Abstract

Radiation processing using electron beam (EB) has shown promising results in the treatment of organic water pollution. EB radiation is an additive-free process using short-lived reactive species, formed by the radiolysis of water, to carry out decomposition of organic pollutants. Studies have demonstrated the effectiveness of irradiation, alone or in combination with other processes, for the decomposition of refractory organic compounds in aqueous solutions, and in the removal or inactivation of microorganisms and parasites. Irradiation processes have been known for decades; however, their general application in the water field was impaired by the cumbersome and complexity of past existing technology. The technological picture is changing significantly in the last few years, with instrumentation that is significantly cheaper, easier and safer to use. Application of EB processing in the water sector promises a cost-efficient, by-products-less, and ultimately effective technology taking advantage of characteristics not available in others: total absence of chemical additives; capability of generating simultaneously both strong oxidants and reducers (hydroxyl radicals, hydrogen atoms, solvated electrons and others); capability of processing aqueous, colloidal, and opaque solutions; compatibility with existing technologies. This paper examines some of the few existing applications of this technology, which is still unknown, or poorly familiar, to most water professionals and researchers.

Similar content being viewed by others

Introduction

This review paper addresses an innovative, highly promising wastewater and water treatment solution: high-energy oxidation (HEO), implemented by electron beam irradiation, and aimed at tackling the pressing problem of organic micro-contaminants (including CECs, contaminants of emerging concern, EPA 2016) in natural, drinking waters, and wastewater discharges. Electron beam processing is a technology that induces water radiolysis that, in turn, causes strong oxidation and reduction reactions in the exposed solution, with the possible complete mineralization of the organic compounds therein contained. HEO processes, as they are indicated in this paper, were studied since the 1950s by radiation chemistry scientists (Kurucz et al. 1995), but never actually introduced into common water treatment practice, due to the cumbersome and expensive equipment then available. Current concerns with a series of newly detected emerging pollutants, difficult to remove with “conventional” treatment processes, may ultimately become a factor in bringing back into practice this technology, which has technically evolved in the meantime, due to a number of current, high-tech, ongoing applications in the most diverse industrial sectors. Multa renascentur quae iam cecidere (many things, which have fallen into disuse, will be reborn), a quote by Latin poet Horace (Horatius, about 65–68 B.C.), may best represent this situation, in which a technology, at one time considered efficient but impractical, is finally rediscovered due to newly arisen needs, and through better technical implementation. Still, full-scale applications are few, but as shown in this review paper, its potential is enormous.

The presence of metals, bacteria, hydrocarbons, and other ion-like nitrates (\({\text{NO}}_{3}^{ - }\)), ammonia (\({\text{NH}}_{4}^{ + }\)), and other “conventional” pollutants in water has been described for decades, as well as their impact on human health and the environment. Since these contaminants have been subject to regulation and control for a long time, effective technologies for their removal from wastewater are well established, and generally adopted (Callegari and Capodaglio 2017; Capodaglio and Callegari 2016; Capodaglio et al. 2015, 2016a). This is not the case for most emerging compounds, while it is a priority to remove them from drinking water, no effective removal technologies have been discovered, to date, which are capable to remove simultaneously all the contaminants of concern (Shi et al. 2012). Some techniques have demonstrated to remove, to a limited extent, certain contaminants: The most commonly used processes for this purpose are biodegradation and advanced oxidation processes (AOPs) (Shi et al. 2012; Capodaglio et al. 2010; Cecconet et al. 2017). Although partly effective, these processes may result in the formation of numerous degradation/transformation by-products, which are not well studied, as typical screening approaches for known compounds (typically, low resolution mass spectrometry utilizing triple quadrupole technology) are not yet capable of identifying them (Capodaglio et al. 2016b). Also, as biotransformation/biodegradation pathways are often not known (Wu et al. 2012), very few analytical standards are available for these secondary products (Helbling et al. 2010).

AOP treatment in aqueous media is also likely to be an expensive venture, since extremely high conversion yields are needed (ideally below detection limit), as these compounds retain their adverse properties even at minute concentrations, and have very low initial concentrations. These factors make the specific treatment cost (per unit mass) very high (Petrie et al. 2015).

Nanomaterials seem to have good potential for emerging contaminants removal, due to their large specific surface areas. However, to prevent their further spread into water, they will need subsequent immobilization onto macro-particles such as granular activated carbon (GAC), or powdered activated carbon (PAC). Recently, application of bioelectrochemical systems (BESs) for removal of small concentrations of pharmaceutical products from solutions was proposed (Pisciotta and Dolceamore 2016). BESs are a group of processes where electrochemical reactions are exploited for oxidative removal of environmental contaminants, associated with direct energy recovery (Capodaglio et al. 2013; Molognoni et al. 2014, 2015, 2017a), or through the use of small electric potentials, to achieve pollutants reductive removal (Molognoni et al. 2017b). Cecconet et al. (2017) recently reviewed the application of biological combination processes (e.g., membrane bioreactors combined with other technologies, such as BESs and others) to achieve improved pharmaceutical compounds removal from solutions. Research on new, efficient technologies for removal of emerging contaminants in waters will be top priority in the future years (Shi et al. 2012).

This review paper on HEO technology summarizes results of a few existing applications carried out so far in the water and wastewater field, illustrating potential advantages of the technology compared to current state-of-the-art AOP processes.

State-of-the-art CECs removal

State-of-the-art process technologies for CECs degradation include physicochemical treatments, oxidation by chlorination and/or ozonation, UV irradiation. Biodegradation is also applied, but can deliver mixed results, as not all these compounds can be completely broken down biologically, or happen to be bio-refractory. Even with best available technologies adopted, in fact, biological treatment may remove only part of the wide range of emerging contaminants. Estrogens, endocrine disruptors, and pharmaceuticals may appear in solution as ions, at neutral pH, and remain undegraded by biological treatment. Furthermore, they might not be adsorbed onto the activated sludge flocs, depending on their properties (Urase and Kikuta 2005). On the other hand, compounds or by-products accumulation into the solid (waste sludge) phase may contribute to transfer significant environmental risks to different media (e.g., soil), when sludge is disposed. Available advanced treatments include ultra-violet (UV) photolysis, ion exchange, and membrane filtration, often in combination with chemical oxidizers (e.g., O3, H2O2) and/or external catalysts addition (e.g., TiO2).

