Abstract

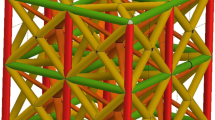

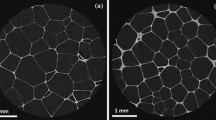

Cellular structures are present in many modern and natural materials and their proper utilization is crucial within many industries. Characterizing their structural and mechanical properties is complicated, in that they often have a stochastic cellular structure, and in addition, they often have hyper-elastic (i.e., non-linear) mechanical properties. Understanding the 3D structure and the dynamic response of polymer foams to mechanical stress is a key to predicting lifetime performance, damage pathways, and stress recovery. Therefore, to gain a more complete picture, experiments which are designed to understand their mechanical properties must simultaneously acquire performance metrics during loading. In situ synchrotron X-ray computed tomography can image these cellular materials in 3D during uniaxial compression at a 10−2 s−1 strain rate. By utilizing the high X-ray photon flux and high-speed camera provided by beamline 2-BM at the advanced photon source, it is possible to collect a full 3D tomogram (900 radiographs as the sample is rotated 180°) within 1 s. Rotating the sample stage in a washing machine motion allows for a 1 s tomogram to be collected every fifth second. In this study, a series of 20 tomograms were collected as the sample was continuously stressed to a nominal 60 % compression. Several types of silicone foams with various structures were used to explore this technique. Stress–strain curves, collected simultaneously with the 3D tomograms, can be used to directly correlate the morphology with the mechanical performance and visualize in real-time, the buckling of ligaments. In addition, this method allows for the accurate measurement of the Poisson’s ratio as a function of compression. Coupling this moderate strain rate 3D data with finite element analysis provides a direct comparison between the true mechanical response and the modeled performance and adds a level of robustness that is not possible with other techniques.

Similar content being viewed by others

References

Gibson LJ, Ashby MF (1997) Cellular solids: structure and properties. Cambridge University Press, Cambridge

Stock SR (2008) Recent advances in X-ray microtomography applied to materials. Int Mater Rev 53(3):129–181

Haware RV, Kim P, Ruffino L, Nimi B, Fadrowsky C, Doyle M, Boerrigter SXM, Cuitino A, Morris K (2011) Anisotropic crystal deformation measurements determined using powder X-ray diffraction and a new in situ compression stage. Int J Pharm 418(2):199–206. doi:10.1016/j.ijpharm.2011.06.021

Patterson BM, Obrey KAD, Hamilton CE, Havrilla GJ (2012) Three-dimensional density measurements of ultra low density materials by X-ray scatter using confocal micro X-ray fluorescence spectroscopy. XRay Spectrom 41(4):253–258

Cordes NL, Havrilla GJ, Usov IO, Obrey KA, Patterson BM (2014) Non-destructive elemental quantification of polymer-embedded thin films using laboratory based X-ray techniques. Spectrochim Acta B 101:320–329. doi:10.1016/j.sab.2014.09.016

Tsuji K, Nakano K, Ding X (2007) Development of confocal micro X-ray fluorescence instrument using two X-ray beams. Spectrochim Acta B 62(6–7):549–553. doi:10.1016/j.sab.2007.02.014

Dattelbaum DM, Gustavsen RL, Sheffield SA, Stahl DB, Scharff RJ, Rigg PA, Furmanski J, Orler EB, Patterson B, Coe JD (2012) The dynamic response of carbon fiber-filled polymer composites. EPJ Web Conf 26:02007

Patterson BM, Henderson K, Smith Z (2013) Measure of morphological and performance properties in polymeric silicone foams by X-ray tomography. J Mater Sci 48(5):1986–1996. doi:10.1007/s10853-012-6965-2

Patterson BM, Henderson K, Smith Z, Zhang D, Giguere P (2012) Application of micro X-ray tomography to in-situ foam compression and numerical modeling. Microsc Anal 26(2):S4–S7

Patterson BM, Henderson K, Gilbertson RD, Tornga S, Cordes NL, Chavez ME, Smith Z (2014) Morphological and performance measures of polyurethane foams using X-ray CT and mechanical testing. Microsc Microanal 95:18–26

Buffiere JY, Maire E, Adrien J, Masse JP, Boller E (2010) In situ experiments with X ray tomography: an attractive tool for experimental mechanics. Exp Mech 50(3):289–305. doi:10.1007/s11340-010-9333-7

Elliott JA, Windle AH, Hobdell JR, Eeckhaut G, Oldman RJ, Ludwig W, Boller E, Cloetens P, Baruchel J (2002) In-situ deformation of an open-cell flexible polyurethane foam characterised by 3D computed microtomography. J Mater Sci 37(8):1547–1555. doi:10.1023/a:1014920902712

Adrien J, Maire E, Gimenez N, Sauvant-Moynot V (2007) Experimental study of the compression behaviour of syntactic foams by in situ X-ray tomography. Acta Mater 55(5):1667–1679. doi:10.1016/j.actamat.2006.10.027

Shearing PR, Bradley RS, Gelb J, Lee SN, Atkinson A, Withers PJ, Brandon NP (2011) Using synchrotron X-ray nano-CT to characterize SOFC electrode microstructures in three-dimensions at operating temperature. Electrochem Solid State Lett 14(10):B117–B120

