Abstract

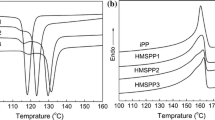

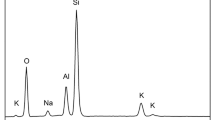

In this work, the reinforcing mechanism of β-form hybrid shish-kebabs induced by β-form nucleating agent (NA) on polypropylene (PP) tapes was revealed. The results showed a hierarchical orientation of fibrous crystalline profile and well-organized β-form PP lamellae existing in the β-form hybrid shish-kebabs, which exhibited remarkable reinforcing effect on the PP tapes in the orientated direction where the tensile strength increased from 44 to 54.7 MPa compared with isotropic one. However, when the tapes were strained perpendicular to the initial orientation, the tensile strength of NA-modified PP tapes decreased to 32.1 MPa. Theoretical analysis was conducted, and a new model was established to interpret this phenomenon. We suggest that specific layer structure constructed by well-organized lamellae and the tie molecules within the β-form hybrid shish-kebabs be responsible for the reinforcing effect due to the promoted fibrillation which stabilizes the crazing zone.

Similar content being viewed by others

References

Liu W, Nie M, Wang Q (2014) Polybutene-1 tube with in situ microfibering polystyrene via helical convergent flow: an economical pathway to continuously fabricate biaxially reinforced polyolefin tubes for medical application. RSC Adv 4:47793–47796

Moore EP (1996) Polypropylene handbook: polymerization, characterization, properties, processing, applications. Hanser-Gardner, Cincinnati

Fujiyama M (1995) Higher order structure of injection-molded polypropylene. In: Karger-kocsis J (ed) Polypropylene: structure, blends and composites. Chapmann & Hall, London, pp 167–204

Kalay G, Bevis MJ (1999) Application of shear-controlled orientation in injection molding of isotactic polypropylene. In: Polypropylene: an AZ reference, vol 2. Kluwer, Dordrecht, p 38

Pantani R, Coccorullo I, Speranza V, Titomanlio G (2005) Modeling of morphology evolution in the injection molding process of thermoplastic polymers. Prog Polym Sci 30:1185–1222

Malkapuram R, Kumar V, Negi YS (2009) Recent development in natural fiber reinforced polypropylene composites. J Reinf Plast Compos 28:1169–1189

Abdou JP, Braggin GA, Luo Y, Stevenson AR, Chun D, Zhang S (2015) Graphene-induced oriented interfacial microstructures in single fiber polymer composites. ACS Appl Mater Int 7:13620–13626

Százdi L, Pukánszky B, Vancso GJ (2006) Quantitative estimation of the reinforcing effect of layered silicates in PP nanocomposites. Polymer 47:4638–4648

Varga J, Tóth FS (1991) Filled compounds of the β-modification of polypropylene. Die Angewandte Makromolekulare Chemie 188:11–25

Dasari A, Yu ZZ, Mai YW (2016) Polymer nanocomposites: towards multi-functionality. Springer, London

Gao CC, Yu L, Liu HS, Chen L (2012) Development of self-reinforced polymer composites. Prog Polym Sci 37:767–780

Kmetty A, Barany T, Karger-Kocsis J (2010) Self-reinforced polymeric materials: a review. Prog Polym Sci 35:1288–1310

Alcock B, Peijs T (2013) In: Abe A, Kausch H-H, Möller M, Pasch H (eds) Polymer composites—polyolefin fractionation—polymeric peptidomimetics—collagens. Springer, Berlin

Zhuang X, Yan X (2006) Investigation of damage mechanisms in self-reinforced polyethylene composites by acoustic emission. Compos Sci Technol 66:444–449

Balzano L, Rastogi S, Peters GWM (2008) Flow induced crystallization in isotactic polypropylene-1,3:2,4-bis(3,4-dimethylbenzylidene)sorbitol blends: implications on morphology of shear and phase separation. Macromolecules 41:399–408

Kumaraswamy G, Kornfield JA, Yeh F, Hsiao BS (2002) Shear-enhanced crystallization in isotactic polypropylene. 3. Evidence for a kinetic pathway to nucleation. Macromolecules 35:1762–1769

Papageorgiou DG, Chrissafis K, Bikiaris DN (2015) β-Nucleated polypropylene: processing, properties and nanocomposites. Polym Rev 55:1–34

Varga J (2002) beta-modification of isotactic polypropylene: preparation, structure, processing, properties, and application. J Macromol Sci B41:1121–1171

Han R, Nie M, Wang Q (2015) Control over β-form hybrid shish-kebab crystals in polypropylene pipe via coupled effect of self-assembly β nucleating agent and rotation extrusion. J Taiwan Inst Chem E 52:158

Li Y, Wen X, Nie M, Wang Q (2014) Controllable reinforcement of stiffness and toughness of polypropylene via thermally induced self-assembly of β-nucleating agent. J Appl Polym Sci. doi:10.1002/app.v131.16

Nie M, Han R, Wang Q (2014) Formation and alignment of hybrid shish-kebab morphology with rich beta crystals in an isotactic polypropylene pipe. Ind Eng Chem Res 53:4142–4146

Zhang R, Shi D, Tjong SC, Li R (2007) Study on the β to α transformation of polypropylene crystals in compatibilized blend of polypropylene/polyamide-6. J Polym Sci 45:2674–2681

