Abstract

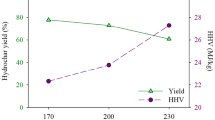

Tobacco residues produced from domestic cigarette industry are an abundant biomass resource which have the potential to be exploited and utilized as solid fuel. In the present study, a comprehensive investigation was performed on the fuel properties of hydrochars which were derived from hydrothermal carbonization (HTC) of tobacco residues in the presence of minute amount of graphene oxide (GO). The effect of HTC temperature and residence time on the chemical compositions, structure, and combustion performance of the resultant GO-assisted hydrochars was evaluated. The carbon content and energy densification increased with the hydrothermal treatment intensity accompanying with the decline in hydrogen and oxygen contents. Meanwhile, the combustion behavior of hydrochars was analyzed based on the thermogravimetric curves and isoconversional Kissinger-Akahira-Sunose method. The activation energy varied with conversion degrees for the tested samples, indicating the complexity of hydrochar combustion. Notably, the decreased activation energies for GO-assisted hydrochars may indicate the catalytic role of GO during the combustion process of components in hydrochars.

Similar content being viewed by others

References

Pradhan P, Mahajani SM, Arora A (2018) Production and utilization of fuel pellets from biomass: a review. Fuel Process Technol 181:215–232

Yang W, Wang H, Zhang M, Zhu J, Zhou J, Wu S (2016) Fuel properties and combustion kinetics of hydrochar prepared by hydrothermal carbonization of bamboo. Bioresour Technol 205:199–204

Boström D, Skoglund N, Grimm A, Boman C, Öhman M, Broström M, Backman R (2012) Ash transformation chemistry during combustion of biomass. Energy Fuel 26:85–93

Reza MT, Rottler E, Herklotz L, Wirth B (2015) Hydrothermal carbonization (HTC) of wheat straw: influence of feedwater pH prepared by acetic acid and potassium hydroxide. Bioresour Technol 182:336–344

Suwelack K, Wüst D, Zeller M, Kruse A, Krümpel J (2016) Hydrothermal carbonization of wheat straw—prediction of product mass yields and degree of carbonization by severity parameter. Biomass Conv Bioref 6:347–354

Hu B, Yu S-H, Wang K, Liu L, Xu X-W (2008) Functional carbonaceous materials from hydrothermal carbonization of biomass: an effective chemical process. Dalton Trans 5414–5423

Elaigwu SE, Greenway GM (2016) Microwave-assisted hydrothermal carbonization of rapeseed husk: a strategy for improving its solid fuel properties. Fuel Process Technol 149:305–312

Kang S, Li X, Fan J, Chang J (2012) Characterization of hydrochars produced by hydrothermal carbonization of lignin, cellulose, d-xylose, and wood meal. Ind Eng Chem Res 51:9023–9031

Kannan S, Gariepy Y, Vijaya Raghavan GS (2018) Optimization of the conventional hydrothermal carbonization to produce hydrochar from fish waste. Biomass Conv Bioref 8:563–576

Yang W, Shimanouchi T, Iwamura M, Takahashi Y, Mano R, Takashima K, Tanifuji T, Kimura Y (2015) Elevating the fuel properties of Humulus lupulus, Plumeria alba and Calophyllum inophyllum L. through wet torrefaction. Fuel 146:88–94

Cai J, Li B, Chen C, Wang J, Zhao M, Zhang K (2016) Hydrothermal carbonization of tobacco stalk for fuel application. Bioresour Technol 220:305–311

Chen X, Ma X, Peng X, Lin Y, Yao Z (2018) Conversion of sweet potato waste to solid fuel via hydrothermal carbonization. Bioresour Technol 249:900–907

Fang J, Zhan L, Ok YS, Gao B (2018) Minireview of potential applications of hydrochar derived from hydrothermal carbonization of biomass. J Ind Eng Chem 57:15–21

Wang T, Zhai Y, Zhu Y, Peng C, Xu B, Wang T, Li C, Zeng G (2017) Acetic acid and sodium hydroxide-aided hydrothermal carbonization of woody biomass for enhanced pelletization and fuel properties. Energy Fuel 31:12200–12208

Saba A, Lopez B, Lynam JG, Reza MT (2018) Hydrothermal liquefaction of loblolly pine: effects of various wastes on produced biocrude. ACS Omega 3:3051–3059

Nakason K, Panyapinyopol B, Kanokkantapong V, Viriya-empikul N, Kraithong W, Pavasant P (2018) Characteristics of hydrochar and hydrothermal liquid products from hydrothermal carbonization of corncob. Biomass Conv Bioref 8:199–210

Gao Y, Wang X, Wang J, Li X, Cheng J, Yang H, Chen H (2013) Effect of residence time on chemical and structural properties of hydrochar obtained by hydrothermal carbonization of water hyacinth. Energy 58:376–383

Saba A, Saha P, Reza MT (2017) Co-hydrothermal carbonization of coal-biomass blend: influence of temperature on solid fuel properties. Fuel Process Technol 167:711–720

Parshetti GK, Kent Hoekman S, Balasubramanian R (2013) Chemical, structural and combustion characteristics of carbonaceous products obtained by hydrothermal carbonization of palm empty fruit bunches. Bioresour Technol 135:683–689

Lynam JG, Coronella CJ, Yan W, Reza MT, Vasquez VR (2011) Acetic acid and lithium chloride effects on hydrothermal carbonization of lignocellulosic biomass. Bioresour Technol 102:6192–6199

Lynam JG, Toufiq Reza M, Vasquez VR, Coronella CJ (2012) Effect of salt addition on hydrothermal carbonization of lignocellulosic biomass. Fuel 99:271–273

