Abstract

This study investigated the feasibility of utilizing paper sludge (PS) as feedstock in the production of composite boards that are lightweight, durable and environmentally friendly. PS samples were collected from recycled newsprint (RN), corrugated recycled (CR) and virgin pulp (VP) pulping mills in South Africa. The PS was dried and mixed with magnesium phosphate cement to produce boards in a central composite design. Three different fillers including fly ash, calcium carbonate and silica fume were also added to the mix as binder replacement. The PS was characterized before use, and the produced composite board was evaluated for mechanical and physical properties. The boards produced had medium to high density (0.52—1.12 g/cm3) that could be used for non-structural interior applications. The results showed that boards containing RN had the highest mean value for modulus of elasticity (MOE) of 769 MPa. The mean MOE for boards containing CR- and VP-PS was 357 and 411 MPa, respectively. Calcium carbonate had the best effect on the board properties. Techno-economic analysis was simulated for four different types of feedstock scenarios at different locations including a combined scenario. Sensitivity analysis revealed that decreased feedstock cost resulted in decreased minimum required selling price. The analysis also revealed that the combined scenario proved to be the most cost-effective and profitable option for the future.

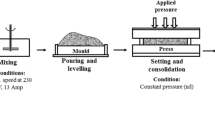

Graphic Abstract

Similar content being viewed by others

Availability of data and material

The data used and/or analyzed during the study are available from the corresponding author on request.

References

PAMSA.: Annual summary 2019 Statistics (2019).

Boshoff, S.: Characterization and fermentation of waste paper sludge for bioethanol production. Stellenbosch University, Stellenbosch (2015)

Lekha, P., Andrew, J., Gibril, M., Sithole, B.: Pulp and paper mill sludge: A potential resource for producing high-value products. TAPPSA J. 1, 16–18 (2017)

Monte, M.C., Fuente, E., Blanco, A., Negro, C.: Waste management from pulp and paper production in the European Union. Waste Manag. 293–308 (2009)

Arancon, R., Lin, C., Chan, K., Kwan, T., Luque, R.: Advances on waste valorization: new horizons for a more sustainable society. Energy Sci Eng. 1, 53–71 (2013)

Gibril, M.E., Lekha, P., Andrew, J., Sithole, B., Tesfaye, T., Ramjugernath, D.: Beneficiation of pulp and paper mill sludge: production and characterisation of functionalised crystalline nanocellulose. Clean. Technol. Environ. Policy 20, 1835–1845 (2018)

Geng, X., Zhang, S.Y., Deng, J.: Characteristics of paper mill sludge and its utilization for the manufacture of medium density fiberboard. Wood Fiber Sci. 39, 345–351 (2007)

Donahue, P.K., Aro, M.D.: Durable phosphate-bonded natural fiber composite products. Constr. Build Mater. 24, 215–219 (2010)

Migneault, S., Koubaa, A., Riedl, B., Nadji, H., Deng, J., Zhang, S.Y.: Binderless fiberboard made from primary and secondary pulp and paper sludge. Wood Fiber. Sci. 43, 180–193 (2011)

Amiandamhen, S.O., Meincken, M., Tyhoda, L.: Phosphate bonded natural fibre composites: a state of the art assessment. SN Appl. Sci. 1, 910 (2019)

Amiandamhen, S.O., Meincken, M., Tyhoda, L.: Magnesium based phosphate cement binder for composite panels: a response surface methodology for optimisation of processing variables in boards produced from agricultural and wood processing industrial residues. Ind. Crops Prod. 94, 746–754 (2016)

Amiandamhen, S.O.: Phosphate Bonded Wood and Fibre Composites. Stellenbosch University, Stellenbosch (2017)

Wagh, A.S.: Recent progress in chemically bonded phosphate ceramics. ISRN Ceram. 2013, 1–20 (2013)

Chau, C.K., Qiao, F., Li, Z.: Microstructure of magnesium potassium phosphate cement. Constr. Build. Mater. 25, 2911–2917 (2011)

Hou, D., Yan, H., Zhang, J., Wang, P., Li, Z.: Experimental and computational investigation of magnesium phosphate cement mortar. Constr. Build. Mater. 112, 331–342 (2016)

TAPPI.: Preparation of wood for chemical analysis. 2007. Report No.: T 264 cm-07.

TAPPI.: Fiber length of pulp by projection. 2013. Report No.: T 232 cm-01.