Fife JL, Rappaz M, Pistone M, Celcer T, Mikuljan G, Stampanoni M (2012) Development of a laser-based heating system for in situ synchrotron-based X-ray tomographic microscopy. J Synchrotron Radiat 19(3):352–358. doi:10.1107/S0909049512003287

Maire E, Elmoutaouakkil A, Fazekas A, Salvo L (2003) In situ X-ray tomography measurements of deformation in cellular solids. MRS Bull 28:284–289

Maire E, Paolo C, Jerome A, Laurent B, Biasetto L (2007) Characterization of the morphology of cellular ceramics by 3D image processing of X-ray tomography. J Eur Ceram Soc 27(4):1973–1981

Burteau A, N’Guyen F, Bartout JD, Forest S, Bienvenu Y, Saberi S, Naumann D (2012) Impact of material processing and deformation on cell morphology and mechanical behavior of polyurethane and nickel foams. Int J Solids Struct 49(19–20):2714–2732. doi:10.1016/j.ijsolstr.2012.05.026

Williams JJ, Yazzie KE, Padilla E, Chawla N, Xiao X, De Carlo F (2013) Understanding fatigue crack growth in aluminum alloys by in situ X-ray synchrotron tomography. Int J Fatigue 57:79–85. doi:10.1016/j.ijfatigue.2012.06.009

Hruby P, Singh SS, Williams JJ, Xiao X, De Carlo F, Chawla N (2014) Fatigue crack growth in SiC particle reinforced Al alloy matrix composites at high and low R-ratios by in situ X-ray synchrotron tomography. Int J Fatigue 68:136–143. doi:10.1016/j.ijfatigue.2014.05.010

Singh SS, Williams JJ, Lin MF, Xiao X, De Carlo F, Chawla N (2014) In situ investigation of high humidity stress corrosion cracking of 7075 aluminum alloy by three-dimensional (3D) X-ray synchrotron tomography. Mater Res Lett 2(4):217–220. doi:10.1080/21663831.2014.918907

Singh S, Williams J, Hruby P, Xiao X, De Carlo F, Chawla N (2014) In situ experimental techniques to study the mechanical behavior of materials using X-ray synchrotron tomography. Integr Mater Manuf Innov 3(1):9

Xie HX, Friedman D, Mirpuri K, Chawla N (2014) Electromigration damage characterization in Sn–3.9Ag–0.7Cu and Sn–3.9Ag–0.7Cu–0.5Ce solder joints by three-dimensional X-ray tomography and scanning electron microscopy. J Elec Mater 43(1):33–42. doi:10.1007/s11664-013-2667-z

Chao W, Harteneck BD, Liddle JA, Anderson EH, Attwood DT (2005) Soft X-ray microscopy at a spatial resolution better than 15 nm. Nature 435(7046):1210–1213

Chapman NC, Silva J, Williams JJ, Chawla N, Xiao X (2015) Characterisation of thermal cycling induced cavitation in particle reinforced metal matrix composites by three-dimensional (3D) X-ray synchrotron tomography. Mater Sci Technol 31(5):573–578. doi:10.1179/1743284714Y.0000000582

Viot P, Bernard D (2006) Impact test deformations of polypropylene foam samples followed by microtomography. J Mater Sci 41(4):1277–1279. doi:10.1007/s10853-005-2332-x

Viot P, Bernard D, Plougonven E (2007) Polymeric foam deformation under dynamic loading by the use of the microtomographic technique. J Mater Sci 42(17):7202–7213. doi:10.1007/s10853-006-1422-8

Brown EN, Furmanski J, Ramos KJ, Dattelbaum DM, Jensen BJ, Iverson AJ, Carlson CA, Fezzaa K, Gray GT III, Patterson BM, Trujillo CP, Martinez DT, Pierce TH (2014) High-density polyethylene damage at extreme tensile conditions. J Phys 500(11):112011

Clarke A, Imhoff S, Cooley J, Patterson B, Lee W-K, Fezzaa K, Deriy A, Tucker T, Katz MR, Gibbs P, Clarke K, Field RD, Thoma DJ, Teter DF (2013) X-ray imaging of Al-7 at.% Cu during melting and solidification. Emerg Mater Res 2(2):90–98

Tolnai D, Townsend P, Requena G, Salvo L, Lendvai J, Degischer HP (2012) In situ synchrotron tomographic investigation of the solidification of an AlMg4.7Si8 alloy. Acta Mater 60(6–7):2568–2577. doi:10.1016/j.actamat.2012.01.024

Limodin N, Salvo L, Boller E, Suery M, Felberbaum M, Gailliegue S, Madi K (2009) In situ and real-time 3D microtomography investigation of dendritic solidification in an Al-10 wt.% Cu alloy. Acta Mater 57:2300–2310

Walker SM, Schwyn DA, Mokso R, Wicklein M, Müller T, Doube M, Stampanoni M, Krapp HG, Taylor GK (2014) In vivo time-resolved microtomography reveals the mechanics of the blowfly flight motor. PLoS Biol 12(3):e1001823. doi:10.1371/journal.pbio.1001823