Martín-Jimeno FJ, Suárez-García F, Paredes JI, Martínez-Alonso A, Tascón JMD (2015) Activated carbon xerogels with a cellular morphology derived from hydrothermally carbonized glucose-graphene oxide hybrids and their performance towards CO2 and dye adsorption. Carbon 81:137–147

Zhao X, Wang J, Chen C, Huang Y, Wang A, Zhang T (2014) Graphene oxide for cellulose hydrolysis: how it works as a highly active catalyst? Chem Commun 50:3439–3442

Krishnan D, Raidongia K, Shao J, Huang J (2014) Graphene oxide assisted hydrothermal carbonization of carbon hydrates. ACS Nano 8:449–457

Gao W, Chen K, Xiang Z, Yang F, Zeng J, Li J, Yang R, Rao G, Tao H (2013) Kinetic study on pyrolysis of tobacco residues from the cigarette industry. Ind Crop Prod 44:152–157

García R, Pizarro C, Lavín AG, Bueno JL (2013) Biomass proximate analysis using thermogravimetry. Bioresour Technol 139:1–4

Channiwala SA, Parikh PP (2002) A unified correlation for estimating HHV of solid, liquid and gaseous fuels. Fuel 81:1051–1063

He C, Giannis A, Wang J-Y (2013) Conversion of sewage sludge to clean solid fuel using hydrothermal carbonization: Hydrochar fuel characteristics and combustion behavior. Appl Energy 111:257–266

Islam MA, Kabir G, Asif M, Hameed BH (2015) Combustion kinetics of hydrochar produced from hydrothermal carbonisation of Karanj (Pongamia pinnata) fruit hulls via thermogravimetric analysis. Bioresour Technol 194:14–20

Kim D, Lee K, Park KY (2016) Upgrading the characteristics of biochar from cellulose, lignin, and xylan for solid biofuel production from biomass by hydrothermal carbonization. J Ind Eng Chem 42:95–100

Axel F, Felix Z (2010) Hydrothermal carbonization of biomass: a summary and discussion of chemical mechanisms for process engineering. Biofuels Bioprod Biorefin 4:160–177

Gu L, Li B, Wen H, Zhang X, Wang L, Ye J (2018) Co-hydrothermal treatment of fallen leaves with iron sludge to prepare magnetic iron product and solid fuel. Bioresour Technol 257:229–237

Reza MT, Yang X, Coronella CJ, Lin H, Hathwaik U, Shintani D, Neupane BP, Miller GC (2016) Hydrothermal carbonization (HTC) and pelletization of two arid land plants bagasse for energy densification. ACS Sustain Chem Eng 4:1106–1114

Wang Y, Jiang L (2017) Roles of graphene oxide in hydrothermal carbonization and microwave irradiation of distiller’s dried grains with solubles to produce supercapacitor electrodes. ACS Sustain Chem Eng 5:5588–5597

Lin Y, Ma X, Peng X, Yu Z (2016) A mechanism study on hydrothermal carbonization of waste textile. Energy Fuel 30:7746–7754

Liu Z, Quek A, Kent Hoekman S, Balasubramanian R (2013) Production of solid biochar fuel from waste biomass by hydrothermal carbonization. Fuel 103:943–949

Kambo HS, Dutta A (2015) Comparative evaluation of torrefaction and hydrothermal carbonization of lignocellulosic biomass for the production of solid biofuel. Energ Convers Manage 105:746–755

Gao P, Zhou Y, Meng F, Zhang Y, Liu Z, Zhang W, Xue G (2016) Preparation and characterization of hydrochar from waste eucalyptus bark by hydrothermal carbonization. Energy 97:238–245

Islam MA, Tan IAW, Benhouria A, Asif M, Hameed BH (2015) Mesoporous and adsorptive properties of palm date seed activated carbon prepared via sequential hydrothermal carbonization and sodium hydroxide activation. Chem Eng J 270:187–195

Sevilla M, Fuertes AB (2009) Chemical and structural properties of carbonaceous products obtained by hydrothermal carbonization of saccharides. Chem 15:4195–4203

Peng C, Zhai Y, Zhu Y, Wang T, Xu B, Wang T, Li C, Zeng G (2017) Investigation of the structure and reaction pathway of char obtained from sewage sludge with biomass wastes, using hydrothermal treatment. J Clean Prod 166:114–123

Sung YJ, Seo YB (2009) Thermogravimetric study on stem biomass of Nicotiana tabacum. Thermochim Acta 486:1–4

Liu F, Yu R, Ji X, Guo M (2018) Hydrothermal carbonization of holocellulose into hydrochar: structural, chemical characteristics, and combustion behavior. Bioresour Technol 263:508–516

Wu W, Mei Y, Zhang L, Liu R, Cai J (2015) Kinetics and reaction chemistry of pyrolysis and combustion of tobacco waste. Fuel 156:71–80

Acknowledgments

This work was supported by the CNTC’s projects (No. 110201401018), the Key Scientific Research Projects of Henan Province Universities (No. 17B550006), and the Doctoral Research Foundation (No. 2014BSJJ067) of Zhengzhou University of Light Industry.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

ESM 1

(DOCX 50 kb)

Rights and permissions

About this article

Cite this article

Liang, M., Zhang, K., Lei, P. et al. Fuel properties and combustion kinetics of hydrochar derived from co-hydrothermal carbonization of tobacco residues and graphene oxide. Biomass Conv. Bioref. 10, 189–201 (2020). https://doi.org/10.1007/s13399-019-00408-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-019-00408-2