Abstract

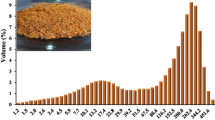

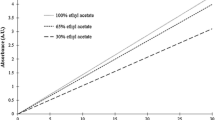

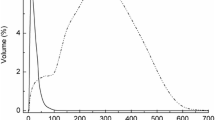

Lycopene was simultaneously extracted from tomato processing waste and size reduced into nano-ranges from 36 to 150 nm, via ultrasonic assisted nanoprecipitation technique. The effects of main processing parameters namely, organic to aqueous phase ratio, ultrasonic amplitude and time were evaluated on mean particle size, polydispersity (PDI) and lycopene content of produced nanodispersions, using response surface method based on central composite design. All studied parameters affected the selected responses significantly (p-value < 0.05). The studied characteristics’ changes were significantly (p-value < 0.05) fitted to second order polynomial regression models of studied independent parameters by quite high coefficients of determination (R2 > 0.9). The most desirable lycopene nanodispersions with mean particle size of 66.3 nm, PDI of 0.245 and lycopene content of 52 mg/g waste, were produced at organic to aqueous phase ratio of 0.5, and ultrasonication for 20 min at amplitude of 70%. The resulted insignificant differences between experimental and predicted data, certified the suitability of suggested response surface models.

Similar content being viewed by others

References

Tan, C.P., Nakajima, M.: β-Carotene nanodispersions: preparation, characterization and stability evaluation. Food Chem. 92(4), 661–671 (2005). https://doi.org/10.1016/j.foodchem.2004.08.044

Santini, A., Novellino, E.: Nutraceuticals—shedding light on the grey area between pharmaceuticals and food. Expert Rev. Clin. Pharmacol. 11(6), 545–547 (2018). https://doi.org/10.1080/17512433.2018.1464911

Santini, A., Tenore, G.C., Novellino, E.: Nutraceuticals: a paradigm of proactive medicine. Eur. J. Pharm. Sci. 96, 53–61 (2017). https://doi.org/10.1016/j.ejps.2016.09.003

Poojary, M.M., Passamonti, P.: Extraction of lycopene from tomato processing waste: kinetics and modelling. Food Chem. 173, 943–950 (2015). https://doi.org/10.1016/j.foodchem.2014.10.127

Naviglio, D., Pizzolongo, F., Ferrara, L., Aragòn, A., Santini, A.: Extraction of pure lycopene from industrial tomato by-products in water using a new high-pressure process. J. Sci. Food Agric. 88(14), 2414–2420 (2008). https://doi.org/10.1002/jsfa.3334

Gervasi, T., Pellizzeri, V., Benameur, Q., Gervasi, C., Santini, A., Cicero, N., Dugo, G.: Valorization of raw materials from agricultural industry for astaxanthin and β-carotene production by Xanthophyllomyces dendrorhous. Nat. Prod. Res. 32(13), 1554–1561 (2018). https://doi.org/10.1080/14786419.2017.1385024

Anarjan, N., Jafarizadeh-Malmiri, H., Nehdi, I.A., Sbihi, H.M., Al-Resayes, S.I., Tan, C.P.: Effects of homogenization process parameters on physicochemical properties of astaxanthin nanodispersions prepared using a solvent-diffusion technique. Int. J. Nanomed. 10, 1109–1118 (2015). https://doi.org/10.2147/IJN.S72835

Shi, J., Xue, S.J., Wang, B., Wang, W., Ye, X., Quek, S.Y.: Optimization of formulation and influence of environmental stresses on stability of lycopene-microemulsion. LWT Food Sci. Technol. 60(2), 999–1008 (2015). https://doi.org/10.1016/j.lwt.2014.10.066

Anarjan, N., Tan, C.P., Ling, T.C., Lye, K.L., Malmiri, H.J., Nehdi, I.A., Cheah, Y.K., Mirhosseini, H., Baharin, B.S.: Effect of organic-phase solvents on physicochemical properties and cellular uptake of astaxanthin nanodispersions. J. Agric. Food Chem. 59(16), 8733–8741 (2011). https://doi.org/10.1021/jf201314u