Among “conventional” processes present in state-of-the-art wastewater treatment facilities, physicochemical treatments such as coagulation–flocculation processes are generally found unable to obtain significant CECs removal (Bolong et al. 2009; Liu et al. 2009), except when used conjunctly with PAC or GAC dosage, oxidation by chlorination and/or ozonation, and/or UV irradiation (Westerhoff et al. 2005). Compounds such as carbadox, sulfadimethoxine, trimethoprim are not removed by metal salt coagulants (Adams et al. 2002), nor are diclofenac and carbamazepine (Petrovic et al. 2003; Vieno et al. 2006). PAC appears to be the most effective adsorbent material, especially for those substances containing refractory organics and non-biodegradable compounds (Abu-Zeid et al. 1995). The use of coagulants and PAC/GAC, however, introduces the need for proper downstream processing of the generated sludge, to avoid secondary spread of environmental contamination.

Oxidation is a promising removal mechanism for some compounds, especially when performed using strong oxidants, such as chlorine or ozone. Oxidation with these chemicals, however, has been shown to generate by-products, not yet fully studied, and whose effects are mostly unknown, save for a few. Ozone oxidizes substrates either directly, or by producing hydroxyl radicals that react with molecules in the solution. Both ozone and radicals are strongly reactive, and have been proposed by Huber et al. (2005) as promising options for the removal of CEC’s.

Wang et al. (2011) investigated AOPs removal efficiency of different pharmaceuticals (caffeine, acetaminophen, carbamazepine, sulfamethoxazole, trimethoprim, erythromycin, lincomycin, and codeine) as a function of treatment approach and type of disinfection (free chlorine, ozone, monochloramine, and permanganate). Oxidative removal of these compounds varied significantly: overall, chlorination was proven highly effective, but pH conditions caused notable differences in its efficiency. Permanganate was also effective to decompose some PPCPs.

Other advanced treatments tested for CECs removal include ultra-violet (UV) photolysis, ion exchange, and membrane filtration (Mboula et al. 2013): Bisphenol-A (BPA) conversion rates up to 99% were observed; this, however, corresponded to a mineralization ratio of just 40% (implying that the remaining 60% BPA was transformed into intermediate by-products of unknown characteristics). UV and ion-exchange addition may improve CEC’s removal, when applied conjunctly to other processes, but cannot be considered feasible stand-alone removal options, as they require absorbed doses about 100 times higher than those needed for disinfection, a result difficult to obtain in real conditions (Adams et al. 2002).

Combination of photocatalysis and chemical irradiation for CECs removal was attempted with success, however, also this required long reaction times, between 30 min and 8 h, depending on the treated compound. An extensive review on the use of AOPs for CEC (EDs and PPCPs) removal in water effluents was presented by Esplugas et al. (2007).

At the moment, the attention of researchers seems mostly focused on monitoring methodologies for these compounds, rather than finding generally applicable solutions for their elimination from water (Petrie et al. 2015). It should be pointed out that these compounds are usually present in water at trace levels (μg/L, or even ng/L); thus, most analytical instruments for their quantification require pre-concentration steps, such as solid phase extraction (SPE), solid phase microextraction (SPME), or accelerated solvent extraction (ASE). Detection methods must be developed accurately for each individual class of compounds and suffer severe limitations when they have to be applied for simultaneous pre-concentration of different contaminants (Bolong et al. 2009; Capodaglio 2017).

Shortcomings of current technologies

All the process technologies illustrated above have some, more or less significant, drawbacks: almost all require extended contact times for removal or destruction of contaminants to occur (in the order of few to several hours, to achieve transformations up to about 90% of the original contaminants’ mass). Furthermore, even when such transformations occur, they do not necessarily lead to full mineralization of contaminants, as oxidation of these chemicals has often been found to generate by-products, with mostly unknown effects, which may also be as harmful as the original compounds, or more (Huerta-Fontela et al. 2011). These compounds may be found in treated water effluents or in process residuals (e.g., in biological or chemical sludges) with considerable risk of secondary dispersion in the environment.

Destruction of CECs by application of the indicated technologies has shown to be heavily dependent on environmental and process conditions, with possible cross-interference among various factors. Since most of these processes require additives (PAC, nanomaterials, catalysts), these may constitute significant additional process cost factors. Costs may be in the form of process coadjuvants, or in the generation of additional process residues (e.g., spent PAC and nanoparticles, process sludges) that should be properly disposed of. Additionally, when strong oxidants are used, process and operator’s safety is always an issue. Certain additives, either by improper use or by accident, could themselves cause generation of new pollutants (i.e., disinfection by-products (DBPs), when using chlorine), precursors of carcinogenic compounds, or induce undesired contamination if released into the environment (Bolong et al. 2009; Liu et al. 2009; Chang et al. 2009).

Rationale for high-energy oxidation processes

Radiation processing with high-energy electron accelerators (a.k.a. Electron Beam, EB processing) has shown very promising results in most diverse application areas: from optimization and improvement of industrial productions (packaging films, insulation of submarine data cables, medical hydrogels and lubricants), to processing of surface coatings and adhesives, grafting of new materials, sterilization of pharmaceuticals and disposable medical devices, food distribution and safety (irradiation of fruits and vegetables, chilled meats and fish for optimized, additive-free storage, and of agricultural seeds for improved conservation), to flue gas emission and contaminated soils treatments (IAEA 2008).

In all these fields, EB technology is routinely used today, in total safety and with proof of no subsequent issues of environmental radiation contamination. The technological progress achieved in these fields has brought the technology to a maturity level economically compatible with many new, diverse applications. Studies on EB application to the water sector can in fact be dated back to the 1950s, supported by positive results, but impaired in their general, wider sectorial application by a then awkward, difficult-to-operate technology. Today, based on modern applications and new studies, promising results obtained in the treatment of emerging pollutants and ED’s in laboratory tests, and on the general industrial improvement of this technology, HEOs application in the water field offers a promise of cost effectiveness and efficiency (IAEA 2014).

