Abstract

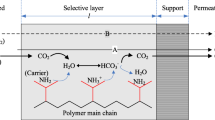

Many investigations have conducted life cycle assessments (LCA) of the most commonly discussed routes of carbon capture and storage (CCS): post-combustion with amine wash separation; oxyfuel using cryogenic air separation and pre-combustion by integrated gasification combined cycle (IGCC) using physical separation. A research alliance developed corresponding separation systems using different types of membranes to allow a more energy efficient separation process: polyactive polymeric membranes for post-combustion, ceramic membranes for oxyfuel and metallic membranes for IGCC separation. By conducting an LCA, the study examines the actual greenhouse gas emissions and other environmental impacts of the new membrane separation technologies, together with concepts implementing the more common technologies. The reference systems represent today’s state-of-the-art supercritical coal fired power plant in Germany, together with a more advanced ultra-supercritical plant operating at 700 °C without CO2 capture. The results demonstrate that among the three reference power plants the IGCC is the superior concept due to the highest efficiency. Regarding climate change, the IGCC power plants with CO2 capture are still the best concepts. When other environmental impacts are considered, the capture technologies are inferior. The membrane concepts show the overall better results in comparison to the conventional capture technologies. The environmental impacts for membrane applications add a new range of findings to the field of CCS LCAs. Now the results for several different approaches can be compared directly for the first time.

Similar content being viewed by others

References

Anheden M, Burchhardt U, Ecke H, Faber R, Jidinger O, Giering R et al (2011) Overview of operational experience and results from test activities in Vattenfall’s 30 MWth oxyfuel pilot plant in Schwarze Pumpe. In: Energy Procedia, pp 941–950. doi:10.1016/j.egypro.2011.01.140

Baumann S, Serra JM, Lobera MP, Escolástico S, Schulze-Küppers F, Meulenberg WA (2011) Ultrahigh oxygen permeation flux through supported Ba0.5Sr0.5Co0.8Fe0.2O3−δ membranes. J Membr Sci 377:198–205. doi:10.1016/j.memsci.2011.04.050

Berrill P, Arvesen A, Scholz Y, Gils HC, Hertwich EG (2016) Environmental impacts of high penetration renewable energy scenarios for Europe. Environ Res Lett 11:014012

Brinkmann T, Pohlmann J, Bram M, Zhao L, Tota A, Escalona NJ et al (2015) Investigating the influence of the pressure distribution in a membrane module on the cascaded membrane system for post-combustion capture. Int J Greenh Gas Control 39:194–204

Brunetti A, Drioli E, Lee YM, Barbieri G (2014) Engineering evaluation of CO2 separation by membrane gas separation systems. J Membr Sci 454:305–315. doi:10.1016/j.memsci.2013.12.037

Carbo MC, Jansen D, Haije WG, Verkooijen AHM (2006) Advanced membrane reactors for fuel decarbonisation in IGCC: H2 or CO2 separation? In: 5th Annual conference on carbon capture and sequestration, Alexandria, VA, p 9

Cassano A, Basile A (2013) Integrating different membrane operations and combining membranes with conventional separation techniques in industrial processes. Handb Membr React 2:296–343. doi:10.1533/9780857097347.1.296

Castillo R (2011a) Thermodynamic analysis of a hard coal oxyfuel power plant with high temperature three-end membrane for air separation. Appl Energy 88(5):1480–1493. doi:10.1016/j.apenergy.2010.10.044

Castillo R (2011b) Thermodynamic evaluation of membrane based oxyfuel power plants with 700 °C technology. Energy Procedia 4:1026–1034

Chiesa P, Lozza GG, Kreutz TG (2007) CO2 sequestration from IGCC power plants by means of metallic membranes. J Eng Gas Turbines Power 129:123–134

Chiesa P, Manzolini G, Romano MC (2015) The use of membranes in oxygen and hydrogen separation in integrated gasification combined cycle (IGCC) power plants. Membr React Energy Appl Basic Chem Prod. doi:10.1016/B978-1-78242-223-5.00013-3

Corsten M, Ramírez A, Shen L, Koornneef J, Faaij A (2013) Environmental impact assessment of CCS chains: lessons learned and limitations from LCA literature. Int J Greenh Gas Control 13:59–71. doi:10.1016/j.ijggc.2012.12.003

