose 21:853–862. doi:10.1007/s10570-013-9996-1

Cybulska J, Konstankiewicz K, Zdunek A, Skrzypiec K (2010) Nanostructure of natural and model cell wall material. Int Agrophys 24:107–114

Zdunek A, Pieczywek PM (2013) Study on model development of plant tissue using the finite element method. In: Study model development plant tissue using finite element method. Inside food symposium, Leuven, Belgium, pp 9–12

Vanstreels E, Alamar MC, Verlinden BE et al (2005) Micromechanical behaviour of onion epidermal tissue. Postharvest Biol Technol 37:163–173

Ho QT, Verboven P, Verlinden BE et al (2011) A three-dimensional multiscale model for gas exchange in fruit. Plant Physiol 155:1158–1168. doi:10.1104/pp.110.169391

Ho QT, Carmeliet J, Datta AK et al (2013) Multiscale modeling in food engineering. J Food Eng 114:279–291. doi:10.1016/j.jfoodeng.2012.08.019

Verboven P, Kerckhofs G, Mebatsion HK et al (2008) Three-dimensional gas exchange pathways in pome fruit characterized by synchrotron X-ray computed tomography. Plant Physiol 147:518–527. doi:10.1104/pp.108.118935

Rafsanjani A, Lanvermann C, Niemz P et al (2013) Multiscale analysis of free swelling of Norway spruce. Compos Part A Appl Sci Manuf 54:70–78. doi:10.1016/j.compositesa.2013.07.005

Ghysels P, Samaey G, Tijskens B, Van Liedekerke P, Ramon H, Roose D (2009) Multi-scale simulation of plant tissue deformation using a model for individual cell mechanics. Phys Biol 6:1–14. doi:10.1088/1478-3975/6/1/016009

Mishnaevsky L, Qing H (2008) Micromechanical modelling of mechanical behaviour and strength of wood: state-of-the-art review. Comput Mater Sci 44:363–370. doi:10.1016/j.commatsci.2008.03.043

Loodts J, Tijskens E, Wei C et al (2006) Micromechanics: simulating the elastic behavior of onion epidermis tissue. J Texture Stud 37:16–34. doi:10.1111/j.1745-4603.2006.00036.x

Van Liedekerke P, Ghysels P, Tijskens E et al (2010) Particle-based model to simulate the micromechanics of biological cells and aggregates. Phys Rev E 81:1–13. doi:10.1088/1478-3975/7/2/026006

Smith AE, Moxham KE, Middelberg APJ (1998) On uniquely determining cell–wall material properties with the compression experiment. Chem Eng Sci 53:3913–3922. doi:10.1016/S0009-2509(98)00198-5

Qing H, Mishnaevsky L (2010) 3D multiscale micromechanical model of wood: from annual rings to microfibrils. Int J Solids Struct 47:1253–1267. doi:10.1016/j.ijsolstr.2010.01.014

Pitt RE, Davis DC (1984) Finite element analysis of fluid-filled cell response to external loading. Trans ASAE 27:1976–1983

Bruce DM (2003) Mathematical modelling of the cellular mechanics of plants. Philos Trans R Soc Lond B Biol Sci 358:1437–1444

Wu N, Pitts MJ (1999) Development and validation of a finite element model of an apple fruit cell. Postharvest Biol Technol 16:1–8. doi:10.1016/S0925-5214(98)00095-7

Dintwa E, Jancsók P, Mebatsion HK et al (2011) A finite element model for mechanical deformation of single tomato suspension cells. J Food Eng 103:265–272. doi:10.1016/j.jfoodeng.2010.10.023

Wang CX, Wang L, Thomas CR (2004) Modelling the mechanical properties of single suspension-cultured tomato cells. Ann Bot 93:443–453

Geitmann A (2006) Experimental approaches used to quantify physical parameters at cellular and subcellular levels. Am J Bot 93:1380–1390. doi:10.3732/ajb.93.10.1380

Kim K, Yi H, Zamil MS et al (2015) Multiscale stress–strain characterization of onion outer epidermal tissue in wet and dry states. Am J Bot 102:1–9. doi:10.3732/ajb.1400273

Gao Q, Pitt RE (1990) Mechanics of parenchyma tissue based on cell orientation and microstructure. ASAE 34:232–238

Zamil MS, Yi H, Puri VM (2014) Mechanical characterization of outer epidermal middle lamella of onion under tensile loading. Am J Bot 101:778–787. doi:10.3732/ajb.1300416

Toole GGA, Gunning PA, Parker MML et al (2001) Fracture mechanics of the cell wall of Chara corallina. Planta 212:606–611. doi:10.1007/s004250000425

Clair B, Arinero R, Leveque G et al (2003) Imaging the mechanical properties of wood cell wall layers by atomic force modulation microscopy. IAWA J 24:223–230

Zamil MS, Yi H, Haque A, Virendra MP (2013) Characterizing microscale biological samples under tensile loading: stress-strain behavior of cell wall fragment of onion outer epidermis. Am J Bot 100:1105–1115

Zamil MS, Yi H, Puri V (2015) The mechanical properties of plant cell walls soft material at the subcellular scale: the implications of water and of the intercellular boundaries. J Mater Sci 50:6608–6623. doi:10.1007/s10853-015-9204-9

Kanouté P, Boso DP, Chaboche JL, Schrefler BA (2009) Multiscale methods for composites: a review. Arch Comput Methods Eng 16:31–75. doi:10.1007/s11831-008-9028-8

