Abstract

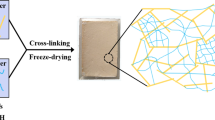

Ethylene-vinyl acetate (EVA) nanocomposites based on halloysite nanotubes (HNT) were prepared by solution casting method. The thermal, mechanical, water uptake, as well as oxygen permeability properties of the nanocomposites were examined. X-ray diffraction (XRD) and field emission scanning electron microscopy showed that HNTs were dispersed well into the EVA matrix. XRD data also suggested that HNT frustrates chain ordering and reduced total crystallinity percentage. The thermal and mechanical properties of the nanocomposites were improved with HNT loading, up to 3 wt%. Both ductility and toughness were enhanced by incorporation of up to 3 wt% of HNT, implicitly confirming that HNT has been dispersed in EVA homogeneously. The addition of HNT also enhanced the water resistance and oxygen permeability of the prepared nanocomposites.

Similar content being viewed by others

References

González-Benito J, Castillo E, Caldito JF (2013) Coefficient of thermal expansion of TiO2 filled EVA based nanocomposites. A new insight about the influence of filler particle size in composites. Eur Polym J 49(7):1747–1752

Dehsari HS et al (2014) Efficient preparation of ultralarge graphene oxide using a PEDOT: PSS/GO composite layer as hole transport layer in polymer-based optoelectronic devices. RSC Advances 4(98):55067–55076

Spitalsky Z et al (2010) Carbon nanotube–polymer composites: chemistry, processing, mechanical and electrical properties. Prog Polym Sci 35(3):357–401

Giannelis EP (1996) Polymer layered silicate nanocomposites. Adv Mater 8(1):29–35

Alhuthali A, Low IM (2013) Water absorption, mechanical, and thermal properties of halloysite nanotube reinforced vinyl-ester nanocomposites. J Mater Sci 48(12):4260–4273. doi:10.1007/s10853-013-7240-x

Hao A et al (2014) Mechanical, thermal, and flame-retardant performance of polyamide 11–halloysite nanotube nanocomposites. J Mater Sci. doi:10.1007/s10853-014-8575-7

Liu M et al (2014) Recent advance in research on halloysite nanotubes-polymer nanocomposite. Prog Polym Sci 39(8):1498–1525

Hashemifard SA, Ismail AF, Matsuura T (2011) Mixed matrix membrane incorporated with large pore size halloysite nanotubes (HNT) as filler for gas separation: experimental. J Colloid Interface Sci 359(2):359–370

Pasbakhsh P et al (2010) EPDM/modified halloysite nanocomposites. Appl Clay Sci 48(3):405–413

Rooj S et al (2010) Preparation and properties of natural nanocomposites based on natural rubber and naturally occurring halloysite nanotubes. Mater Des 31(4):2151–2156

Carli LN, Crespo JS, Mauler RS (2011) PHBV nanocomposites based on organomodified montmorillonite and halloysite: the effect of clay type on the morphology and thermal and mechanical properties. Compos A Appl Sci Manuf 42(11):1601–1608

Hedicke-Höchstötter K, Lim GT, Altstädt V (2009) Novel polyamide nanocomposites based on silicate nanotubes of the mineral halloysite. Comp Sci Technol 69(3–4):330–334

Jang D, Zhang W, Choi H (2014) Polypyrrole-wrapped halloysite nanocomposite and its rheological response under electric fields. J Mater Sci 49(20):7309–7316. doi:10.1007/s10853-014-8443-5

Deng S et al (2008) Toughening epoxies with halloysite nanotubes. Polymer 49(23):5119–5127

Liu M et al (2008) Natural inorganic nanotubes reinforced epoxy resin nanocomposites. J Polym Res 15(3):205–212

Ning N-Y et al (2007) Crystallization behavior and mechanical properties of polypropylene/halloysite composites. Polymer 48(25):7374–7384