Cuéllar-Franca RM, Azapagic A (2015) Carbon capture, storage and utilisation technologies: a critical analysis and comparison of their life cycle environmental impacts. J CO2 Util 9:82–102. doi:10.1016/j.jcou.2014.12.001

Czyperek M, Zapp P, Bouwmeester HJM, Modigell M, Ebert K, Voigt I et al (2010) Gas separation membranes for zero-emission fossil power plants: MEM-BRAIN. J Membr Sci 359:149–159. doi:10.1016/j.memsci.2010.04.012

Dillon DJ, Panesar RS, Wall RA, Allam RJ, White V, Gibbins J et al (2005) Oxy-combustion processes for CO2 capture from advanced supercritical PF and NGCC power plant. In: 7th International conference on greenhouse gas control technologies, London, Elsevier, pp 211–220

Doka G (2007) Critical review of diploma-Thesis No. 2077M505 “Life Cycle Assessment of Selected Technologies for CO2 Transport and Sequestration” (C. Wildbolz). www.doka.ch ecoinvent2 www.ecoinvent.org

Eiberger J, Wilkner K, Reetz C, Sebold D, Jordan N, de Graaff M et al (2015) Influence of coal power plant exhaust gas on the structure and performance of ceramic nanostructured gas separation membranes. Int J Greenh Gas Control 43:46–56. doi:10.1016/j.ijggc.2015.10.005

Engels S, Beggel F, Modigell M, Stadler H (2010) Simulation of a membrane unit for oxyfuel power plants under consideration of realistic BSCF membrane properties. J Membr Sci 359:93–101

Franz J, Maas P, Scherer V (2014) Economic evaluation of pre-combustion CO2-capture in IGCC power plants by porous ceramic membranes. Appl Energy 130:532–542

Goldbach A, Bao F, Qi C, Bao C, Zhao L, Hao C et al (2015) Evaluation of Pd composite membrane for pre-combustion CO2 capture. Int J Greenh Gas Control 33:69–76. doi:10.1016/j.ijggc.2014.12.003

GaBi6.0 GaBi 6.0 (Ganzheitliche Bilanzierung) Software. www.thinkstep.com/software/gabi-lca

IEA (2010) Energy technology perspectives: scenarios and strategies to 2050. OECD/IEA, Paris

IPCC (2014) Climate change 2014: synthesis report. In: Contribution of working groups I, II and III to the 5th assessment report of the intergovernmental panel on climate change. Geneva, Switzerland

ISO 14040/14044 (2006) Environmental management: life cycle assessment—principles and framework (14040)/requirements and guidelines (14044) vol 14040/14044. International Organization for Standardization, Genf (Schweiz)

Jansen D, Gazzani M, Manzolini G, Ev D, Carbo M (2015) Pre-combustion CO2 capture. Int J Greenh Gas Control 40:167–187. doi:10.1016/j.ijggc.2015.05.028

Khalilpour R, Mumford K, Zhai H, Abbas A, Stevens G, Rubin ES (2015) Membrane-based carbon capture from flue gas: a review. J Clean Prod 103:286–300. doi:10.1016/j.jclepro.2014.10.050

Koutsonikolas DE, Kaldis SP, Pantoleontos GT, Zaspalis VT, Sakellaropoulos GP (2013) Techno-economic assessment of polymeric, ceramic and metallic membranes integration in an advanced IGCC process for H2 production and CO2 capture vol 35. doi:10.3303/CET1335119

Markewitz P, Kuckshinrichs W, Leitner W, Linssen J, Zapp P, Bongartz R et al (2012) Worldwide innovations in the development of carbon capture technologies and the utilization of CO2. Energy Environ Sci 5:7281–7305. doi:10.1039/C2EE03403D

Mass P, Nauels N, Zhao L, Markewitz P, Scherer V, Modigell M et al (2016) Energetic and economic evaluation of membrane based carbon capture routes for power plant processes. Int J Greenh Gas Control 44:124–139

Moser P, Schmidt S, Sieder G, Garcia H, Stoffregen T (2011) Performance of MEA in a long-term test at the post-combustion capture pilot plant in Niederaussem. Int J Greenh Gas Control 5:620–627. doi:10.1016/j.ijggc.2011.05.011

Nauels N, Beggel F, Engels S, Modigell M (2010) MIEC membranes in an oxyfuel power plant process. In: 20th Annual meeting of the North American membrane society and 11th international conference on inorganic membranes 2010, NAMS/ICIM 2010, pp 586–588