Periasamy, V.S., Athinarayanan, J., Alshatwi, A.A.: Anticancer activity of an ultrasonic nanoemulsion formulation of Nigella sativa L. essential oil on human breast cancer cells. Ultrason. Sonochem. 31, 449–455 (2016). https://doi.org/10.1016/j.ultsonch.2016.01.035

Luque de Castro, M.D., Priego-Capote, F.: Ultrasound-assisted preparation of liquid samples. Talanta 72(2), 321–334 (2007). https://doi.org/10.1016/j.talanta.2006.11.013

Kaur, K., Kumar, R., Arpita, Goel, S., Uppal, S., Bhatia, A., Mehta, S.K.: Physiochemical and cytotoxicity study of TPGS stabilized nanoemulsion designed by ultrasonication method. Ultrason. Sonochem. 34, 173–182 (2017). https://doi.org/10.1016/j.ultsonch.2016.05.037

Kaur, K., Kumar, R., Mehta, S.K.: Formulation of saponin stabilized nanoemulsion by ultrasonic method and its role to protect the degradation of quercitin from UV light. Ultrason. Sonochem. 31, 29–38 (2016). https://doi.org/10.1016/j.ultsonch.2015.11.017

Abbas, S., Bashari, M., Akhtar, W., Li, W.W., Zhang, X.: Process optimization of ultrasound-assisted curcumin nanoemulsions stabilized by OSA-modified starch. Ultrason. Sonochem. 21(4), 1265–1274 (2014). https://doi.org/10.1016/j.ultsonch.2013.12.017

Xu, Y., Pan, S.: Effects of various factors of ultrasonic treatment on the extraction yield of all-trans-lycopene from red grapefruit (Citrus paradise Macf.). Ultrason. Sonochem. 20(4), 1026–1032 (2013). https://doi.org/10.1016/j.ultsonch.2013.01.006

Naviglio, D., Caruso, T., Iannece, P., Aragòn, A., Santini, A.: Characterization of high purity lycopene from tomato wastes using a new pressurized extraction approach. J. Agric. Food Chem. 56(15), 6227–6231 (2008). https://doi.org/10.1021/jf703788c

Anarjan, N., Jouyban, A.: Preparation of lycopene nanodispersions from tomato processing waste: effects of organic phase composition. Food Bioprod. Process. 103, 104–113 (2017). https://doi.org/10.1016/j.fbp.2017.03.003

Tang, S.Y., Manickam, S., Wei, T.K., Nashiru, B.: Formulation development and optimization of a novel Cremophore EL-based nanoemulsion using ultrasound cavitation. Ultrason. Sonochem. 19(2), 330–345 (2012). https://doi.org/10.1016/j.ultsonch.2011.07.001

Eh, A.L.-S., Teoh, S.-G.: Novel modified ultrasonication technique for the extraction of lycopene from tomatoes. Ultrason. Sonochem. 19(1), 151–159 (2012). https://doi.org/10.1016/j.ultsonch.2011.05.019

Anarjan, N., Mirhosseini, H., Baharin, B.S., Tan, C.P.: Effect of processing conditions on physicochemical properties of astaxanthin nanodispersions. Food Chem. 123(2), 477–483 (2010). https://doi.org/10.1016/j.foodchem.2010.05.036

Anarjan, N., Nehdi, I.A., Tan, C.P.: Influence of astaxanthin, emulsifier and organic phase concentration on physicochemical properties of astaxanthin nanodispersions. Chem. Cent. J. 7(1) (2013). https://doi.org/10.1186/1752-153X-7-127

Anarjan, N., Mirhosseini, H., Baharin, B.S., Tan, C.P.: Effect of processing conditions on physicochemical properties of sodium caseinate-stabilized astaxanthin nanodispersions. LWT Food Sci. Technol. 44(7), 1658–1665 (2011). https://doi.org/10.1016/j.lwt.2011.01.013

Gaikwad, S.G., Pandit, A.B.: Ultrasound emulsification: effect of ultrasonic and physicochemical properties on dispersed phase volume and droplet size. Ultrason. Sonochem. 15(4), 554–563 (2008). https://doi.org/10.1016/j.ultsonch.2007.06.011

Konwarh, R., Pramanik, S., Kalita, D., Mahanta, C.L., Karak, N.: Ultrasonication—a complementary ‘green chemistry’ tool to biocatalysis: a laboratory-scale study of lycopene extraction. Ultrason. Sonochem. 19(2), 292–299 (2012). https://doi.org/10.1016/j.ultsonch.2011.07.010

