Abstract

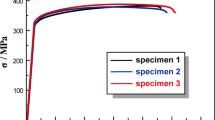

Low-cycle fatigue tests under both mechanical cyclic and thermal cyclic loadings were conducted to study the behavior of fatigue crack initiation and early propagation by means of metallographic and scanning electron microscopy (SEM). The damage mode of silicon particles has significant influence on crack behavior. Cracks are induced from fractured particles in mechanical fatigue or from debonded particles in thermal fatigue. Initiation of cracks by breaking through particles happens in particles with non-equiaxial particles, while initiation of cracks from debonded interfaces happens widely in clustered particles. For cracks induced by fracture particles, the subsequent coalescence of microcracks proceeds through the alternation of brittle fracture of particles. The sequent broken of particles takes the important part in the early propagation stage of fatigue crack.

Similar content being viewed by others

References

Samuel AM, Doty HW, Valtierra S, Samuel FH. Effect of grain refining and Sr-modification interactions on the impact toughness of Al–Si–Mg cast alloys. Mater Des. 2014;56(56):264.

Mohamed AMA, Samuel FH, Samuel AM, Doty HW, Valtierra S. Influence of tin addition on the microstructure and mechanical properties of Al–Si–Cu–Mg and Al–Si–Mg casting alloys. Metall Mater Trans A. 2008;39(3):490.

Wang QG, Davidson CJ. Solidification and precipitation behaviour of Al–Si–Mg casting alloys. J Mater Sci. 2001;36(3):739.

Caceres CH, Griffiths JR. Damage by the cracking of silicon particles in an Al–7Si–0.4Mg casting alloy. Acta Mater. 1996;44(1):25.

Wang QG, Caceres CH, Griffiths JR. Damage by eutectic particle cracking in aluminum casting alloys A356/357. Metall Mater Trans A. 2003;34(12):2901.

Jia K, Yu WB, Yao JM, Zhang S, Wu H. Al–9.00%Si–0.25%Mg alloys modified by ytterbium. Rare Met. 2017;36(2):95.

Dighe MD, Gokhale AM, Horstemeyer MF. Effect of loading condition and stress state on damage evolution of silicon particles in an Al–Si–Mg-base cast alloy. Metall Mater Trans A. 2002;33(3):555.

Beck T, Löhe D, Luft J, Henne I. Damage mechanisms of cast Al–Si–Mg alloys under superimposed thermal–mechanical fatigue and high-cycle fatigue loading. Mater Sci Eng A Struct. 2007;468(45):184.

Spencer K, Corbin SF, Lloyd DJ. The influence of iron content on the plane strain fracture behaviour of AA 5754 Al–Mg sheet alloys. Mater Sci Eng A Struct. 2002;325(1–2):394.

Emami AR, Begum S, Chen DL, Skszek T, Niu XP, Zhang Y, Gabbianelli F. Cyclic deformation behavior of a cast aluminum alloy. Mater Sci Eng A Struct. 2009;516(1):31.

Tucker MT, Horstemeyer MF, Whittington WR, Solanki KN, Gullett PM. The effect of varying strain rates and stress states on the plasticity, damage, and fracture of aluminum alloys. Mech Mater. 2010;42(10):895.

Lados DA, Apelian D, Donald JK. Fatigue crack growth mechanisms at the microstructure scale in Al–Si–Mg cast alloys: mechanisms in the near-threshold regime. Acta Mater. 2006;54(6):1475.

Chang R, Morris WL, Buck O. Fatigue crack nucleation at intermetallic particles in alloys—a dislocation pile-up model. Scr Metall Mater. 1979;13(3):191.

Morris WL. A comparison of microcrack closure load development for stage I and II cracking events for Al 7075-T651. Metall Mater Trans. 1977;8(7):1087.

Morris WL. The effect of intermetallics composition and microstructure on fatigue crack initiation in Al 2219-T851. Metall Mater Trans. 1978;9(9):1345.

Morris WL, Buck O, Marcus HL. Fatigue crack initiation and early propagation in Al 2219-T851. Metall Mater Trans. 1976;7(8):1161.

Morris WL, James MR. Statistical aspects of fatigue crack nucleation from particles. Metall Mater Trans. 1980;11(5):850.

Payne J, Welsh G Jr, Christ RJ, Nardiello J, Papazian JM. Observations of fatigue crack initiation in 7075-T651. Int J Fatigue. 2010;32(2):247.

Yeh JW, Liu WP. The cracking mechanism of silicon particles in an A357 aluminum alloy. Metall Mater Trans. 1996;27(11):3558.

Su JF, Nie X, Stoilov V. Characterization of fracture and debonding of Si particles in AlSi alloys. Mater Sci Eng A Struct. 2010;527(27–28):7168.

Gokhale AM, Dighe MD, Horstemeyer M. Effect of temperature on silicon particle damage in A356 alloy. Metall Mater Trans. 1998;29(3):905.

Gall K, Horstemeyer MF, Schilfgaarde MV, Baskes MI. Atomistic simulations on the tensile debonding of an aluminum–silicon interface. J Mech Phys Solids. 2000;48(10):2183.

Gokhale AM, Patel GR. Quantitative fractographic analysis of variability in tensile ductility of a squeeze cast Al–Si–Mg base alloy. Mater Charact. 2005;54(1):13.

Yang X, Huang X, Dai X, Campbell J, Grant RJ. Quantitative characterisation of correlations between casting defects and mechanical strength of Al–7Si–Mg alloy castings. Mater Sci Tech Lond. 2006;22(5):561.

Mohamed AMA, Samuel FH, Kahtani SA. Microstructure, tensile properties and fracture behavior of high temperature Al–Si–Mg–Cu cast alloys. Mater Sci Eng A Struct. 2013;577(577):64.

Xu XP, Needleman A. Void nucleation by inclusion debonding in a crystal matrix. Modell Simul Mater Sci Eng. 1999;1(2):111.

Needleman A. A Continuum model for void nucleation by inclusion debonding. J Appl Mech. 1987;54(3):525.

Yu QM. Influence of the stress state on void nucleation and subsequent growth around inclusion in ductile material. Int J Fract. 2015;193(1):43.

Gurland J. Observations on the fracture of cementite particles in a spheroidized 1.05% C steel deformed at room temperature. Acta Metall Metar. 1972;20(5):735–80.

Gall K, Horstemeyer M, Mcdowell DL, Fan J. Finite element analysis of the stress distributions near damaged Si particle clusters in cast Al–Si alloys. Mech Mater. 2000;32(5):277.

Acknowledgements

This study was financially supported by the National Key Research and Development Project of China (No. 2016YFC0801900).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhou, H., Zhang, Z. Evolution of silicon particle damage on fatigue crack initiation and early propagation in an aluminum alloy. Rare Met. 42, 2470–2476 (2023). https://doi.org/10.1007/s12598-017-0930-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-017-0930-9