Abstract

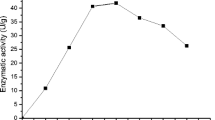

This work was aimed at producing inulinase by solid-state fermentation of sugarcane bagasse, using factorial design to identify the effect of corn steep liquor (CSL) and soybean bran concentration, particle size of bagasse and size of inoculum. Maximum inulinase activity achieved was 250 U per g of dry substrate (gds) at 20% (w/w) of CSL, 5% (w/w) of soybean bran, 1 × 1010 cells mL−1 and particle size of bagasse in the range 9/32 mesh. The use of soybean bran decreased the time to reach maximum activity from 96 to 24 h and the maximum productivity achieved was 8.87 U gds−1 h−1. The maximum activity was obtained at pH 5.0 and 55.0°C. Within the investigated range, the enzyme extract was more thermostable at 50.0°C, showing a D-value of 123.1 h and deactivation energy of 343.9 kJ gmol−1. The extract showed highest stability from pH 4.5 to 4.8. Apparent K m and V max are 7.1 mM and 17.79 M min−1, respectively.

Similar content being viewed by others

References

Nigam P, Singh D (1994) Solid state (substrate) fermentation systems and their application in biotechnology. J Basic Microbiol 34:404–423

Pandey A, Soccol CR, Mitchell DA (2000) New development in solid state fermentation: I—bioprocesses and bioproducts. Process Biochem 35:1153–1169

Pandey A, Soccol CR, Nigam P, Soccol VT (2000) Biotechnological potential of agro-industrial residues: I sugarcane bagasse. Bioresour Technol 74:81–87

Pandey A (1992) Recent developments in solid state fermentation. Process Biochem 27:109–117

Robinson T, Nigam P (2003) Bioreactor design for protein enrichment of agricultural residues by solid state fermentation. Biochem Eng J 13:197–203

Pandey A (2003) Solid state fermentation. Biochem Eng J 13:81–84

Barrios-González J, González H, Mejía A (1993) Effect of size particle, packing density and agitation on penicillin production in solid state fermentation. Biotechnol Adv 11:539–547

Dyaz-Godynez G, Soriano-Santos J, Augur C, Viniegra-Gonzalez G (2001) Exopectinases produced by Aspergillus niger in solid state and submerged fermentation: a comparative study. J Ind Microbiol Biotechnol 26:271–275

Selvakumar P, Pandey A (1999) Solid state fermentation for the synthesis of inulinase from Staphylococcus sp. and Kluyveromyces marxianus. Process Biochem 34:851–858

Zhang L, Zhao C, Zhu D, Ohta Y, Wanga Y (2004) Purification and characterization of inulinase from Aspergillus niger AF10 expressed in Pichia pastoris. Protein Expr Purif 35:272–275

Otha K, Suetsugu N, Nakamura T (2002) Purification and properties of an extracellular inulinase from Rhizopus sp. strain TN-96. J Biosci Bioeng 94:78–80

Vandamme EJ, Derycke DG (1983) Microbial inulinases: fermentation process, properties and application. Adv Appl Microbiol 29:139–176

Fachin D, Loey AMV, Nguyen BL, Verlent I, Indrawati I, Hedricks ME (2002) Comparative study of the inactivation kinetics of pectinmethylesterase in tomato juice and purified form. Biotechnol Prog 18:739–744

Rodrigues MI, Iemma AF (2005) Planejamento de Experimentos e Otimização de Processos: Uma estratégia seqüencial de planejamentos. Casa do Pão, Campinas, Brazil

Miller GL (1959) Use of dinitrosalisylic acid reagent for determination of reducing sugar. Anal Chem 31:426–428

Santisteban-Silva BOY, Maugeri F (2005) Agitation, aeration and shear stress as key factors in inulinase production by Kluyveromyces marxianus. Enzyme Microb Tech 36:717–724

Mazutti M, Bender JP, Treichel H, Di Luccio M (2006) Optimization on inulinase production by solid state fermentation using sugar cane as substrate. Enzyme Microb Technol 39:56–59

Ikasari L, Mitchell DA (1994) Protease production by Rhizopus oligosporus in solid-state fermentation. World J Microbiol Biotechnol 10:320–324

Saxena S, Saxena RK (2004) Statistical optimization of tannase production from Penicillium variable using fruits (chebulic myrobalan) of Terminalia chebula. Biotechnol Appl Biochem 39:99–106

Bender JP, Mazutti MA, Oliveira D, Treichel H, Di Luccio M (2006) Inulinase production by Kluyveromyces marxianus NRRL Y-7571 using solid state fermentation. Appl Biochem Biotech 32:951–958

Brand D, Pandey A, Rodriguez-Leon JA, Roussos S, Brand I, Soccol CR (2001) Packed bed column fermenter and kinetic modelling for upgrading the nutritional quality of coffee husk in solid state fermentation. Biotechnol Prog 17:1065–1070

Pessoa A, Vitolo M (1999) Inulinase from Kluyveromyces marxianus: culture medium composition and enzyme extraction. Braz J Chem Eng 16:237–245

Cazetta ML, Martins PMM, Monti R, Contiero J (2005) Yacon (Polymnia sanchifolia) extract as a substrate to produce inulinase by Kluyveromyces marxianus var. bulgaricus. J Food Eng 66:301–305

Cruz-Guerrero A, Garcia-Peña I, Barzana E, Racia-Garibay M, Gómez-Ruiz L (1995) Kluyveromyces marxianus CDBB-L-278: a wild inulinase hyperproducing strain. J Ferment Bioeng 80:159–163

Catana R, Ferreira BS, Cabral JM S, Fernandes P (2005) Immobilization of inulinase for sucrose hydrolysis. Food Chem 91:517–520

Gill PK, Manhas RK, Singh P (2006) Comparative analysis of thermostability of extracellular inulinase activity from Aspergillus fumigatus with commercially available (Novozyme) inulinase. Bioresour Technol 97:355–358

Fullbrook PD (1996) Practical applied kinetics. In: Godfrey T, West S (eds) Industrial enzymology, 2nd edn. Stockholm Press, New York, pp 483–540

Acknowledgments

The authors thank FAPERGS for the financial support for this work and scholarships and Laboratório de Engenharia de Bioprocessos (FEA/UNICAMP) for providing the strain used in this work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mazutti, M., Ceni, G., Luccio, M.D. et al. Production of inulinase by solid-state fermentation: effect of process parameters on production and preliminary characterization of enzyme preparations. Bioprocess Biosyst Eng 30, 297–304 (2007). https://doi.org/10.1007/s00449-006-0096-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00449-006-0096-6