Du M, Guo B, Jia D (2006) Thermal stability and flame retardant effects of halloysite nanotubes on poly (propylene). Eur Polym J 42(6):1362–1369

Ismail H et al (2008) Morphological, thermal and tensile properties of halloysite nanotubes filled ethylene propylene diene monomer (EPDM) nanocomposites. Polym Testing 27(7):841–850

Guo B et al (2009) Styrene-butadiene rubber/halloysite nanotubes nanocomposites modified by sorbic acid. Appl Surf Sci 255(16):7329–7336

Guo B et al (2008) Styrene–butadiene rubber/halloysite nanotubes nanocomposites modified by methacrylic acid. Appl Surf Sci 255(5):2715–2722

Du M et al (2008) Carboxylated butadiene–styrene rubber/halloysite nanotube nanocomposites: interfacial interaction and performance. Polymer 49(22):4871–4876

Soheilmoghaddam M et al (2013) Regenerated cellulose/halloysite nanotube nanocomposite films prepared with an ionic liquid. Mater Chem Phys 141(2–3):936–943

Hanid NA et al (2014) Development of regenerated cellulose/halloysites nanocomposites via ionic liquids. Carbohydr Polym 99:91–97

De Silva RT et al (2014) Influence of the processing methods on the properties of poly(lactic acid)/halloysite nanocomposites. Polym Comps. doi:10.1002/pc.23244

Schmitt H et al (2012) Preparation and properties of novel melt-blended halloysite nanotubes/wheat starch nanocomposites. Carbohydr Polym 89(3):920–927

Sengupta R et al (2011) A review on the mechanical and electrical properties of graphite and modified graphite reinforced polymer composites. Prog Polym Sci 36(5):638–670

Kim H, Abdala AA, Macosko CW (2010) Graphene/polymer nanocomposites. Macromolecules 43(16):6515–6530

Bidsorkhi HC et al (2014) Mechanical, thermal and flammability properties of ethylene-vinyl acetate (EVA)/sepiolite nanocomposites. Polym Testing 37:117–122

Zanetti M et al (2001) Synthesis and thermal behaviour of layered silicate–EVA nanocomposites. Polymer 42(10):4501–4507

Riva A et al (2002) Thermal degradation and rheological behaviour of EVA/montmorillonite nanocomposites. Polym Degrad Stab 77(2):299–304

Tian Y et al (2004) Study on the structure and properties of EVA/clay nanocomposites. J Mater Sci 39(13):4301–4303. doi:10.1023/B:JMSC.0000033412.92494.ee

Morlat-Therias S et al (2007) Polymer/carbon nanotube nanocomposites: influence of carbon nanotubes on EVA photodegradation. Polym Degrad Stab 92(10):1873–1882

Kim S et al (2007) Polysulfone and functionalized carbon nanotube mixed matrix membranes for gas separation: theory and experiment. J Membr Sci 294(1–2):147–158

Wang B, Huang H-X (2013) Effects of halloysite nanotube orientation on crystallization and thermal stability of polypropylene nanocomposites. Polym Degrad Stab 98(9):1601–1608

Marcilla A et al (2005) Pyrolysis of polymers in the presence of a commercial clay. Polym Degrad Stab 88(3):456–460

Yuan P et al (2008) Functionalization of halloysite clay nanotubes by grafting with γ-aminopropyltriethoxysilane. J Phys Chem C 112(40):15742–15751

Sadeghi M et al (2008) Gas permeation properties of ethylene vinyl acetate–silica nanocomposite membranes. J Membr Sci 322(2):423–428

Soheilmoghaddam M, Wahit MU (2013) Development of regenerated cellulose/halloysite nanotube bionanocomposite films with ionic liquid. Int J Biol Macromol 58:133–139

Guo B et al (2009) Crystallization behavior of polyamide 6/halloysite nanotubes nanocomposites. Thermochim Acta 484(1):48–56