EB technology

EB irradiation is a process involving the use of electrons charged with high energy (hence the alternative term of High-Energy Oxidation), to treat an object, or medium, for a variety of purposes, including modification (as in industrial applications) or destruction (environmental applications) of undesired molecules, or intermolecular links. The basic components of a typical electron beam device are schematized in Fig. 1: in a sealed device kept under high vacuum, a heated emitter (cathode) releases electrons that are then accelerated by a grid, using high voltage–power supply (DC) or radiofrequency (in more compact designs). Electrostatic and/or magnetic fields control beam direction (by focusing and deflection) on an exit window, cut on thin metal foil. Electrons emerge from the window with energy proportional to the high voltage applied to the anode, in quantity depending on cathodic current. By adjusting these parameters, it is possible to control, respectively, penetration of the beam (proportional to energy) and dose rate (proportional to current). The entire apparatus is conceptually very similar (except for the amount of energy involved) to an old-fashioned cathodic-tube television box.

The energy emitted by an EB machine is measured in electronvolt (eV), which by definition is the amount of energy gained (or lost) by the charge of a single electron moving across an electric potential difference of 1 V. One electronvolt is equal to approximately 1.602 × 10−19 J (a very small quantity), therefore the KeV (103 eV) is commonly used as reference unit. EB machines used in the water and wastewater treatment field are usually rated between 500 keV and 1.2 MeV, but some can also reach 10 MeV. The irradiation dose is measured in Grey (Gy), defined as the absorption of one joule of radiation energy by one kilogram of matter. As a reference number, a dose of 1.5 KGy, such as those commonly used to achieve wastewater disinfection, is a relatively low value, in the low range of those adopted, for example, in food distribution industry applications (irradiation of fresh vegetables for fungi and bacteria control, in order to increase product shelf life). The use of direct high voltage to produce the beam allows the conversion of input AC power to beam power with an efficiency greater than 95%, thus making EB irradiation a highly energy-efficient process. By comparison, modern UV systems commonly applied in wastewater disinfection have energy efficiencies (conversion of electric energy to UV) of about 30%, at best.

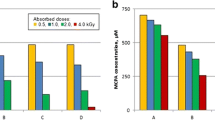

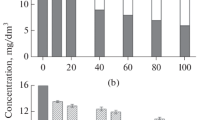

In traditional industrial applications, the effect of irradiation causes degradation of target molecules, breaking their internal chains and therefore reducing their molecular weight. Controlled molecular transformations can modify the intrinsic properties of irradiated materials, improving them (e.g., resistance of rubber coating of submarine data cables, or creation of materials with novel properties). In water-related applications, EB irradiation takes advantage of special characteristics not available in most other treatment technologies: capability of generating simultaneously both strong oxidants and reducers in the solution (superoxides, a.k.a. hyperoxides, \({\text{O}}_{2}^{ - }\), hydroxyl radicals, ·HO, hydrogen atoms, H, and solvated electrons, \({\text{e}}_{{({\text{aq}})}}^{ - }\)), absence of the need for chemical additives. The generated species are very reactive, extremely short-lived, with half-lives in the order of 10 μs at 10−4 M concentration (Fig. 2), and much stronger oxidation potentials than O3 (Table 1). They are thus capable of carrying out degradation of pollutants, potentially until complete mineralization, or to a desired degree of decomposition, according to absorbed dose and intensity of irradiation (Fig. 3).

Oxidation potential values for different oxidant species are reported in Table 1. Reactions occurring under EB irradiation are in reality quite similar to those occurring in AOPs, where oxidation is largely brought about by OH-radicals, but with much greater intensity due to greater density and assortment of radical species. Reactions are similar to those discovered in 1894 by the British chemist Henry Fenton, who described the strong oxidizing activity of a mixture of H2O2 and \({\text{Fe}}_{2}^{ + }\) (a.k.a. Fenton’s reagent). About 40 years later, the active species in Fenton’s reaction was shown to be ·HO.

The combination of EB with other processes is also possible. For example, chemicals (O3, hydrogen peroxide, TiO2, etc.) can be added to increase the efficiency of reactions, by increasing the specific amount of radicals generated by radiolysis. Solution pre-irradiation, at low dose, can be combined with biological processes to improve biodegradability of refractory compounds: such a combined treatment train could remove more efficiently many organic contaminants. The degree of compound degradation can be easily controlled by the irradiation dose-rate, however, complete organic compound mineralization, although achievable, is not always the ultimate objective of these processes, as it could be more cost-efficient to achieve partial degradation by irradiation, concluding the removal process by other means, as illustrated in “Application examples of EB irradiation in water and wastewater treatment” section.

In summary, EB irradiation processing are an additive-free, residual-free and, potentially, by-products-free, flexible technology that uses short-lived, reactive species formed during radiolysis of water for an efficient decomposition of pollutants. For practical purposes, therefore, these processes can be considered as highly innovative, alternative AOP’s with few of the potential shortcomings related to the latter.

EB process kinetics

In a diluted, irradiated aqueous solution, practically all of the energy absorbed is used in the process of water radiolysis, without affecting the radioactivity of the solution itself. The main products of irradiation are both strongly oxidizing, such as hydroxyl radicals (·OH), and strongly reducing species, like solvated electrons (\({\text{e}}_{\text{aq}}^{ - }\)), hydrogen radicals (·H), in addition to other, less reactive, species, such as H2, H2O2 and H3O+. Reaction rate constants of ·OH-radicals with many organic species are about 109 times higher than those of O3 in pure solutions, as reported by Buxton et al. (1987). While hundreds of studies exist on the kinetics of radiolytic decomposition of various groups of environmental pollutants, these were carried out mostly on single-component, synthetic solutions. In real conditions (wastewater/natural water with complex matrix), some compounds naturally present in solution could themselves act as radicals scavengers (e.g., O2, \({\text{HCO}}_{3}^{ - }\), \({\text{CO}}_{3}^{2 - }\), Cl−, \({\text{NO}}_{2}^{ - }\), \({\text{NO}}_{3}^{ - }\), DOC), decreasing overall process efficiency. To increase the intensity of radiolytic decomposition of target compounds, the process can be carried out in the presence of externally added N2O, which is known to interact with radiolysis products, generating additional amounts of hydroxyl radicals through fast reactions with both \({\text{e}}_{\text{aq}}^{ - }\) and ·H.

