Abstract

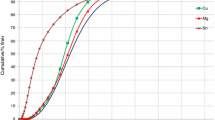

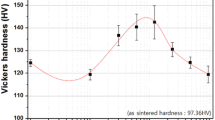

The present study investigates the effect of compaction pressure and sintering temperature on densification response and mechanical properties of the Al–3.8Cu–1Mg–0.8Si–0.3Sn (2712) alloy. The compacts were pressed at 200 and 400 MPa and sintered at temperatures ranging from 570–630°C in vacuum (10−6 Torr). The objective of the present work is to obtain an optimum sintering conditions for achieving higher sintered densities and mechanical properties. The effect of sintering temperature is evaluated by measuring the sintered density, densification parameter, microstructure, phase changes and mechanical properties. While a higher sintering temperature results in densification enhancement, it also leads to microstructural coarsening. Significant improvement in mechanical properties is obtained through age-hardening of sintered alloy under various ageing conditions (T4, T6 and T8).

Similar content being viewed by others

References

Hunt W H Jr., in Proc of First International Conference on Powder Metallurgy, Aluminum & Light Alloys for Automotive Applications, (eds) Jandeska W F Jr., and Chernenkoff R A, MPIF, Princeton (1998), p 1.

Apelian D, and Saha D, in Proc of Second International on Powder Metallurgy Aluminum & Light Alloys for Automotive Applications Conference, (eds) Jandeska W F Jr., and Chernenkoff R A, MPIF, Princeton (2000), p 1.

Savitskii A P, Liquid Phase Sintering of the Systems with Interacting Components, Russian Academy of Sciences, Moscow (1993).

Sercombe T B, Non-Conventional Sintered Aluminum Powder Alloys, Ph.D. Thesis, The University of Queensland, Australia (1998).

Schaffer G B, Hall B J, Bonner S J, Huo S H, and Sercombe T B, Acta Mater 54 (2006) 131.

Falticeanu C L, Chang I T H, Kim J S, and Cook R, Mater Sci Forum 534–536 (2007) 597.

Schaffer G B, Sercombe T B, and Lumley R N, Mater Chem Phys 67 (2001) 85.

Savitskii A P, and Martsunova L S, Porosh Metall 5 (1977) 14.

Lumley R N, and Schaffer G B, Scripta Mater 35 (1996) 589.

Martin J M, and Castro F, J Mater Process Technol 143–144 (2003) 814.

Liu Z Y, Sercombe T B, and Schaffer G B, Metall Mater Trans A 38 (2007) 1351.

Min K H, Kang S P, Lee B H, Lee J K, and Kim Y D, J Alloys Compd 419 (2006) 290.

Sundaresan R, and Ramakrishna P, Int J Powder Metall Powder Technol 14 (1978) 9.

Kehl W, and Fischmeister H F, Powder Metall 23 (1980) 113.

Lumley R N, and Schaffer G B, Scripta Mater 39 (1998) 1089.

Sercombe T B, and Schaffer G B, Acta Mater 47 (1999) 689.

Sercombe T B, and Schaffer G B, Mater Sci Eng A 268 (1999) 32.

Dudas J H, and Thompson C B, Modern. Develop. Int Powder Metall 5 (1971) 19.

Bonner S J, Sintering of an Aluminum Alloy under Pressurized Conditions, M.S. Thesis, The University of Queensland, Australia (2009).

Davies B L, and Farzin-Nia, Int J Powder Metall Powder Technol 19 (1983) 197.

Kent D, Schaffer G B, and Drennan J, Mater Sci Eng A 405 (2005) 65.

Durmus H K, and Meric C, Mater Design 28 (2007) 982.

Padmavathi C, Liquid Phase Sintering of 2712, 6711 and 7775 Aluminum Alloy and Their Properties, Ph.D Thesis, Indian Institute of Technology, India (2010).

Wagner C D, and Muilenberg G E, Handbook of X-Ray Photoelectron Spectroscopy, Perkin-Elmer Corporation, New York (1979).

MPIF Standard 41: Determination of Transverse Rupture Strength of Sintered Metal Powder Test Specimens, Standard Test Methods for Metal Powders and Powder Metallurgy Products, Metal Powder Industries Federation, Princeton (2002), p 55.

MPIF Standard 10: Tension Test Specimens for Pressed and Sintered Metal Powders, Standard Test Methods for Metal Powders and Powder Metallurgy Products, Metal Powder Industries Federation, Princeton (2002).

German R M, Powder Metallurgy Science, MPIF, Princeton (1994), p 241.

Anderson I E, and Foley J C, Surface Interface Analysis 31 (2000) 599.

German R M, Sintering Theory and Practice, Wiley, New York (1996).

German R M, Liquid Phase Sintering, Plenum Press, New York (1985).

Kauffman J G (ed), Properties of Aluminum Alloys: Tensile Creep and Fatigue Data at High and Low Temperatures, ASM International, Materials Park (1999), p 305.

Martin J M, and Castro F, Proc of Euro PM 2001 Light Alloys, EPMA, Shrewsbury (2001), p 177.

Martin J M, and Castro F, Mater Sci Forum 426–432 (2003) 107.

Schaffer G B, Yao J Y, Bonner S J, Crossin E, Pas S J, and Hill A J, Acta Mater 56 (2008) 2615.

Savitskii A P, and Romanov G N, Porosh Metall 26 (1987) 532.

Schaffer G B, and Hall B J, Metall Mater Trans A 33 (2002) 3279.

Lumley R N, Sercombe T B, and Schaffer G B, Metall Mater Trans A 30 (1999) 457.

McLeod A D, and Gabryel C M, Metall Trans A 23 (1992) 1279.

Kondoh K, Kimura A, and Watanabe R, Powder Metall 44 (2001) 161.

Gao X, Nie J F, and Muddle B C, Mater Sci Forum 217–222 (1996) 1251.

Davis J R (ed), Aluminum and Aluminum Alloys, Third ed., ASM International, Ohio (1993).

Jha A K, Sintering of 2014 Al-alloy Based Powder Metallurgical Particulate Composites, M.Tech, IIT Kanpur, India (1983).

Delarbre P, and Krehl M, Proc of Second International Conference on Powder Metallurgy Aluminum & Light Alloys for Automotive Applications, (eds) Jandeska W F Jr., and Chernenkoff R A, MPIF, Princeton (2000), p 33.

Romero A, Proc of First International Conference on Powder Metallurgy, Aluminum & Light Alloys for Automotive Applications, (eds) Jandeska W F Jr., and Chernenkoff R A, MPIF, Princeton (1998), p 51.

Dudas L, and Dean W A, Int J Powder Metall 5 (1969) 113.

ASM Metal Reference book, ASM, Metals Park, OH (1983), p 293.

Takeda Y, Kaji T, Kondoh K, and Hattori H, Proc of Powder Metallurgy Aluminum & Light Alloys for Automotive Applications Conference, (eds) Jandeska W F Jr., and Chernenkoff R A, MPIF, Princeton (1998), p 19.

Acknowledgments

The authors would like to thank Mr. Jessu Joys of AMPAL Inc., Palmerton, USA for providing the 2712 aluminum alloy powders for the present study.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Padmavathi, C., Upadhyaya, A. Sintering Behaviour and Mechanical Properties of Al–Cu–Mg–Si–Sn Aluminum Alloy. Trans Indian Inst Met 64, 345–357 (2011). https://doi.org/10.1007/s12666-011-0089-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-011-0089-2