Abstract

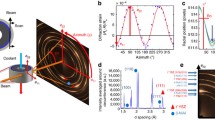

A setup of blown film machine combined with in situ synchrotron radiation X-ray diffraction measurements and infrared temperature testing is reported to study the structure evolution of polymers during film blowing. Two homemade auto-lifters are constructed and placed under the blown machine at each end of the beamline platform which move up and down with a speed of 0.05 mm/s bearing the 200 kg weight machine. Therefore, structure development and temperature changes as a function of position on the film bubble can be obtained. The blown film machine is customized to be conveniently installed with precise servo motors and can adjust the processing parameters in a wide range. Meanwhile, the air ring has been redesigned in order to track the structure information of the film bubble immediately after the melt being extruded out from the die exit. Polyethylene (PE) is selected as a model system to verify the feasibility of the apparatus and the in situ experimental techniques. Combining structure information provided by the WAXD and SAXS and the actual temperature obtained from the infrared probe, a full roadmap of structure development during film blowing is constructed and it is helpful to explore the molecular mechanism of structure evolution behind the film blowing processing, which is expected to lead to a better understanding of the physics in polymer processing.

Similar content being viewed by others

References

Zhang, X., Elkoun, S., Ajji, A. and Huneault, M., Polymer, 2004, 45(1): 217

Kanai, T. and Campbell, G.A., "Film processing", Carl Hanser Verlag GmbH Co KG, 2013, p. 3

Patel, R.M., Butler, T.I., Walton, K.L. and Knight, G., Polym. Eng. Sci., 1994, 34(19): 1506

Lu, J., Sue, H.J. and Rieker, T.P., J. Mater. Sci., 2000, 35(20): 5169

Field, G.J., Micic, P. and Bhattacharya, S.N., Polym. Int., 1999, 48(6): 461

Münstedt, H., Steffl, T. and Malmberg, A., Rheol. Acta, 2005, 45(1): 14

Kwack, T.H., Han, C.D. and Vickers, M., J. Appl. Polym. Sci., 1988, 35(2): 363

Choi, K.J., Spruiell, J.E. and White, J.L., J. Polym. Sci., 1982, 20(1): 27

Li, L., Wang, Q. and Wang, R., J. Appl. Polym. Sci., 2005, 98(2): 774

Lu, Y., Sun, Y.Y., Chen, R., Li, X.H. and Men, Y.F., Chinese J. Polym. Sci., 2014, 32(9): 1210

Hu, S., Rieger, J., Yi, Z., Zhang, J., Chen, X., Roth, S.V., Gehrke, R. and Men, Y.F., Langmuir, 2010, 26(16): 13216

Ajji, A., Zhang, X. and Elkoun, S., Polymer, 2005, 46(11): 3838

Ghaneh-Fard, A., Carreau, P. and Lafleur, P., Int. Polym. Proc., 1997, 12(2): 136

Gururajan, G. and Ogale, A.A., J. Raman Spectrosc., 2009, 40(2): 212

Bullwinkel, M., Campbell, G., Rasmussen, D., Krexa, J. and Brancewitz, C., Int. Polym. Proc., 2001, 16(1): 39

Aggarwal, S. and Tilley, G., J. Polym. Sci., 1955, 18(87): 17

Jdzefowiczt, M. and Epstein, A., Macromolecules, 1991, 24(3): 779

Heffelfinger, C. and Burton, R., J. Polym. Sci., 1960, 47(149): 289

Nikitenko, S., Beale, A.M., van der Eerden, A.M., Jacques, S.D., Leynaud, O., O–Brien, M.G., Detollenaere, D., Kaptein, R., Weckhuysen, B.M. and Bras, W., J. Synchrotron Radiat., 2008, 15(6): 632

Hughes, D., Mahendrasingam, A., Heeley, E., Oatway, W., Martin, C., Towns-Andrews, E. and Fuller, W., J. Synchrotron Radiat., 1996, 3(2): 84

Wang, Z., Ma, Z. and Li, L.B, Macromolecules, 2016, 49(5): 1505

Gururajan, G., Shan, H., Lickfield, G. and Ogale, A.A., Polym. Eng. Sci., 2008, 48(8): 1487

Gururajan, G. and Ogale, A.A., Polym. Eng. Sci., 2012, 52(7): 1532

van Drongelen, M., Cavallo, D., Balzano, L., Portale, G., Vittorias, I., Bras, W., Alfonso, G.C. and Peters, G.W., Macromol. Mater. Eng., 2014, 299(12): 1494

Troisi, E., van Drongelen, M., Caelers, H., Portale, G. and Peters, G., Eur. Polym. J., 2016, 74: 190

Meng, L.P., Lin, Y.F., Xu, J.L., Chen, X.W., Li, X.Y., Zhang, Q.L., Zhang, R., Tian, N. and Li, L.B., Chinese J. Polym. Sci., 2015, 33(5): 754

Cui, K.P, Liu, Y.P, Meng, L.P, Li, X.Y, Wang, Z., Chen, X.W. and Li, L.B, Polym. Test., 2014, 33: 40

Liu, Y.P, Zhou, W.M, Cui, K.P, Tian, N., Wang, X., Liu, L.B., Li, L.B. and Zhou, Y.G, Rev. Sci. Instrum., 2011, 82(4): 045104

Meng, L.P, Li, J., Cui, K.P, Chen, X.W, Lin, Y.F, Xu, J.L. and Li, L.B, Rev. Sci. Instrum., 2013, 84(11): 115104

Xu, H.J. and Zhao, Z.T, Nucl. Sci. Tech., 2008, 19(1): 1

Zeng, J.R, Bian, F.G, Wang, J., Li, X.H, Wang, Y.Z, Tian, F. and Zhou, P., J. Synchrotron Radiat., 2017, 24(2): 509

Butler, M.F. and Donald, A.M., J. Appl. Polym. Sci., 1998, 67(2): 321

Kuijk, E., Tas, P. and Neuteboom, P., J. Plast. Film Sheet, 1998, 14(2): 121

Chang, A., Tau, L., Hiltner, A. and Baer, E., Polymer, 2002, 43(18): 4923

Cherukupalli, S.S. and Ogale, A.A., Polym. Eng. Sci., 2004, 44(8): 1484

Stein, R.S. and Norris, F.H., J. Polym. Sci., 1956, 21(99): 381

Schultz, J., Lin, J. and Hendricks, R., J. Appl. Crystallogr., 1978, 11(5): 551

Hikosaka, M., Amano, K., Rastogi, S. and Keller, A., Macromolecules, 1997, 30(7): 2067

Calleja, F.B., Bassett, D. and Keller, A., Polymer, 1963, 4: 269

Charlier, P., 2012, U.S. Pat., 8,337,743

Author information

Authors and Affiliations

Corresponding authors

Additional information

This work was financially supported by the National Key R&D Plan of China (2016YFB0302501).

Rights and permissions

About this article

Cite this article

Zhang, R., Ji, Yx., Zhang, Ql. et al. A universal blown film apparatus for in situ X-ray measurements. Chin J Polym Sci 35, 1508–1516 (2017). https://doi.org/10.1007/s10118-017-2000-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10118-017-2000-z