All the radical species react with target pollutants depending on the structure and properties of the latter; their removal yield is different for different compounds, as shown by values reported in literature (Cooper et al. 2002; Buxton et al. 1987). From these, kinetic models directly applicable to pure, monocomponent solutions can be derived. Knowledge of individual reaction rate constants can be employed for preliminary radiolytic decomposition modeling, including determination of decomposition yields as a function of initial solute concentration, pH, and operational conditions. As a result of all the mentioned interfering phenomena, however, pollutants decomposition kinetics in real conditions may significantly differ from those evaluated theoretically through literature-reported coefficients for pure, monocomponent solutions. Practically, all these effects can be currently determined only experimentally. Application of radiolysis as a treatment process should not be based solely on approximate yield calculations, but should be empirically tested, at least in the most complex situations. The same considerations, however, are true for most other AOP processes currently applied.

Application examples of EB irradiation in water and wastewater treatment

Various application examples of HEO, related to some major groups of pollutants or most relevant issues in water and wastewater treatment, are reported herein. This section also includes some of the latest results reported from last year’s published literature, as an indication to the fact that this technology is realistically pursued by small groups of researchers on very specific water contamination issues. The most recent studies published on EB treatment of water and wastewaterFootnote 1 concern mainly industrial wastewaters (textile, metal works) and pharmaceuticals’ contamination, and prove that, although still at a small scale, the interest in this specific technology is very much alive.

Endocrine disruptors and pharmaceutical substances

Radiation processing of WWTP effluents has shown that destruction of organic compounds, elimination of estrogenic activity, and efficient disinfection can occur simultaneously. EB processes were shown to be very efficient at removing even extremely low concentrations of estrogens (Gehringer et al. 2008; Ahn and Jung 2013). Demonstration studies on the decomposition of antibiotics and EDs, were carried out with a mobile, 600 keV electron accelerator built by the Korean Atomic Energy Research Institute (KAERI). These involved a synthetic solution containing lincomycin, tetracycline and bisphenol-A at final concentration of 0.5 mg/l (each). The mixture, subject to irradiation by creating a thin flow blade under the EB, with velocity of about 3 m/s, absorbed dose of 1.5 kGy, and average beam current of 20 mA achieved compounds degradation in about 1/100th of a second, with lincomycin removal = 99.8%, tetracycline’s = 98.8%, and Bisphenol-A = 99.1%. In addition, sterilization of 98.3% of the microorganisms (coliforms) present in the wastewater, and an approximately tenfold toxicity reduction (from 15 to just 1.8 TU after irradiation) were observed (Lee et al. 2012).

A recent study on removal from water of persistent pharmaceuticals by EB irradiation showed that full mineralization dose could be calculated fairly precisely by competition reaction method (Kimura et al. 2012). Furthermore, Kimura et al. (2007) had previously shown that removal of endocrine disrupting chemicals from wastewater could be achieved at the very low absorbed dose of 200 Gy, at an estimated cost of US$ 0.17/m3 of treated water. It was also shown that addition of TiO2 prior to water irradiation improved degradation efficiency of pesticides (Emmi et al. 2008; Trojanowicz et al. 2008; Şolpan 2008a, b). Application to wastewater effluent from a mixed municipal/industrial facility in Austria showed that EB irradiation, at 2 kGy dose, was sufficient to reduce by two orders of magnitude the concentrations of all naphthalene sulfonic acids, and of part of the alkylphenol ethoxylates. At the same time, irradiation also effectively inactivated indicator bacteria, and simultaneously eliminated all estrogenic activity from natural and synthetic hormones contained in the effluent (Gehringer et al. 2008).

Sulfamethoxazole (SMX), a widely used sulfonamide antibiotic with frequent environmental presence, is highly resistant to biological degradation; hence, AOPs are usually applied to its removal from solution (Lester et al. 2010). Studies also attempted to assess simultaneously the changes of biodegradability, and the inhibitory effects of by-products formed during its treatment. Sagi et al. (2016) studied changes in biological degradability during SMX treatment by ionizing radiation, while investigating the inhibitory effects of its degradation products on the biological community of a municipal activated sludge plant. Degradation of SMX by EB showed to be linearly dependent on irradiation dose and pollutant initial concentration, halving its value at 0.4 kGy absorbed dose, and disappearing in solutions treated with doses >1.5 kGy. With prolonged irradiation, BOD5 increased, indicating conversion of non-biodegradable SMX to biologically treatable substances. At a 2.5 kGy dose, the BOD5/COD ratio increased to 0.16, while TOC showed a decrease of 15%, indicating that high degrees of mineralization are not always necessary to make a compound available to biodegradation.

Water disinfection

HEOs have proven highly efficient in water and wastewater disinfection. In several studies, inactivation efficiency of bacteria and spores by EB was found to be practically unaffected by water matrix characteristics and suspended solids concentrations, an obvious advantage over traditional AOP processes, affected by high turbidity. Strong indications from literature also suggest that these findings are relevant to some viruses of concern (like poliovirus) in water (Gehringer et al. 2008). Disinfection of microbiologically contaminated drinking water supplies in Jordan by EB processing was shown to be an extremely efficient treatment: an irradiation dose of 1 kGy was optimal for control of the microbiological load of raw drinking water, containing up to 1000 E. coli per 100 mL. Irradiation doses around 1.5 kGy were found efficient in controlling microbiological content of domestic WWTP effluents, in order to meet reuse requirements in unrestricted irrigation, and doses of 2 kGy were recommended to ensure avoidance of microbiological re-growth after irradiation. Irradiation was shown effective in the deactivation of nematode eggs, with deactivation success of 96% at a dose of 5 kGy. In all cases, the irradiation dose required for microbiological disinfection depended solely on the microbiological load of the water: physical parameters, such as TSS and turbidity, usually affecting traditional processes significantly, and seasonal variations between summer and winter periods had only minor effects on the operational efficiency of the process (Amro et al. 2008).

