Abstract

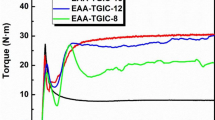

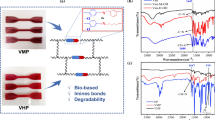

In order to extend the application of epoxy vitrimer, 1,4-cyclohexanedicarboxylic acid (CHDA) was used as a co-curing agent and structure modifier for sebacic acid (SA) cured diglycidyl ether of bisphenol A (DGEBA) epoxy vitrimer to tailor the mechanical properties of epoxy vitrimers with 1,5,7-triazabicylo[4.4.0]dec-5-ene (TBD) as a transesterification catalyst. The glass transition temperature (Tg) of vitrimer increased gradually with the increase in CHDA content. Vitrimers behaved from elastomer to tough and hard plastics were successfully achieved by varying the feed ratio of CHDA to SA. Both the Young’s modulus and storage modulus increased apparently with the increase in CHDA content. Stress relaxation measurement indicated that more prominent stress relaxation occurred at elevated temperatures and the stress relaxation decreased with the increase of CHDA content due to the reduced mobility of the vitrimer backbone. The vitrimers showed excellent recyclability as evidenced by the unchanged gel fraction and mechanical properties after compression molded for several times. With tunable mechanical properties, the epoxy vitrimers may find extensive potential applications.

Similar content being viewed by others

References

Montarnal, D.; Capelot, M.; Tournilhac, F.; Leibler, L. Silica-like malleable materials from permanent organic networks. Science 2011, 334(6058), 965–968.

Brutman, J. P.; Delgado, P. A.; Hillmyer, M. A. Polylactide vitrimers. ACS Macro Lett. 2014, 3(7), 607–610.

Maeda, T.; Otsuka, H.; Takahara, A. Dynamic covalent polymers: reorganizable polymers with dynamic covalent bonds. Prog. Polym. Sci. 2009, 34(7), 581–604.

Wojtecki, R. J.; Meador, M. A.; Rowan, S. J. Using the dynamic bond to access macroscopicallyresponsive structurally dynamic polymers. Nat. Mater. 2011, 10(1), 14–27.

Azcune, I.; Odriozola, I. Aromatic disulfide crosslinks in polymer systems: self-healing, reprocessability, recyclability and more. Eur. Polym. J. 2016, 84, 147–160.

Kloxin, C. J.; Scott, T. F.; Adzima, B. J.; Bowman, C. N. Covalent adaptable networks (CANs): aunique paradigm in cross-linked polymers. Macromolecules 2010, 43(6), 2643–2653.

Kloxin, C. J.; Bowman, C. N. Covalent adaptable networks: smart, reconfigurable and responsive network systems. Chem. Soc. Rev. 2013, 42(17), 7161–7173.

Adzima, B. J.; Aguirre, H. A.; Kloxin, C. J.; Scott, T. F.; Bowman, C. N. Rheological and chemical analysis of reverse gelation in a covalently cross-linked Diels-Alder polymer network. Macromolecules 2008, 41(23), 9112–9117.

Chen, X.; Dam, M. A.; Ono, K.; Mal, A.; Shen, H.; Nutt, S. R.; Sheran, K.; Wudl, F. A thermally re-mendable cross-linked polymeric material. Science 2002, 295(5560), 1698–1702.

Zhang, J.; Niu, Y.; Huang, C.; Xiao, L.; Chen, Z.; Yang, K.; Wang, Y. Self-healable and recyclable triple-shape PPDO-PTMEG co-network constructed through thermoreversible Diels-Alder reaction. Polym. Chem. 2012, 3(6), 1390–1393.

Tasdelen, M. A. Diels-Alder “click” reactions: recent applications in polymer and material science. Polym. Chem. 2011, 2(10), 2133–2145.

Johnson, L. M.; Ledet, E.; Huffman, N. D.; Swarner, S. L.; Shepherd, S. D.; Durham, P. G.; Rothrock, G. D. Controlled degradation of disulfide-based epoxy thermosets for extreme environments. Polymer 2015, 64, 84–92.

Ruiz de Luzuriaga, A.; Martin, R.; Markaide, N.; Rekondo, A.; Cabanero, G.; Rodriguez, J.; Odriozola, I. Epoxy resin with exchangeable disulfide crosslinks to obtain reprocessable, repairable and recyclable fiber-reinforced thermoset composites. Mater. Horiz. 2016, 3(3), 241–247.

Ruiz de Luzuriaga, A.; Matxain, J. M.; Ruiperez, F.; Martin, R.; Asua, J. M.; Cabanero, G.; Odriozola, I. Transient mechanochromism in epoxy vitrimer composites containing aromatic disulfide crosslinks. J. Mater. Chem. C 2016, 4(26), 6220–6223.

Xu, C. H.; Cao, L. M.; Lin, B. F.; Liang, X. Q.; Chen, Y. K. Design of self-healing supramolecular rubbers by introducing ionic cross-links into natural rubber via a controlled vulcanization. ACS Appl. Mater. Interfaces 2016, 8(27), 17728–17737.

Capelot, M.; Montarnal, D.; Tournilhac, F.; Leibler, L. Metal-catalyzed transesterification for healing and assembling of thermosets. J. Am. Chem. Soc. 2012, 134(18), 7664–7667.

Fortman, D. J.; Brutman, J. P.; Cramer, C. J.; Hillmyer, M. A.; Dichtel, W. R. Mechanically activated, catalyst-free polyhydroxyurethane vitrimers. J. Am. Chem. Soc. 2015, 137(44), 14019–14022.

