Abstract

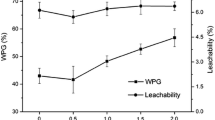

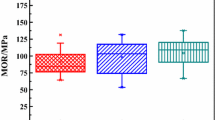

Wood furfurylation is a very promising modification process, which can greatly improve several important properties of wood simultaneously. The polymerization degree of furfuryl alcohol (FA) in wood significantly influences the performances of modified wood. However, it is normally time-consuming and expensive to determine the curing parameters of a new FA solution formula for a target wood species, as the process requires lots of lab-scale experiments. To address this challenge, nanoindentation was used to determine the hardness and elastic modulus of FA resin which are cured with different catalyst content, curing time and curing temperature, assuming that these mechanical properties should closely relate to the polymerization degree of cured FA (resin). Single-factor experiments were designed to obtain preliminary curing parameters. Three key curing parameters were selected, namely the catalyst content of maleic anhydride (1.5, 3, 5 %), curing time (2, 3, 4, 5, 6 h) and curing temperature (95, 105, 115, 125 °C). The proposed set of curing parameters based on the nanoindentation results are 3 % maleic anhydride, 3 h curing time and 105 °C curing temperature. This set of parameters was slightly modified and then used as the starting process parameters for Masson pine modification, which resulted in greatly improved wood properties. Therefore, the method proposed in this study offers an effective and time-saving means of developing new processes of wood furfurylation.

Similar content being viewed by others

References

Alfredsen G, Westin M (2009) Durability of modified wood-laboratory vs field performance. In: Proceeding of the 4th European conference on wood modification, Stockholm, Sweden, pp 27–29

Bobrowski A, Grabowska B (2012) The impact of temperature on furan resin and binder structure. Metall Foundry Eng 38:73–80

Epmeier H, Johansson M, Kliger R (2007) Material properties and their interrelation in chemically modified clear wood of Scots pine. Holzforschung 61(1):34–42

Esteves B, Nunes L, Pereira H (2011) Properties of furfurylated wood (Pinus pinaster). Eur J Wood Prod 69(4):521–525

GB/T1928 (2009) General requirements for physical and mechanical teats of wood. Standards press of China, Beijing

Hadi YS, Westin M, Rasyid E (2005) Resistance of furfurylated wood to termite attack. For Prod J 55(11):85–88

Herold N, Dietrich T, Grigsby WJ (2013) Effect of maleic anhydride content and ethanol dilution on the polymerization of furfuryl alcohol in wood veneer studied by differential scanning calorimetry. Bioresources 8(1):1064–1075

Jiang ZH, Yu Y, Qin DC, Wang G, Zhang B, Fu YJ (2006) Pilot investigation of the mechanical properties of wood flooring paint films by in situ imaging nanoindentation. Holzforschung 60(6):698–701

Kelley SS, Young RA, Rammon RM, Gillespie RH (1982) Bond formation by wood surface reactions part IV analysis of furfuryl alcohol, tannin and maleic acid bridging agents. J Wood Chem Technol 2(3):317–342

Lande S, Westin M, Schneider MH (2004) Properties of furfurylated wood. Scand J For Res 19(5):22–30

Lande S, Westin M, Schneider MH (2008) Development of modified wood products based on furan chemistry. Mol Cryst Liq Cryst 484(1):367–378

Li WJ, Wang HK, Ren D, Yu YS, Yu Y (2015) Wood modification with furfuryl alcohol catalysed by a new composite acidic catalyst. Wood Sci Technol 49(4):845–856

Meng Y, Wang S, Cai Z, Young TM, Du G, Li Y (2013) A novel sample preparation method to avoid influence of embedding medium during nano-indentation. Appl Phys A 110(2):361–369

Nordstierna L, Lande S, Westin M (2008) Towards novel wood-based materials: chemical bonds between lignin-like model molecules and poly (furfuryl alcohol) studied by NMR. Holzforschung 62(6):709–713

Park BD, Frihart CR, Yu Y, Singh AP (2013) Hardness evaluation of cured urea-formaldehyde resins with different formaldehyde/urea mole ratios using nanoindentation method. Eur Polymer J 49(10):3089–3094

Rayón E, López J, Arrieta MP (2013) Mechanical characterization of microlaminar structures extracted from cellulosic materials using nanoindentation technique. Cellulose Chem Technol 47(5–6):345–351

Schneider MH (1995) New call wall and cell lumen wood polymer composites. Wood Sci Technol 29(2):121–127

Wang H, Yao J (2006) Use of poly (furfuryl alcohol) in the fabrication of nanostructured carbons and nanocomposites. Ind Eng Chem Res 45(19):6393–6404

Westin M (1995) Development and evaluation of new alternative wood preservation treatments. Mid-term status report to the Swedish Council for Forestry and Agricultural Research

Wimmer R, Lucas BN, Tsui TY, Oliver WC (1997) Longitudinal hardness and Young’s modulus of spruce tracheid secondary walls using nanoindentation technique. Wood Sci Technol 31(2):131–141

Wu Y, Wang S, Rial T, Xing C, Zhang Y, Cai Z (2010) Evaluation of elastic modulus and hardness of crop stalks cell walls by nanoindentation. Bioresour Technol 101(8):2867–2871

Yu Y, Fei BH, Wang HK, Tian GL (2011) Longitudinal mechanical properties of cell wall of Masson pine (Pinus massoniana Lamb) related to different moisture contents by nanoindentation. Holzforschung 65(1):121–126

Acknowledgments

We would like to thank the Special Research Funds for Forestry Public Welfare of China (201404510) and Beijing City Board of Education Key Lab Co-built Project for financial support. We also thank Mr. Oliver Firth, International Network for Bamboo and Rattan (INBAR), for his revision to the manuscript.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, W., Zhang, X.X., Yu, Z. et al. Determining the curing parameters of furfuryl alcohol for wood modification by nanoindentation. Eur. J. Wood Prod. 75, 81–87 (2017). https://doi.org/10.1007/s00107-016-1057-7

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00107-016-1057-7