Drinking water

Trihalomethanes (THMs) are chemical compounds in which three of the four hydrogen atoms of methane (CH4) are replaced by halogens. Many trihalomethanes are used in industry as solvents or refrigerants, and are considered environmental pollutants, with many of them also considered carcinogenic. Trihalomethanes are also formed as a by-product of water disinfection, predominantly when chlorine is used, representing a group of chemicals generally referred to as disinfection by-products (DBPs). Studies have shown that more than 98% of THMs in drinking water supplies, up to concentrations of 100 μg/L could be removed with EB treatment by applying an irradiation dose of 1 kGy. To control THM reformation in drinking water supply networks, higher doses up to 10 kGy could be necessary, to remove all precursors from irradiated waters (Amro et al. 2008). A substantial advantage of EB irradiation for drinking water disinfection is that it would completely eliminate the possibility of DBP formation and guarantee inactivation of microorganisms (Han et al. 2008).

Wang et al. (2016) recently investigated EB as a method for removing bromate and perfluorooctanoic acid (PFOA) from treated wastewater intended for potable reuse. Bromate is also a disinfection by-product (DBP) formed when bromide-containing waters (as a result of geological dissolution, brackish water intrusion, or human activities) are treated with ozone. Bromate has been shown to be carcinogenic in rat kidneys, and to be rapidly absorbed from the gastrointestinal tract, causing gastrointestinal symptoms, in humans. EB treatment at a dose of 1 kGy was sufficient to remove 70% of bromate from an initial concentration of 100 μg/L in NOM-free water.

Perfluorooctanoic acid (PFOA), detected in various locations globally, is one of the most abundant perfluorinated chemicals (PFCs) in the environment. It has tested positive to increased tumor incidents in experimental rats and is associated with reduced birth weight when pregnant women are exposed to it. PFOA is very stable and there is no evidence showing that it can be naturally degraded. AOPs studies indicated that hydroxyl radicals could not successfully decompose PFOA due to the electronegativity of its fluoride atoms. A study on irradiation treatment by γ-ray from a 60Co source achieved complete mineralization of PFOA in a N2-saturated condition at pH 13. Further studies showed that EB was effective in removing \({\text{BrO}}_{3}^{ - }\) and defluorinating PFOA in the absence of oxygen. Degradation of these oxidized compounds is probably the result of reaction with reducing radicals (\({\text{e}}_{\text{aq}}^{ - }\) and H) that are produced during water radiolysis. The more complex behavior of PFOAs indicates that other radicals such as ·OH and \({ \cdot }{\text{CO}}_{3}^{ - }\) could also be important in its degradation.

Textile wastewaters

A pilot plant for treating 1000 m3/d of textile dying wastewater with EB irradiation was constructed and continuously operated since October 1998, in South Korea. The facility, combining irradiation with biological treatment, showed reduction of chemical additives consumption, reduction in process retention time, and increase in removal efficiency of COD, compared with the preexisting solution. Following these tests, a full-scale industrial plant was completed in Daegu in December 2005, with a capacity of 10,000 m3/day. The facility used a 1 MeV, 400 kW accelerator combined with the existing bio-treatment facility (Han et al. 2008). HEO was also applied to induce degradation of different bio-recalcitrant textile dyes in wastewater, such as Apollofix-Red (AR-28), Reactive Black 5, H-acid, (4-amino-5-hydroxynaphthalene-2,7-disulfonic acid, I) and its derivative, 4-hydroxynaphthalene-2,7-disulfonic acid (Takács et al. 2008).

Borrely et al. (2016) tested decoloration and detoxification of real textile effluents by ionizing radiation in batch mode. Results highlighted that for two textile effluent samples, a relatively low absorbed dose of 2.5 kGy was effective for effluents decoloration and detoxification. The same dose, however, was not sufficient for treatment of samples from a chemical industry to the same degree, even though it reduced acute toxicity effects for all of them. Results also demonstrated that, since irradiation was applied before the biological treatment step, the latter showed substantial advantages from the reduced toxicity and improved treatability of the influent.

Other industrial wastes and pesticides

Experimental results indicate that radiolytic degradation may be a suitable and effective method for treatment of industrial wastes and pesticides (2,4-D, MCPA, carbendazim, etc.) and that kinetic modeling, based on rate constants of radical reactions involved, can sometimes predict with good or satisfactory agreement such results, proving that the process could also be reliably designed from a theoretic basis (Trojanowicz et al. 2008).

Inorganic wastes and other contaminants

Recently, it was shown that EB irradiation of both synthetic and real industrial effluents can result in removal of numerous inorganic components, including heavy metal ions (Ribeiro et al. 2004). Although this requires rather high absorbed doses (20 kGy), more than 96% of Cr, Fe, Zn and Co were reduced to insoluble forms, from original g/L concentration levels in the solution. Cadmium seems less susceptible to precipitation by this process, as well as other metals. Removal of Cadmium, Lead (Guo et al. 2008a, b) and nitrates (Guo et al. 2008a) from solutions by irradiation were also reported.

Waste metalworking fluids (WMFs) are representative of waste streams that are heavily polluted, toxic, recalcitrant to bio-treatment, and require more sustainable routes of safe disposal. Traditionally, spent WMFs are treated chemically or by evaporation or ultrafiltration, but advances showed that their biological treatment may be a promising cost- and energy-effective option, in particular if combined with advanced oxidation processes (AOPs) such as Fenton’s reagent, or other hybrid approaches that include biodegradation, electron beam irradiation, and zero-valent nano-iron AOPs, employed individually, or in sequence (Thill et al. 2016). Treatment of MWF with EB showed initially no detectable impact on COD removal, however, acute toxicity decreased with increasing absorbed dose, indicating transformation of organic molecules into biodegradable ones. Biological, nano-iron and EB treatment were tested in sequential combinations and permutations to identify the optimum hybrid treatment sequence. The sequence that lead to optimal synergistic detoxification was found to be EB, biological, nanoscale zero-valent iron and an additional biological phase, in that order. Overall COD removal for pristine MWF improved by 92.8 ± 1.4%, a significantly greater value than with biological treatment on its own. EB pretreatment enabled these waste streams to be biotreated at high concentrations, confirming that, even when employed as a complementary treatment, the feasibility of EB treatment is a realistic and potentially economic option for treating recalcitrant wastewaters.