Park HJ, Kim PJ, Son HS (2009) Oxygen permeation and stability of Ba0.5Sr0.5Co0.8Fe0.2O3−δ membrane according to trace elements and oxygen partial pressure in synthetic air. Energy Procedia 1:369–374. doi:10.1016/j.egypro.2009.01.050

Rubin ES, Davison JE, Herzog HJ (2015) The cost of CO2 capture and storage. Int J Greenh Gas Control 40:378–400. doi:10.1016/j.ijggc.2015.05.018

Schiebahn S (2014) Optimized CO2 capture in IGCC power plants by water gas shift membrane reactors. (in German) Schriften des Forschungszentrums Jülich. Energy Environ 213:203

Schiebahn S, Zhao I, Grünewald M (2011) Physical absorption materials for CO2 capture. In: Stolten D, Scherer V (eds) Process engineering for CCS power plants: efficient carbon capture for coal power plants. Wiley, New York, pp 175–240

Schreiber A, Zapp P, Marx J (2012) Meta-analysis of life cycle assessment studies on electricity generation with carbon capture and storage. J Ind Ecol 16:S155–S168. doi:10.1111/j.1530-9290.2011.00435.x

Schreiber A, Marx J, Zapp P (2013) Environmental assessment of a membrane-based air separation for a coal-fired oxyfuel power plant. J Membr Sci 440:122–133. doi:10.1016/j.memsci.2013.03.026

Schulze-Küppers F, Baumann S, Meulenberg WA, Stöver D, Buchkremer HP (2013) Manufacturing and performance of advanced supported Ba0.5Sr0.5Co0.8Fe0.2O3-δ (BSCF) oxygen transport membranes. J Membr Sci 433:121–125. doi:10.1016/j.memsci.2013.01.028

Singh B, Strømman AH, Hertwich EG (2011) Comparative life cycle environmental assessment of CCS technologies. Int J Greenh Gas Control 5:911–921. doi:10.1016/j.ijggc.2011.03.012

Stadler H, Beggel F, Habermehl M, Persigehl B, Kneer R, Modigell M et al (2011) Oxyfuel coal combustion by efficient integration of oxygen transport membranes. Int J Greenh Gas Control 5:7–15. doi:10.1016/j.ijggc.2010.03.004

Troy S (2012) CO2 free coal enegy by using carbon capture and storage andbiomass co-incineration (in German). Doctor Thesis, Ruhr-University Bochum

Vente JF, Haije WG, Ijpelaan R, Rusting FT (2006) On the full-scale module design of an air separation unit using mixed ionic electronic conducting membranes. J Membr Sci 278:66–71. doi:10.1016/j.memsci.2005.10.044

VGB PowerTech e.V (2004) Concept study reference power plant North Rhine-Westphalia (RKW NRW) (in German). VGB PowerTech Service GmbH, Essen

VGB PowerTech e.V (2010) Pre-engineering study NRW power plant 700 °C’ NRWPP700. VGB PowerTech e.V, Essen

Viebahn P, Nitsch J, Fischedick M, Esken A, Schüwer D, Supersberger N et al (2007) Comparison of carbon capture and storage with renewable energy technologies regarding structural, economic, and ecological aspects in Germany. Int J Greenh Gas Control 1:121–133. doi:10.1016/S1750-5836(07)00024-2

Viebahn P, Daniel V, Samuel H (2012) Integrated assessment of carbon capture and storage (CCS) in the German power sector and comparison with the deployment of renewable energies. Appl Energy 97:238–248. doi:10.1016/j.apenergy.2011.12.053

Volkart K, Bauer C, Boulet C (2013) Life cycle assessment of carbon capture and storage in power generation and industry in Europe. Int J Greenh Gas Control 16:91–106. doi:10.1016/j.ijggc.2013.03.003

Wildbolz C (2007) Life cycle assessment of selected technologies for CO2 transport and sequestration. Diploma-Thesis No. 2077M505, Swiss Federal Institute of Technology Zürich, Institute of Environmental Engineering (IfU), ETH Zürich

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Troy, S., Schreiber, A. & Zapp, P. Life cycle assessment of membrane-based carbon capture and storage. Clean Techn Environ Policy 18, 1641–1654 (2016). https://doi.org/10.1007/s10098-016-1208-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10098-016-1208-x