TAPPI.: Ash in wood, pulp, paper and paperboard: combustion at 525 °C. 2002. Report No.: T 211 om-02.

Sluiter, A., Ruiz, R., Scarlata, C., Sluiter, J., Templeton, D.: Determination of Extractives in Biomass: Laboratory Analytical Procedure (LAP). Tech Rep NREL/TP-510–42619. 2008;1–9.

Sluiter, A., Hames, B., Ruiz, R., Scarlata, C., Sluiter, J., Templeton, D., et al.: Determination of structural carbohydrates and lignin in biomass. Lab Anal Proced. 1617, 1–17 (2012)

Amiandamhen, S.O., Montecuccoli, Z., Meincken, M., Barbu, M.C., Tyhoda, L.: Phosphate bonded wood composite products from invasive Acacia trees occurring on the Cape Coastal plains of South Africa. Eur. J. Wood Wood Prod. 76, 437–444 (2018)

Amiandamhen, S.O., Meincken, M., Tyhoda, L.: Calcium phosphate bonded wood and fiber composite panels: production and optimization of panel properties. Holzforschung 71, 725–732 (2017)

Montgomery, D.: Design and Analysis of Experiments. Wiley, New York (2005)

ASTM.: Standard Test Methods for Evaluating Properties of Wood-Base Fiber and Particle Panel Materials. Annu. B. ASTM Stand. ASTM D1037-12. 2012.

Diaz, C.A., Afrifah, K.A., Jin, S., Matuana, L.M.: Estimation of modulus of elasticity of plastics and wood plastic composites using a Taber stiffness tester. Compos. Sci. Technol. 71, 67–70 (2011)

BS EN 634-2.: Cement-Bonded Particleboards—Specifications—Part 2: Requirements for OPC Bonded Particleboards for Use in dry, Humid and External Conditions. Br. Stand. 2007.

Irle, M., Barbu, M.C.: Wood-based panel technology. In: Thoemen, H., Irle, M., Sernek, M. (eds.) Wood-Based Panels An Introd Spec, p. 283. Brunel Unviersity, London (2010)

Sinnott, R.K.: Chemical Engineering Design, vol. 6. Butterworth-Heinemann, Oxford (2005)

Williams, A.: The production of Bioethaol and Biogas from Paper Sludge. Stellenbosch University, Stellenbosch (2017)

Turton, R., Bailie, R.C., Whiting, W.B., Shaewitz, J.A., Bhattacharya, D.: Analysis Synthesis and Design of Chemical Processes. Prentice-Hall, Upper Saddle River (2012)

Stark NM, Cai Z, Carll C. Wood-Based Composite Materials Panel Products, Glued-Laminated Timber, Structural Materials. Wood Handb - Wood as an Eng Mater. 2010;1–28.

Robus, C.L.L., van Rensburg, E., Gottumukkala, L.D., Gorgens, J.F.: Feasible process development and techno-economic evaluation of paper sludge to bioethanol conversion: South African paper mills scenario. Renew. Energy. 92, 333–345 (2016)

Farzad, S., Mandegari, M.A., Görgens, J.F.: Integrated techno-economic and environmental analysis of butadiene production from biomass. Bioresour Technol. Elsevier Ltd 239, 37–48 (2017)

The Development Studies Associate: Project profile on the establishment of particleboard producing plant. The Development Studies Associate, Addis Ababa (2008)

Ochoa de Alda JAG: Feasibility of recycling pulp and paper mill sludge in the paper and board industries. Resour. Conserv. Recycl. 52, 965–972 (2008)

Horn, R., Setterholm, V.: Fiber Morphology and New Crops. Timber Press, New York (1990)

Migneault, S., Koubaa, A., Nadji, H., Riedl, B., Zhang, S.Y., Deng, J.: Medium-density fiberboard produced using pulp and paper sludge from different pulping processes. Wood Fiber Sci. 42, 292–303 (2010)

Williams, A.: The Production of Bioethanol and Biogas From Paper Sludge. Stellenbosch University, Stellenbosch (2016)

Migneault, S., Koubaa, A., Riedl, B., Nadji, H., Deng, J., Zhang, T.: Potential of pulp and paper sludge as a formaldehyde scavenger agent in MDF resins. Holzforschung 65, 403–409 (2011)

Bester, L.M.: Development and Optimisation of a Process for Cellulose Nanoparticle Production from Waste Paper Sludge with Enzymatic Hydrolysis as an Integral Part. Stellenbosch University, Stellenbosch (2018)

Ridout AJMJC.: Valorisation of Paper Waste Sludge Using Pyrolysis Processing. University of Stellenbosch, Stellenbosch (2016).