Discussion

Pollutant removal processes in water and wastewater treatment facilities have been undergoing significant development in the last years due to concerns about new, difficult-to-remove classes of contaminants. Among “innovative” processes, AOPs, mostly based on the reactivity properties of hydroxyl radicals ·OH are a very active research topic today. Strangely enough, one of the most efficient ways for the production of such radicals, water radiolysis by means of ionizing radiation, is often not even mentioned in extensive and comprehensive reviews of the field (Gligorovski et al. 2015), nor is much known or diffused in current practice. HEO for water and wastewater treatment, currently well known almost only to radiation chemists, could be an innovative “Columbus’ Egg” Footnote 2 solution to many emerging problems in the field, known, or yet to be discovered, that could ensure consistent and reliable results that other solutions struggle to deliver. The main advantages of EB processes, discussed in this review, consist of an ample degradation range potential of organic and inorganic contaminants, related to the absorbed energy–dose, and not to reaction time (which is practically instantaneous). Absence of additives, residuals and by-products, the almost total control that can be exerted on the process and its end-points by varying applied energy and adsorbed dose (depending on the desired degree of solutes degradation), and easy energy deliver with a high degree of precision by easy-to-operate facilities are among the advantages of this technology (Table 2).

Although complete mineralization of organic compounds is possible (at appropriate irradiation and adsorption doses), another advantage of this technology is that it can be used in a highly controlled fashion, and thus combined with other types of more traditional treatment processes, if appropriate and economically convenient, as illustrated in the previous section. For example, in the case of refractory, poorly degradable organic compounds, the process can be used as a pre-treatment to break down large “indigestible” molecules to more biodegradable ones. Despite its extended possibilities, it probably would not be economically appropriate to use EB to completely mineralize easily biodegradable organic matter, but its use may be economically advantageous in dealing with other types of complex organics contamination, or to obtain DBPs-free disinfection, and elimination of antibiotic resistant bacteria, a considerable current concern (Amro et al. 2008; Gehringer et al. 2008; Han et al. 2008; Sungpyo and Aga 2007).

The cost of implementation of a technology strongly underlies almost all of the decision-making in its selection for application. In many cases, the only existing economic analyses for new technologies derive from small-scale, laboratory-level applications, as is in the case of the presented technology. Given the type of technology, its economic feasibility improves with increasing size of electron accelerator apparatus (Table 3), as its unit cost decreases exponentially with installed beam power. Of course, full-scale research in industrial pilot plants should result in a better knowledge of actual costs: Table 3 summarizes literature-reported cases in which costs of processes, including a HEO step, have been reliably estimated, reported in descending date of implementation. Although it is difficult to extrapolate the mere cost of the HEO step from the reported examples (they expose the total cost of processing), overall treatment costs exposed in the Table seem for the most part to be in line with the general costs of specific treatments at that time.

In addition to some residual uncertainty about actual costs of the technology, factors that hindered diffusion of this technology in the water sector in the past, like large, un-friendly and expensive equipment have been already partly solved by technological progress due to increasing numbers of applications in other sectors. Some limiting factors at the moment are: the scarcity of real application examples, as the technology is mainly applied demonstratively by few researchers at small scale; poor, or still not fully convincing, dissemination to water professionals and, not least, the fear of public reaction in case of adoption of an “irradiation-branded” technology, that may evoke in laymen nuclear-type scenario.

Conclusions

EB treatment of water and wastewater has been largely overlooked or ignored so far by the sectoral technology; however, it may play an important role in future treatment schemes for emerging compounds, or in other specific instances, especially if the cost of irradiation equipment continues to decrease due to greater diffusion into other productive sectors.

Notes

All references related to pollutants degradation in pure solutions have been neglected here. Although available in much larger numbers (hundreds), they do not directly reflect the need and interest for practical application of this technology in wastewater matrices.

This is a term sometimes used when a brilliant idea that seems simple or easy after the fact is applied to an apparently insoluble problem. Legend traces the term to an unconfirmed anecdote from the life of explorer Christopher Columbus.

References

Abu-Zeid N, Nakhla G, Farooq S, Osei-Twum E (1995) Activated carbon adsorption in oxidizing environment. Water Res 29:653–660

Adams C, Wang Y, Loftin K, Meyer M (2002) Removal of antibiotics from surface and distilled water in conventional water treatment process. J Environ Eng 128:253–260

Ahn BY, Jung J (2013) Reduction of estrogenic activity of wastewater effluents by radiation treatment. Research report, division of environmental science and ecological engineering. Korea University, Seoul

Amro H, Tuffaha R, Zenati S, Jneidi M (2008) Remediation of polluted waters and wastewater by irradiation processing in Jordan. In: Radiation treatment of polluted water and wastewater, industrial applications in chemistry, report IAEA-TECDOC-1598. International Atomic Energy Agency, Vienna

Bolong N, Ismail AF, Salim MR, Matsuura T (2009) A review of the effects of emerging contaminants in wastewater and options for their removal. Desalination 239:229–246

Borrely SI, Morais AV, Ros JM, Badaro-Perdroso X, Pereira MC, Higa MC (2016) Decoloration and detoxification of effluents by ionizing radiation. Radiat Phys Chem 124:198–202

Buxton GV, Greenstock CL, Helman WP, Ross AB (1987) Critical review of rate constants for reaction of hydrated electrons, hydrogen atoms and hydroxyl radical (·OH/·O−) in aqueous solution. J Phys Chem Ref Data 17:512–887

Callegari A, Capodaglio AG (2017) Effects of selected industrial pollutants on urban WWTPs activated sludge population, and possible mitigation strategies. Water Pract Technol. doi:10.2166/wpt.2017.064

Capodaglio AG (2017) In-stream detection of waterborne priority pollutants, and applications in drinking water contaminant warning systems. Water Sci Technol Water Supply 17(3):707–725. doi:10.2166/ws.2016.168

Capodaglio AG, Callegari A (2016) Domestic wastewater treatment with a decentralized, simple technology biomass concentrator reactor. J Water Sanit Hyg Dev 6(3):507–510. doi:10.2166/washdev.2016.042