Kafle K, Xi X, Lee CM et al (2014) Cellulose microfibril orientation in onion (Allium cepa L.) epidermis studied by atomic force microscopy (AFM) and vibrational sum frequency generation (SFG) spectroscopy. Cellulose 21:1075–1086. doi:10.1007/s10570-013-0121-2

Gibson LJ (2005) Biomechanics of cellular solids. J Biomech 38:377–399. doi:10.1016/j.jbiomech.2004.09.027

Greaves GN, Greer AL, Lakes RS, Rouxel T (2011) Poisson’s ratio and modern materials. Nat Mater 10:823–837

Lee J-H, Lee S-S, Chang J-D et al (2013) A novel method for the accurate evaluation of Poisson’s ratio of soft polymeric materials. Sci World J 2013:1–7. doi:10.1155/2013/930798

Snegireva AV, Ageeva MV, Amenitskii SI et al (2010) Intrusive growth of sclerenchyma fibers. Russ J Plant Physiol 57:342–355. doi:10.1134/S1021443710030052

Jarvis MC, Briggs SPH, Knox JP (2003) Intercellular adhesion and cell separation in plants. Plant Cell Environ 26:977–989

Blumer JM, Clay RP, Bergmann CW et al (2000) Characterization of changes in pectin methylesterase expression and pectin esterification during tomato fruit ripening. Can J Bot 78:607–618. doi:10.1139/b00-035

Onoda Y, Schieving F, Anten NPR (2015) A novel method of measuring leaf epidermis and mesophyll stiffness shows the ubiquitous nature of the sandwich structure of leaf laminas in broad-leaved angiosperm species. J Exp Bot 66:2487–2499

Gibson LJ, Ashby MF, Easterling KE (1988) Structure and mechanics of the iris leaf. J Mater Sci 23:3041–3048. doi:10.1007/BF00551271

Geitmann A, Ortega JKE (2009) Mechanics and modeling of plant cell growth. Trends Plant Sci 14:467–478

Monshausen GB, Gilroy S (2009) Feeling green: mechanosensing in plants. Trends Cell Biol 19:228–235. doi:10.1016/j.tcb.2009.02.005

Aragona M, Panciera T, Manfrin A et al (2016) A mechanical checkpoint controls multicellular growth through YAP/TAZ regulation by actin-processing factors. Cell 154:1047–1059. doi:10.1016/j.cell.2013.07.042

Lintilhac PM, Vesecky TB (1984) Stress-induced alignment of division plane in plant tissues grown in vitro. Nature 307:363–364

Nylander M, Svensson J, Palva ET, Welin BV (2001) Stress-induced accumulation and tissue-specific localization of dehydrins in Arabidopsis thaliana. Plant Mol Biol 45:263–279

Jarvis MC (1998) Intercellular separation forces generated by intracellular pressure. Plant, Cell Environ 21:1307–1310

Parker CC, Parker ML, Smith AC, Waldron KW (2001) Pectin distribution at the surface of potato parenchyma cells in relation to cell–cell adhesion. J Agric Food Chem 49:4364–4371. doi:10.1021/jf0104228

Willats WGT, Orfila C, Limberg G et al (2001) Modulation of the degree and pattern of methyl-esterification of pectic homogalacturonan in plant cell walls: implications for pectin methyl esterase action, matrix properties, and cell adhesion. J Biol Chem 276:19404–19413. doi:10.1074/jbc.M011242200

Willats WG, Gilmartin PM, Mikkelsen JD, Knox JP (1999) Cell wall antibodies without immunization: generation and use of de-esterified homogalacturonan block-specific antibodies from a naive phage display library. Plant J 18:57–65

Guillemin F, Guillon F, Bonnin E et al (2005) Distribution of pectic epitopes in cell walls of the sugar beet root. Planta 222:355–371. doi:10.1007/s00425-005-1535-3

Lee KJD, Cornuault V, Manfield IW et al (2013) Multi-scale spatial heterogeneity of pectic rhamnogalacturonan I (RG–I) structural features in tobacco seed endosperm cell walls. Plant J 75:1018–1027. doi:10.1111/tpj.12263

Baskin TI (2005) Anisotropic expansion of the plant cell wall. Annu Rev Cell Dev Biol 21:203–222. doi:10.1146/annurev.cellbio.20.082503.103053

Routier-Kierzkowska A-L, Weber A, Kochova P et al (2012) Cellular force microscopy for in vivo measurements of plant tissue mechanics. Plant Physiol 158:1514–1522. doi:10.1104/pp.111.191460

Beauzamy L, Derr J, Boudaoud A (2015) Quantifying hydrostatic pressure in plant cells by using indentation with an atomic force microscope. Biophys J 108:2448–2456. doi:10.1016/j.bpj.2015.03.035

Acknowledgements

This study was funded by the Center for Lignocellulose Structure and Formation, an Energy Frontier Research Center funded by the U. S. Department of Energy, Office of Science, Office of Basic Energy Sciences under Award Number DE-SC0001090.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Shafayet Zamil, M., Yi, H. & Puri, V.M. A multiscale FEA framework for bridging cell-wall to tissue-scale mechanical properties: the contributions of middle lamella interface and cell shape. J Mater Sci 52, 7947–7968 (2017). https://doi.org/10.1007/s10853-017-0999-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-017-0999-4