ANSI.: Particleboard. Gaithersburg; 2016. Report No.: A208.1-2016.

Antoni, C.L., Hardjito, D.: The impact of using fly ash, silica fume and calcium carbonate on the workability and compressive strength of mortar. Procedia Eng. 125, 773–9 (2015)

Singh, D., Wagh, A.S.: Phosphate Bonded Structural Products from High Volume Wastes. United States of America: United States Patent; 1998.

Xu, B., Ma, H., Li, Z.: Influence of magnesia-to-phosphate molar ratio on microstructures, mechanical properties and thermal conductivity of magnesium potassium phosphate cement paste with large water-to-solid ratio. Cem. Concr. Res. 68, 1–9 (2015)

Zhou, X., Tan, L., Zhang, W., Lv, C., Zheng, F., Zhang, R., et al.: Enzymatic hydrolysis lignin derived from corn stover as an intrinstic binder for bio-composites manufacture: effect of fiber moisture content and pressing temperature on boards’ properties. BioResources 6, 253–264 (2011)

Zheng, D.D., Ji, T., Wang, C.Q., Sun, C.J., Lin, X.J., Hossain, K.M.A.: Effect of the combination of fly ash and silica fume on water resistance of Magnesium-Potassium Phosphate Cement. Constr. Build. Mater. 106, 415–421 (2016)

Amiandamhen, S.O., Osadolor, S.O.: Recycled waste paper–cement composite panels reinforced with kenaf fibres: durability and mechanical properties. J Mater Cycles Waste Manag, Springer Japan (2020)

Mohammed, L., Ansari, M.N.M., Pua, G., Jawaid, M., Islam, M.S.: A Review on Natural Fiber Reinforced Polymer Composite and Its Applications. Hindawi Publishing Corporation; 2015;2015.

Vickers, P., Barnes, S., Jacques, M.: The concept of peak shape [Internet]. 2019. Available from: http://pd.chem.ucl.ac.uk/pdnn/peaks/peakcon.htm

Ding, Z., Dong, B., Xing, F., Han, N., Li, Z.: Cementing mechanism of potassium phosphate based magnesium phosphate cement. Ceram. Int. 38, 6281–6288 (2012)

Ding, Z., Li, Y., Lu, C., Liu, J.: An investigation of fiber reinforced chemically bonded phosphate ceramic composites at room temperature. Materials (Basel). 11, 1–13 (2018)

Ding, Z., Li, Z.: Effect of aggregates and water contents on the properties of magnesium phospho-silicate cement. Cem. Concr. Compos. 27, 11–18 (2005)

Le Rouzic, M., Chaussadent, T., Platret, G., Stefan, L.: Mechanisms of k-struvite formation in magnesium phosphate cements. Cem. Concr. Res. 91, 117–122 (2017)

Yue, L., Jia, S., Bing, C.: Experimental study of magnesia and M/P ratio influencing properties of magnesium phosphate cement. Constr. Build. Mater. 65, 177–183 (2014)

Mngomezulu, L.B.: Phosphate-Bonded Composite Products: The Influence of Filler Materials, Biomass Type, and Processing Method on Panel Properties. Stellenbosch University, Stellenbosch (2019)

Acknowledgements

The authors would like to thank the Paper Manufacturers Association of South Africa (PAMSA) in conjunction with Kimberly-Clark (Pty) for the scholarship received by the first author.

Funding

Funding for this study was provided by the Paper Manufacturers Association of South Africa (PAMSA) in conjunction with Kimberly-Clark (Pty).

Author information

Authors and Affiliations

Contributions

LT and JG conceived the study. All the authors designed and coordinated the experiments. AC performed the experiments and drafted the manuscript. SA, LT and JG reviewed the manuscript. SA corrected and revised the manuscript. All authors approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflicts of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Chimphango, A., Amiandamhen, S.O., Görgens, J.F. et al. Prospects for Paper Sludge in Magnesium Phosphate Cement: Composite Board Properties and Techno-Economic Analysis. Waste Biomass Valor 12, 5211–5233 (2021). https://doi.org/10.1007/s12649-021-01356-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-021-01356-7