Capodaglio AG, Suidan M, Venosa AD, Callegari A (2010) Efficient degradation of MtBE and other gasoline-originated compounds by means of a biological reactor of novel conception: two case studies in Italy and in the USA. Water Sci Technol 61(3):807–812

Capodaglio AG, Molognoni D, Dallago E, Liberale A, Cella R, Longoni P, Pantaleoni L (2013) Microbial fuel cells for direct electrical energy recovery from urban wastewaters. Sci World J 3:1–8

Capodaglio AG, Hlavínek P, Raboni M (2015) Physico-chemical technologies for nitrogen removal from wastewaters: a review. Revista Ambiente Água 10(3):481–498. doi:10.4136/ambi-agua.1618

Capodaglio AG, Callegari A, Molognoni D (2016a) Online monitoring of priority and dangerous pollutants in natural and urban waters: a state-of-the-art review. Manag Environ Qual 27(5):507–536

Capodaglio AG, Hlavínek P, Raboni M (2016b) Advances in wastewater nitrogen removal by biological processes: state of the art review. Ambiente Água Interdiscip J Appl Sci 11(2):250–267

Cecconet D, Molognoni D, Callegari A, Capodaglio AG (2017) Biological combination processes for efficient removal of pharmaceutically active compounds from wastewater: a review and future perspectives. J Environ Chem Eng 2017(5):3590–3603

Chang HS, Choo KH, Lee B, Choi J (2009) The methods of identification, analysis, and removal of endocrine disrupting compounds (EDCs) in water. J Hazard Mater 172:1–12

Cooper WJ, Nickelsen MG, Mezyk SP, Leslie G, Tornatore PM, Hardison W, Hajali PA (2002) MTBE and priority contaminant treatment with high energy electron beam injection. Radiat Phys Chem 65:451–460

Emmi SS, De Paoli G, Takács E, Caminati S, Pálfi T (2008) The E-beam induced decomposition of pesticides in water: a gamma and pulse radiolysis investigation on carbofuran. In: radiation treatment of polluted water and wastewater. Industrial applications in chemistry, report IAEA-TECDOC-1598. International Atomic Energy Agency, Vienna

EPA (2016) Contaminants of emerging concern including pharmaceuticals and personal care products. US EPA website. https://www.epa.gov/wqc/contaminants-emerging-concern-including-pharmaceuticals-and-personal-care-products. Accessed May 2016)

Esplugas S, Bila DM, Krause LGT, Dezotti M (2007) Ozonation and advanced oxidation technologies to remove endocrine disrupting chemicals (EDCs) and pharmaceuticals and personal care products (PPCPs) in water effluents. J Hazard Mater 149:631–642

Gehringer P, Fiedler H (1998) Design of a combined ozone/electron beam process for waste water and economic feasibility of the process. Radiat Phys Chem 32:345–349

Gehringer P, Eschweiler H, Weiss S, Reemtsma T (2008) Effluent polishing by means of advanced oxidation. In: Radiation treatment of polluted water and wastewater. Industrial applications in chemistry, report IAEA-TECDOC-1598. International Atomic Energy Agency, Vienna

Gligorovski S, Strekovski R, Barbati S, Vione D (2015) Environmental implications of hydroxyl radicals (·OH). Chem Rev 115:13051–13092

Guo Z, Tang D, Liu X, Zheng Z (2008a) Gamma irradiation-induced Cd2+ and Pb2+ removal from different kinds of water. Radiat Phys Chem 77:1021–1026

Guo Z, Zheng Z, Gu C, Zheng Y (2008b) Gamma irradiation-induced removal of low-concentration nitrite in aqueous solution. Radiat Phys Chem 77:702–707

Han B, Kim JK, Kim YR (2008) Disinfection of effluent from municipal wastewater plant with electron beam. In: Radiation treatment of polluted water and wastewater. Industrial applications in chemistry, report IAEA-TECDOC-1598. International Atomic Energy Agency, Vienna

Helbling DE, Hollender J, Kohler HPE, Singer H, Fenner K (2010) High-throughput identification of microbial transformation products of organic micropollutants. Environ Sci Technol 44:6621–6627

Huber MM, Gobel A, Joss A, Hermann N, Loffler D, Mcardell AR, Siegrist H, Ternes TA, Gunten U (2005) Oxidation of pharmaceuticals during ozonation of municipal wastewater effluents: a pilot study. Environ Sci Technol 39:4290–4299

Huerta-Fontela M, Galceran MT, Ventura F (2011) Occurrence and removal of pharmaceuticals and hormones through drinking water treatment. Water Res 45:1432–1442

IAEA (2008) Radiation treatment of polluted water and wastewater. Industrial applications in chemistry, report IAEA-TECDOC-1598, International Atomic Energy Agency. Vienna

IAEA (2014) Nuclear technology review. International Atomic Energy Agency, Vienna

Kimura A, Taguchi M, Ohtani Y, Shimada Y, Hiratsuka H, Kojima T (2007) Treatment of wastewater having estrogen activity by ionizing radiation. Radiat Phys Chem 76:699–706

Kimura A, Osawa M, Taguchi M (2012) Decomposition of persistent pharmaceuticals in wastewater by ionizing radiation. Radiat Phys Chem 81:1508–1512

Kuk SH, Kim SM, Kang WG, Han B (2011) High-power accelerator for environmental applications. J Kor Phys Soc 59:3485–3488

Kurucz CN, Waite TD, Cooper WJ (1995) The Miami electron beam research facility: a large scale wastewater treatment application. Radiat Phys Chem 45:299–308

Lee MJ, Kim TH, Jung IH (2012) A demonstration study on decomposition of antibiotics and endocrine disrupters contained in sewage effluent by mobile electron beam accelerator. In: Proceedings, 2nd research coordination meeting on radiation treatment of wastewater for reuse with particular on wastewaters containing organic pollutants. International Atomic Energy Agency, Division of Physical and Chemical Sciences, Vienna, pp 103–110

Lester Y, Avisar D, Mamane H (2010) Photodegradation of the antibiotic sulphamethoxazole in water with UV/H2O2 advanced oxidation process. Environ Technol 31:175–183