Gaitanaros S, Kyriakides S, Kraynik AM (2012) On the crushing response of random open-cell foams. Int J Solids Struct 49(19–20):2733–2743. doi:10.1016/j.ijsolstr.2012.03.003

Dudek MA, Hunter L, Kranz S, Williams JJ, Lau SH, Chawla N (2010) Three-dimensional (3D) visualization of reflow porosity and modeling of deformation in Pb-free solder joints. Mater Charact 61:433–439

Morrell PR, Patel M, Pitts S (2012) X-ray CT microtomography and mechanical response of foamed polysiloxane elastomers. Polym Test 31:102–109

Patterson BM, Hamilton CE (2010) Dimensional standard for micro X-ray computed tomography. Anal Chem 82(20):8537–8543. doi:10.1021/ac101522q

De Carlo F, Tieman B (2004) High-throughput X-ray microtomography system at the Advanced Photon Source beamline 2-BM. In: Proceedings of the SPIE 5535, developments in X-ray tomography, vol IV(5535), pp 644–651)

De Carlo F, Albee PB, Chu YS, Mancini DC, Tieman B, Wang SY (2002) High-throughput real-time x-ray microtomography at the advanced photon source. In: Proceedings of the SPIE 4503, developments in X-ray tomography, vol III(4503), pp 1–13

Williams JJ, Chapman NC, Jakkali V, Tanna VA, Chawla N, Xiao X, De Carlo F (2011) Characterization of damage evolution in SiC particle reinforced Al alloy matrix composites by in-situ X-ray synchrotron tomography. Metall Mater Trans A 42(10):2999–3005

Gursoy D, De Carlo F, Xiao X, Jacobsen C (2014) TomoPy: a framework for the analysis of synchrotron tomographic data. J Synchrotron Radiat 21(5):1188–1193. doi:10.1107/S1600577514013939

Weickert J, Romeny BMTH, Viergever MA (1998) Efficient and reliable schemes for nonlinear diffusion filtering. Image Proc IEEE Trans 7(3):398–410. doi:10.1109/83.661190

Bezazi A, Scarpa F (2007) Mechanical behaviour of conventional and negative Poisson’s ratio thermoplastic polyurethane foams under compressive cyclic loading. Int J Fatigue 29(5):922–930. doi:10.1016/j.ijfatigue.2006.07.015

Pierron F, McDonald SA, Hollis D, Withers PJ, Alderson A (2011) Assessment of the deformation of low density polymeric auxetic foams by X-ray tomography and digital volume correlation. Appl Mech Mater 70:93–98

Poveda R, Gupta N, Porfiri M (2010) Poisson’s ratio of hollow particle filled composites. Mater Lett 64:2360–2362

Gibson LJ, Ashby MF (1997) Cellular solids: structures and properties. In: Clarke DR, Suresh S, Ward IM (eds) Cambridge solid state science series, 2nd edn. Cambridge University Press, Cambridge, pp 176–177

Gibson LJ, Ashby MF (1997) Cellular solids: structures and properties. In: Clarke DR, Suresh S, Ward IM (eds) Cambridge solid state science series, 2nd edn. Cambridge University Press, Cambridge, pp 192–197

Lee T, Lakes RS (1997) Anisotropic polyurethane foam with Poisson’s ratio greater than 1. J Mater Sci 32(9):2397–2401. doi:10.1023/a:1018557107786

Widdle RD Jr, Bajaj AK, Davies P (2008) Measurement of the Poisson’s ratio of flexible polyurethane foam and its influence on a uniaxial compression model. Int J Eng Sci 46(1):31–49. doi:10.1016/j.ijengsci.2007.09.002

Tymrak BM, Kreiger M, Pearce JM (2014) Mechanical properties of components fabricated with open-source 3-D printers under realistic environmental conditions. Mater Des 58:242–246

Mohan KA, Venkatakrishnan SV, Gibbs JW, Gulsoy EB, Xiao X, De Graef M, Voorhees PW, Bouman CA (2015) TIMBIR: a method for time-space reconstruction from interlaced views. Comput Imag IEEE Trans 99:1. doi:10.1109/tci.2015.2431913

Acknowledgements

The authors wish to thank Doga Gursoy with his advice in using Tomopy and Tim Mooney for programming the beamline operation. Los Alamos National Laboratory is operated by Los Alamos National Security LLC under contract number DE-AC52-06NA25396 for the US Department of Energy. This research used resources of the Advanced Photon Source, a U. S. Department of Energy (DOE) Office of Science User Facility operated for the DOE Office of Science by Argonne National Laboratory under Contract No. DE-AC02-06CH11357. Funding for this research was provided by the Enhanced Surveillance Campaign, Tom Zocco, Program Manager and the Engineering Campaign, Eric Mas, Program Manager.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Patterson, B.M., Cordes, N.L., Henderson, K. et al. In situ X-ray synchrotron tomographic imaging during the compression of hyper-elastic polymeric materials. J Mater Sci 51, 171–187 (2016). https://doi.org/10.1007/s10853-015-9355-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-015-9355-8