Labour T, Vigier G, Seguela R, Gauthier C, Orange G, Bomal Y (2002) Influence of the β-crystalline phase on the mechanical properties of unfilled and calcium carbonate-filled polypropylene: ductile cracking and impact behavior. J Polym Sci 40:31–42

Chen HB, Karger-Kocsis J, Wu JS, Varga J (2002) Fracture toughness of α- and β-phase polypropylene homopolymers and random- and block-copolymers. Polymer 43:6505–6514

Karger-Kocsis J (1996) How does “phase transformation toughening” work in semicrystalline polymers? Polym Eng Sci 36:203–210

Olley R, Bassett D (1982) An improved permanganic etchant for polyolefines. Polymer 23:1707–1710

Padden F Jr, Keith H (1959) Spherulitic crystallization in polypropylene. J Appl Phys 30:1479–1484

Kimata S, Sakurai T, Nozue Y et al (2007) Molecular basis of the shish-kebab morphology in polymer crystallization. Science 316:1014–1017

Somani RH, Hsiao BS, Nogales A et al (2000) Structure development during shear flow-induced crystallization of i-PP: in-situ small-angle X-ray scattering study. Macromolecules 33:9385–9394

Varga J, Menyhard A (2007) Effect of solubility and nucleating duality of N,N′-dicyclohexyl-2,6-naphthalenedicarboxamide on the supermolecular structure of isotactic polypropylene. Macromolecules 40:2422–2431

Zhang C, Wang B, Yang J et al (2015) Synergies among the self-assembled β-nucleating agent and the sheared isotactic polypropylene matrix. Polymer 60:40–49

Dong M, Jia MY, Guo ZX, Yu JA (2011) Effect of final heating temperature on crystallization of isotactic polypropylene nucleated with an aryl amide derivative as beta-form nucleating agent. Chin J Polym Sci 29:308–317

Dong M, Guo ZX, Yu J, Su ZQ (2009) Study of the assembled morphology of aryl amide derivative and its influence on the nonisothermal crystallizations of isotactic polypropylene. J Polym Sci 47:314–325

Chen YH, Fang DF, Hsiao BS, Li ZM (2015) Insight into unique deformation behavior of oriented isotactic polypropylene with branched shish-kebabs. Polymer 60:274–283

Patil N, Balzano L, Portale G, Rastogi S (2010) Influence of shear in the crystallization of polyethylene in the presence of SWCNTs. Carbon 48:4116–4128

Sinclair LA, McCammond D, Kortschot MT (1992) Fracture modes of oriented polypropylene. J Reinf Plast Compos 11:1270–1285

Brady J, Thomas E (1989) Deformation of oriented high density polyethylene shish-kebab films. J Mater Sci 24:3311–3318. doi:10.1007/BF01139059

Alcock B, Cabrera NO, Barkoula NM, Loos J, Peijs T (2006) The mechanical properties of unidirectional all-polypropylene composites. Composites Part A 37:716–726

van den Oever M, Peijs T (1998) Continuous-glass-fibre-reinforced polypropylene composites II. Influence of maleic-anhydride modified polypropylene on fatigue behaviour. Composites Part A 29:227–239

Deblieck RA, Van Beek D, Remerie K, Ward IM (2011) Failure mechanisms in polyolefines: the role of crazing, shear yielding and the entanglement network. Polymer 52:2979–2990

Argon AS (1973) Physical basis of distortional and dilational plastic flow in glassy polymers. J Macromol Sci 8:573–596

Brown H (1991) A molecular interpretation of the toughness of glassy polymers. Macromolecules 24:2752–2756

Yang AC, Kramer EJ, Kuo CC, Phoenix SL (1986) Craze fibril stability and breakdown in polystyrene. Macromolecules 19:2010–2019

Kramer EJ (1984) Craze fibril formation and breakdown. Polym Eng Sci 24:761–769

Labour T, Gauthier C, Séguéla R, Vigier G, Bomal Y, Orange G (2001) Influence of the β crystalline phase on the mechanical properties of unfilled and CaCO3-filled polypropylene. I. Structural and mechanical characterisation. Polymer 42:7127–7135

Han R, Li Y, Wang Q, Nie M (2014) Critical formation conditions for β-form hybrid shish-kebab and its structural analysis. RSC Adv 4:65035–65043

Li JX, Cheung WL, Chan CM (1999) On deformation mechanisms of β-polypropylene 2. Changes of lamellar structure caused by tensile load. Polymer 40:2089–2102

Huang YL, Brown N (1988) The effect of molecular weight on sloThe effect of molecular weight on slow crack growth in linear polyethylene homopolymers. J Mater Sci 23:3648–3655. doi:10.1007/BF00540508

Huang YL, Brown N (1991) Dependence of slow crack growth in polyethylene on butyl branch density: morphology and theory. J Polym Sci 29:129–137

Brown N, Lu X, Huang YL, Qian R (1991) Makromolekulare Chemie. Macromolecular Symposia. Wiley Online Library

Acknowledgements

This work is financed by the National Natural Science Foundation of China (51127003 and 51303114), and the support provided by the Shanghai Synchronous Radiation Facility is gratefully acknowledged for providing SAXA.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, Y., Li, M., Nie, M. et al. Reinforcement for polypropylene via self-assembly of β-form nucleating agent: new insight on the perpendicular orientation of lamellae. J Mater Sci 52, 981–992 (2017). https://doi.org/10.1007/s10853-016-0393-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-016-0393-7