Thorat, A.A., Dalvi, S.V.: Liquid antisolvent precipitation and stabilization of nanoparticles of poorly water soluble drugs in aqueous suspensions: recent developments and future perspective. Chem. Eng. J. 181–182, 1–34 (2012). https://doi.org/10.1016/j.cej.2011.12.044

Kentish, S., Wooster, T.J., Ashokkumar, M., Balachandran, S., Mawson, R., Simons, L.: The use of ultrasonics for nanoemulsion preparation. Innov. Food Sci. Emerg. Technol. 9(2), 170–175 (2008). https://doi.org/10.1016/j.ifset.2007.07.005

Jadhav, A.J., Holkar, C.R., Karekar, S.E., Pinjari, D.V., Pandit, A.B.: Ultrasound assisted manufacturing of paraffin wax nanoemulsions: process optimization. Ultrason. Sonochem. 23(0), 201–207 (2015). https://doi.org/10.1016/j.ultsonch.2014.10.024

Leong, T.S.H., Wooster, T.J., Kentish, S.E., Ashokkumar, M.: Minimising oil droplet size using ultrasonic emulsification. Ultrason. Sonochem. 16(6), 721–727 (2009). https://doi.org/10.1016/j.ultsonch.2009.02.008

Horn, D., Rieger, J.: Organic nanoparticles in the aqueous phase—theory, experiment, and use. Angew. Chem. Int. Ed. 40(23), 4330–4361 (2001). https://doi.org/10.1002/1521-3773(20011203)40:23%3C4330::AID-ANIE4330%3E3.0.CO;2-W

McClements, D.J.: Nanoparticle- and Microparticle-Based Delivery Systems: Encapsulation, Protection and Release of Active Compounds. Taylor and Francis, Boca Raton (2014)

Jafari, S.M., Assadpoor, E., He, Y., Bhandari, B.: Re-coalescence of emulsion droplets during high-energy emulsification. Food Hydrocolloids 22(7), 1191–1202 (2008). https://doi.org/10.1016/j.foodhyd.2007.09.006

Verma, S., Burgess, D.: Solid nanosuspensions: the emerging technology and pharmaceutical applications as nanomedicine. In: Kulshreshtha, A.K., Singh, O.N., Wall, G.M. (eds.) Pharmaceutical Suspensions: From Formulation Development to Manufacturing, pp. 285–318. Springer, New York (2010)

Luengo, E., Condón-Abanto, S., Condón, S., Álvarez, I., Raso, J.: Improving the extraction of carotenoids from tomato waste by application of ultrasound under pressure. Sep. Purif. Technol. 136, 130–136 (2014). https://doi.org/10.1016/j.seppur.2014.09.008

Periago, M.J., Rincón, F., Agüera, M.D., Ros, G.: Mixture approach for optimizing lycopene extraction from tomato and tomato products. J. Agric. Food Chem. 52(19), 5796–5802 (2004). https://doi.org/10.1021/jf049345h

Vilkhu, K., Mawson, R., Simons, L., Bates, D.: Applications and opportunities for ultrasound assisted extraction in the food industry—a review. Innov. Food Sci. Emerg. Technol. 9(2), 161–169 (2008). https://doi.org/10.1016/j.ifset.2007.04.014

Anarjan, N., Tan, C.P.: Chemical stability of astaxanthin nanodispersions in orange juice and skimmed milk as model food systems. Food Chem. 139(1–4), 527–531 (2013). https://doi.org/10.1016/j.foodchem.2013.01.012

Anarjan, N., Tan, C.P.: Effects of storage temperature, atmosphere and light on chemical stability of astaxanthin nanodispersions. J. Am. Oil Chem. Soc. 90(8), 1223–1227 (2013). https://doi.org/10.1007/s11746-013-2270-8

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Anarjan, N. Evaluation the Effects of Ultrasonic Parameters on Simultaneously Extraction and Size Reduction of Lycopene from Tomato Processing Waste. Waste Biomass Valor 11, 1929–1940 (2020). https://doi.org/10.1007/s12649-018-0528-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-018-0528-y