Taynton, P.; Yu, K.; Shoemaker, R. K.; Jin, Y.; Qi, H. J.; Zhang, W. Heat- or water-driven malleability in a highly recyclable covalent network polymer. Adv. Mater. 2014, 26(23), 3938–3942.

Denissen, W.; Winne, J. M.; Du Prez, F. E. Vitrimers: permanent organic networks with glass-like fluidity. Chem. Sci. 2016, 7(1), 30–38.

Gu, H.; Ma, C.; Gu, J.; Guo, J.; Yan, X.; Huang, J.; Zhang, Q.; Guo, Z. An overview of multifunctional epoxy nanocomposites. J. Mater. Chem. C 2016, 4(25), 5890–5906.

Auvergne, R.; Caillol, S.; David, G.; Boutevin, B.; Pascault, J. P. Biobased thermosetting epoxy: present and future. Chem. Rev. 2014, 114(2), 1082–1115.

Wan, J.; Zhao, J.; Gan, B.; Li, C.; Molina-Aldareguia, J.; Zhao, Y.; Pan, Y. T.; Wang, D. Y. Ultrastiff biobased epoxy resin with high T g and low permittivity: from synthesis to properties. ACS Sustain. Chem. Eng. 2016, 4(5), 2869–2880.

Yang, S.; Chen, J. S.; Körner, H.; Breiner, T.; Ober, C. K.; Poliks, M. D. Reworkable epoxies: thermosets with thermally cleavable groups for controlled network breakdown. Chem. Mater. 1998, 10(6), 1475–1482.

Pei, Z.; Yang, Y.; Chen, Q.; Terentjev, E. M.; Wei, Y.; Ji, Y. Mouldable liquid-crystalline elastomer actuators with exchangeable covalent bonds. Nat. Mater. 2014, 13(1), 36–41.

Yang, Y.; Pei, Z.; Zhang, X.; Tao, L.; Wei, Y.; Ji, Y. Carbon nanotube-vitrimer composite for facile and efficient photo-welding of epoxy. Chem. Sci. 2014, 5(9), 3486–3492.

Chabert, E.; Vial, J.; Cauchois, J. P.; Mihaluta, M.; Tournilhac, F. Multiple welding of long fiber epoxy vitrimer composites. Soft Matter 2016, 12(21), 4838–4845.

Demongeot, A.; Mougnier, S. J.; Okada, S.; Soulie-Ziakovic, C.; Tournilhac, F. Coordination and catalysis of Zn2+ in epoxy-based vitrimers. Polym. Chem. 2016, 7(27), 4486–4493.

Imbernon, L.; Norvez, S.; Leibler, L. Stress relaxation and self-adhesion of rubbers with exchangeable links. Macromolecules 2016, 49(6), 2172–2178.

Legrand, A.; Soulie-Ziakovic, C. Silica-epoxy vitrimer nanocomposites. Macromolecules 2016, 49(16), 5893–5902.

Pei, Z.; Yang, Y.; Chen, Q.; Wei, Y.; Ji, Y. Regional shape control of strategically assembled multishape memory vitrimers. Adv. Mater. 2016, 28(1), 156–160.

Yang, Y.; Pei, Z.; Li, Z.; Wei, Y.; Ji, Y. Making and remaking dynamic 3D structures by shining light on flat liquid crystalline vitrimer films without a mold. J. Am. Chem. Soc. 2016, 138(7), 2118–2121.

Yang, Z.; Wang, Q.; Wang, T. Dual-triggered and thermally reconfigurable shape memory graphene-vitrimer composites. ACS Appl. Mater. Interfaces 2016, 8(33), 21691–21699.

Altuna, F. I.; Hoppe, C. E.; Williams, R. J. J. Shape memory epoxy vitrimers based on DGEBA crosslinked with dicarboxylic acids and their blends with citric acid. RSC Adv. 2016, 6(91), 88647–88655.

Zeng, J. B.; Li, Y. D.; Zhu, Q. Y.; Yang, K. K.; Wang, X. L.; Wang, Y. Z. A novel biodegradable multiblock poly(ester urethane) containing poly(L-lactic acid) and poly(butylene succinate) blocks. Polymer 2009, 50(5), 1178–1186.

Vinogradov, G. V.; Isayev, A. I.; Katsyutsevich, E. V. Critical regimes of oscillatory deformation of polymeric systems above glass transition and melting temperatures. J.p Apl. Polym. Sci. 1978, 22(3), 727–749.

Denissen, W.; Rivero, G.; Nicolay, R.; Leibler, L.; Winne, J. M.; Du Prez, F. E. Vinylogous urethane vitrimers. Adv. Funct. Mater. 2015, 25(16), 2451–2457.

Capelot, M.; Unterlass, M. M.; Tournilhac, F.; Leibler, L. Catalytic control of the vitrimer glass transition. ACS Macro Lett. 2012, 1(7), 789–792.

Acknowledgments

This work was financially supported by the National Natural Science Foundation of China (No. 51703188) and Fundamental Research Funds for the Central Universities (Nos. XDJK2017A016 and XDJK2017C022).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Chen, JH., An, XP., Li, YD. et al. Reprocessible Epoxy Networks with Tunable Physical Properties: Synthesis, Stress Relaxation and Recyclability. Chin J Polym Sci 36, 641–648 (2018). https://doi.org/10.1007/s10118-018-2027-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10118-018-2027-9