Abstract

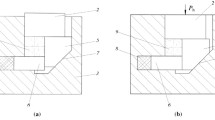

Experiments were carried out with different apparatus to compact electrolytic copper powders at distinct loading speeds. It appears that green densities of compacts prepared by HVC out-number that by conventional compaction by one percent. Compacts by quasi-static compaction are almost as dense as those by HVC under comparable peak pressure. The relationship between green compact density and peak pressure accords with Hang Pei-yun formula well. Spring-backs of HVC compacts are far smaller than those of conventional compaction and quasi-static compaction. HVC compacts are harder than compacts by conventional compaction and quasi-static compaction when they have the same density.

Similar content being viewed by others

References

Hagemeyer J W, Regalbuto J A. Dynamic compaction of metal powders with a high velocity impact device. International Journal of Powder Metallurgy, 1968, 4(3): 19–25

Wang J-X, Li X-J. Explosive consolidation of powder and its application. Powder Metallurgy Technology, 2004, 24(1): 49–54

Stein E M, Orsdel J R V, Schneider P V. High velocity compaction of iron powder. New Horizons for Powder Metallurgy, 1964, 4: 83–87

Zhou S-Y, Yin H-Q, Qu X-H. Research status of high velocity compaction technology in powder metallurgy. Materials Review, 2007, 21(7): 79–81

Chi Y, Guo S-J, Meng F, et al. High velocity compaction in powder metallurgy. Powder Metallurgy Industry, 2005, 15(6): 41–45

Shen Y-X, Xiao Z-Y, Wen L-P, et al. Principle, characteristics and status of high velocity compaction technology in powder metal-lurgy. Powder Metallurgy Industry, 2006, 16(3): 19–23

Skoglund P, Kejzelman M, Hauer I. High density PM components by high velocity compaction. Proceedings of the 2002 World Congresson Powder Metallurgy and Particulate Materials. USA: Metal Powder Industries Federation, 2002, 85–95

Skoglund P. High density PM parts by high velocity compaction. Powder Metallurgy, 2001, 44(3): 199–210

Troive L, Furuberg J, Skoglund P, et al. High density PM components by high velocity compaction, a comparison with conventional compaction. Prague, Czech Republic: Euro PM2005 Congress and Exhibition, 2–5 Oct, 2005

Andersson O. High velocity compaction of soft magnetic compo-sites. PM2TEc2001, New Orleans, USA, 2001

Eriksson M, Haggblad H A, Berggren C. New semi-isostatic high velocity compaction method to prepare titanium dental copings. Powder Metallurgy, 2004, 47(4): 335–342

Sethi G, Hauck E, German R M. High velocity compaction compared with conventional compaction. Materials Science and Technology, 2006, 22(8): 955–959

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yi, Mj., Yin, Hq., Wang, Jz. et al. Comparative research on high-velocity compaction and conventional rigid die compaction. Front. Mater. Sci. China 3, 447–451 (2009). https://doi.org/10.1007/s11706-009-0057-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11706-009-0057-5