Abstract

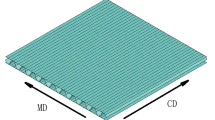

Understanding heat transfer in corrugated fibreboard is important to the design of more effective packaging for industries which involve the freezing and chilling of food. In this work the thermal conductivity of papers which compose corrugated fibreboard were measured and used to validate finite element models of heat transfer in fibreboard. The results showed paper to be highly anisotropic, with thermal conductivity in the machine and cross machine directions being almost an order of magnitude larger than in the thickness direction. The finite element models showed good agreement with experimental results and demonstrated that the majority of heat transfer in corrugated fibreboard is though the fluted medium. Based on the finite element models, simple models for the prediction of the thermal performance of corrugated board were evaluated and shown to be very effective in reproducing the results of the more complex finite element methods. These simple methods can be used to perform corrugated fibreboard design calculations, and the models with and without radiation can be used to provide estimates of the lower and upper bounds of the thermal resistance for a given board design.

Graphical abstract

Similar content being viewed by others

References

Bormett DW (1981) Overall effective thermal resistance of corrugated fibreboard. Research paper No. FSRP-FPL-406. Forest Products Lac, Madison WI

Bronlund JE, Robertson TR (2006) Modelling of heat transfer through corrugated cardboard packaging. In: IIR/IHRACE conference, Auckland

Bronlund JE, Redding GP, Robertson TR (2014) Modelling steady-state moisture transport through corrugated fibreboard packaging. Packag Technol Sci 27:193–201

Choi S, Burgess G (2007) Practical mathematical model to predict the performance of insulating packages. Packag Technol Sci 20:369–380

Cleland AC, Earle RL (1976) A new method for prediction of surface heat transfer coefficients in freezing. In: Bulletin. Annex-International Institute of Refrigeration (IIR), Refrigeration Science and Technology. 1976-1, pp 361–368

COMSOL Multiphysics® v. 4.4. www.comsol.com. COMSOL AB, Stockholm, Sweden

de Castro LR, Vigneault C, Cortex LAB (2004) Container opening design for horticultural produce cooling efficiency. J Food Agric Environ 2:135–140

Heat Transfer Users Guide (2013) COMSOL. Stockholm, Sweden, pp 188–190

Imakoma H, Yano T, Kubota K, Ohomura N, Kataoka K (2000) Moisture content dependence of anisotropic effective thermal conductivity for recycled paper. Kagaku Kogaku Ronbunshu 26:105–107

Incropera FP, Lavine AS, Bergman TL, DeWitt DP (2007) Fundamentals of heat and mass transfer. Wiley, New York

McCabe WL, Smith JC, Harriott P (1993) Unit operations of chemical engineering, vol 1130. McGraw-Hill, New York

Mikheyev M (1968) Fundamentals of heat transfer. Mir, Moscow

Moureh J, Derens E (2000) Numerical modelling of the temperature increase in frozen food packaged in pallets in the distribution chain. Int J Refrig 23:540–552

Ramaker TJ (1974) Thermal resistance of corrugated fibreboard. Tappi 59:69–72

Robertson TR, Thompson FB, Cleland AC (1998) Measuring thermal resistance of corrugated made simple. Packag Technol Eng 7:48–51

Thompson FB, Robertson TR, Cleland AC (1999) Modelling the heat transfer resistance of corrugated paperboard. N Z Food J 29:94–97

Twede D, Harte B (2003) Logistical packaging for food marketing systems. In: Cole R, McDowell D, Kirwan M (eds) Food packaging technology. Blackwell Publishing, Oxford

Urbanik TJ (2001) Effect of corrugated flute shape on fibreboard edgewise crush strength and bending stiffness. J Pulp Pap Sci 27:330–335

Zapata PA, Fransen M, ten Thije BJ, Saes L (2013) Coupled heat and moisture transport in paper with application to a warm print surface. Appl Math Model 37:7273–7286

Acknowledgments

The authors would like to thank SCION for their support on this project.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Gray-Stuart, E.M., Bronlund, J.E., Navaranjan, N. et al. Measurement of thermal conductivity of paper and corrugated fibreboard with prediction of thermal performance for design applications. Cellulose 26, 5695–5705 (2019). https://doi.org/10.1007/s10570-019-02462-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-019-02462-5