Urresti O et al (2011) Oxygen permeability through poly(ethylene-co-vinyl acetate)/clay nanocomposites prepared by microwave irradiation. J Membr Sci 373(1–2):173–177

Hoang T et al (2013) Tensile, rheological properties, thermal stability, and morphology of ethylene vinyl acetate copolymer/silica nanocomposites using EVA-g-maleic anhydride. J Comp Mater. doi:10.1177/0021998313476319

Bai Y et al (2007) Pervaporation characteristics of ethylene–vinyl acetate copolymer membranes with different composition for recovery of ethyl acetate from aqueous solution. J Membr Sci 305(1):152–159

Devallencourt C et al (2002) Study of transport of small molecules through ethylene-co-vinyl acetate copolymers films. Part A: Water molecules. Polym Testing 21(3):253–262

Mishra S, Luyt A (2008) Effect of organic peroxides on the morphological, thermal and tensile properties of EVA-organoclay nanocomposites. express. Polym Lett 2:256–264

Wilson R et al (2012) Clay intercalation and its influence on the morphology and transport properties of EVA/clay nanocomposites. J Phys Chem C 116(37):20002–20014

Arsac A, Carrot C, Guillet J (1999) Rheological characterization of ethylene vinyl acetate copolymers. J Appl Polym Sci 74(11):2625–2630

Han D et al (2011) Cellulose/graphite oxide composite films with improved mechanical properties over a wide range of temperature. Carbohydr Polym 83(2):966–972

Soheilmoghaddam M et al (2014) Characterization of bio regenerated cellulose/sepiolite nanocomposite films prepared via ionic liquid. Polym Testing 33:121–130

Soheilmoghaddam M et al (2014) Bionanocomposites of regenerated cellulose/zeolite prepared using environmentally benign ionic liquid solvent. Carbohydr Polym 106:326–334

Gavgani JN et al (2014) Intumescent flame retardant polyurethane/starch composites: Thermal, mechanical, and rheological properties. J Appl Polym Sci 131:41158. doi:10.1002/app.41158

He Y et al (2012) Modified natural halloysite/potato starch composite films. Carbohydr Polym 87(4):2706–2711

Liu M et al (2012) Chitosan/halloysite nanotubes bionanocomposites: structure, mechanical properties and biocompatibility. Int J Biol Macromol 51(4):566–575

Liu M, Zhang Y, Zhou C (2013) Nanocomposites of halloysite and polylactide. Appl Clay Sci 75:52–59

Pramanik M et al (2003) EVA/clay nanocomposite by solution blending: effect of aluminosilicate layers on mechanical and thermal properties. Macromol Res 11(4):260–266

Khodkar F, Ebrahimi NG (2011) Effect of irradiation on mechanical and structural properties of ethylene vinyl acetate copolymers hollow fibers. J Appl Polym Sci 119(4):2085–2092

Gavgani J, Adelnia H, Gudarzi M (2014) Intumescent flame retardant polyurethane/reduced graphene oxide composites with improved mechanical, thermal, and barrier properties. J Mater Sci 49(1):243–254. doi:10.1007/s10853-013-7698-6

Swain SK et al (2013) Cellulose nanobiocomposites with reinforcement of boron nitride: study of thermal, oxygen barrier and chemical resistant properties. Carbohydr Polym 95(2):728–732

Ghosal K, Freeman BD (1994) Gas separation using polymer membranes: an overview. Polym Adv Technol 5(11):673–697

Liu M et al (2012) Novel polymer nanocomposite hydrogel with natural clay nanotubes. Colloid Polym Sci 290(10):895–905

Acknowledgements

Our special thanks are due to Zhaleh Nayebossadrian for her kind and great help.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bidsorkhi, H.C., Adelnia, H., Heidar Pour, R. et al. Preparation and characterization of ethylene-vinyl acetate/halloysite nanotube nanocomposites. J Mater Sci 50, 3237–3245 (2015). https://doi.org/10.1007/s10853-015-8891-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-015-8891-6