Liu Z, Kanjo Y, Mizutani S (2009) Removal mechanisms for endocrine disrupting compounds (EDCs) in wastewater treatment—physical means, biodegradation, and chemical advanced oxidation: a review. Sci Total Environ 407:731–748

Mboula VM, Hequet V, Andres Y, Pastrana-Martınez LM, Dona-Rodrıguez JM, Silva AMT, Falaras P (2013) Photocatalytic degradation of endocrine disruptor compounds under simulated solar light. Water Res 47:3997–4005

Molognoni D, Puig S, Balaguer MD, Liberale A, Capodaglio AG, Callegari A, Colprim J (2014) Reducing start-up time and minimizing energy losses of microbial fuel cells using maximum power point tracking strategy. J Power Sources 269:403–411

Molognoni D, Puig S, Balaguer MD, Capodaglio AG, Callegari A, Colprim J (2015) Multiparametric control for enhanced biofilm selection in microbial fuel cells. J Chem Technol Biotechnol 91(6):1720–1727. doi:10.1002/jctb.4760

Molognoni D, Chiarolla S, Cecconet D, Callegari A, Capodaglio AG (2017a) Industrial wastewater treatment with a bioelectrochemical process: assessment of depuration efficiency and energy production. Water Sci Technol

Molognoni D, Devecseri M, Cecconet D, Capodaglio AG (2017b) Cathodic groundwater denitrification with a bioelectrochemical system. J Water Process Eng 19:67–73

Petrie B, Barden R, Kasprzyk-Hordern B (2015) A review on emerging contaminants in wastewaters and the environment: current knowledge, understudied areas and recommendations for future monitoring. Water Res 72:3–27

Petrovic M, Diaz A, Ventura F, Barcelo D (2003) Occurrence and removal of estrogenic short chain ethoxy nonylphenolic compound and their halogenated derivatives during drinking water production. Environ Sci Technol 27:4442–4448

Pisciotta JM, Dolceamore JJ (2016) Bioelectrochemical and conventional bioremediation of environmental pollutants. J Microb Biochem Technol 8:327–343

Ribeiro MA, Sato IM, Duarte CL, Sampa MHO, Salvador VLR, Scapin MA (2004) Application of the electron-beam treatment for Ca, Si, P, Al, Fe, Cr, Zn Co, As, Se, Cd and Hg removal in the simulated and actual industrial effluents. Radiat Phys Chem 71:423–426

Sagi G, Kovacs K, Bersenyi A, Csay T, Takacs E, Wojanrovits L (2016) Enhancing the biological degradability of sulfamethoxazole by ionizing radiation treatment in aqueous solution. Radiat Phys Chem 124:179–183

Shi H, Cheng X, Wu Q, Mu R, Ma Y (2012) Assessment and removal of emerging water contaminants. J Environ Anal Toxicol S2:003. doi:10.4172/2161-0525.S2-003

Shin H, Kim Y, Han B, Makarov IE, Ponomarev AV, Pikaev AK (2002) Application of electron beam to treatment of wastewater from papermill. Radiat Phys Chem 65:539–547

Şolpan D (2008a) Decoloration and degradation of some textile dyes by gamma-irradiation. In: Radiation treatment of polluted water and wastewater. Industrial applications in chemistry, report IAEA-TECDOC-1598. International Atomic Energy Agency, Vienna

Şolpan D (2008b) The degradation of some pesticides in aqueous solutions by gamma radiation. In: Radiation treatment of polluted water and wastewater. Industrial application in chemistry section, report IAEA-TECDOC-1598. International Atomic Energy Agency, Vienna

Sungpyo K, Aga DS (2007) Potential ecological and human health impacts of antibiotics and antibiotic-resistant bacteria from wastewater treatment plants. J Toxicol Environ Health Part B 10(8):559–573

Takács E, Wojnárovits L, Pálfi TS, Emmi S (2008) Irradiation treatment of textile dye containing wastewater. In: Radiation treatment of polluted water and wastewater. Industrial applications in chemistry, report IAEA-TECDOC-1598. International Atomic Energy Agency, Vienna

Thill PG, Ager DK, Vojnovic B, Tesh SJ, Scott TB, Thomson IP (2016) Hybrid biological, electron beam and zerovalent nano iron treatment of recalcitrant metalworking fluids. Water Res 93:214–231

Trojanowicz M, Drzewicz P, Bojanowska-Czajka A, Nałęcz-Jawecki G, Gryz M, Sawicki J, Kulisa K, Wołkowicz S, Nichipor G, Zimek Z (2008) Application of ionizing radiation for removal of pesticides from groundwaters and wastes. In: Radiation treatment of polluted water and wastewater. Industrial applications in chemistry, report IAEA-TECDOC-1598. International Atomic Energy Agency, Vienna

Urase T, Kikuta T (2005) Separate estimation of adsorption and degradation of pharmaceutical substances and estrogens in the environment in the activated sludge process. Water Res 39:1289–1300

Vieno NM, Tuhkanen T, Kronberg L (2006) Removal of pharmaceuticals in drinking water treatment: effect of chemical coagulation. Environ Technol 27:183–192

Wang C, Shi H, Adams CD, Gamagedara S, Stayton I, Timmon T, Ma Y (2011) Investigation of pharmaceuticals in Missouri natural and drinking water using high performance liquid chromatography-tandem mass spectrometry. Water Res 45:1818–1828

Wang L, Batchelor B, Pillai SD, Botlaguduru VSV (2016) Electron beam treatment for potable water reuse: removal of bromate and perfluorooctanoic acid. Chem Eng J 302:58–68

Westerhoff P, Yoon Y, Snyder S, Wert E (2005) Fate of endocrine-disrupter, pharmaceuticals and personal care product chemicals during simulated drinking water treatment process. Environ Sci Technol 39:6649–6663

Wu Q, Shi H, Adams CD, Timmons T, Ma Y (2012) Oxidative removal of selected endocrine-disruptors and pharmaceuticals in drinking water treatment systems, and identification of degradation products of triclosan. Sci Total Environ 439:18–25

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Capodaglio, A.G. High-energy oxidation process: an efficient alternative for wastewater organic contaminants removal. Clean Techn Environ Policy 19, 1995–2006 (2017). https://doi.org/10.1007/s10098-017-1410-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10098-017-1410-5