Abstract

Ductile-to-brittle transition in a low-alloy bainitic steel used as reactor pressure vessel material coincided with the change in brittle facet plane normal(s). Experimentally, it changed from ~ {100} facets at low temperatures to off-{100} planes at the higher temperatures. And such a change was also associated with brittle-to-ductile transition in the fracture mode. Molecular dynamics simulations, however, showed that the intrinsic cleavage plane remained {100} at all temperatures. Activation of atomistic mechanisms of crack kinking and dislocation pile-up, at higher temperatures, followed by the creation of atomistic ledges at the free surface resulted in the appearance of off-{100} facets.

Similar content being viewed by others

Data Availability

The raw data required to reproduce these findings are available on request by email to the corresponding author.

Notes

This large elastic strain is due to the use of perfect crystal as a starting configuration of the simulation and is like previously reported strain values (Ref 1, 2, 22). Thus, the quantitative comparisons between simulations and experiments are avoided. Hence simulation results will be used only for providing the mechanistic explanations to the experimental results in this manuscript.

References

V.A. Borodin, P.V. Vladimirov, and A. Möslang, The Effects of Temperature on (001) <110> Crack Propagation in Bcc Iron, J. Nucl. Mater., 2013, 442(1–3), p S612–S617. https://doi.org/10.1016/j.jnucmat.2012.10.035

V.A. Borodin and P.V. Vladimirov, Three-Dimensional Atomistic Modeling of Microcrack Propagation in Iron, J. Nucl. Mater., 2011, 416(1–2), p 49–54. https://doi.org/10.1016/j.jnucmat.2010.12.224

Y. Watanabe and T. Shoji, The Evaluation of In-Service Materials Degradation of Low-Alloy Steels by the Electrochemical Method, Metall. Trans. A, 1991, 22(9), p 2097–2106

L.M. Davies, A Comparison of Western and Eastern Nuclear Reactor Pressure Vessel Steels, Int. J. Press. Vessel. Pip., 1999, 76(3), p 163–208. https://doi.org/10.1016/S0308-0161(97)00075-6

B. Gurovich, E. Kuleshova, S. Fedotova, D. Maltsev, O. Zabusov, A. Frolov, D. Erak, and D. Zhurko, Structural Mechanisms of the Flux Effect for VVER-1000 Reactor Pressure Vessel Materials, in Fontevraud 8—Contribution of Materials Investigations and Operating Experience to LWRs’ Safety, Performance and Reliability, France, Avignon—2014, September 14-18, 2014.

S. Mohanty, S. Majumdar, and K. Natesan, A Review of Stress Corrosion Cracking/Fatigue Modeling for Light Water Reactor Cooling System Components (Argonne, IL 60439, 2012).

K.H. Lee, M.J. Jhung, M.C. Kim, and B.S. Lee, Effects of Tempering and PWHT on Microstructures and Mechanical Properties of SA508 GR.4N Steel, Nucl. Eng. Technol., 2014, 46(3), p 413–422. https://doi.org/10.5516/net.07.2013.088

Y. Nishiyama, K. Onizawa, M. Suzuki, J.W. Anderegg, Y. Nagai, T. Toyama, M. Hasegawa, and J. Kameda, Effects of Neutron-Irradiation-Induced Intergranular Phosphorus Segregation and Hardening on Embrittlement in Reactor Pressure Vessel Steels, Acta Mater., 2008, 56(16), p 4510–4521. https://doi.org/10.1016/j.actamat.2008.05.026

Y.I. Shtrombakh, B.A. Gurovich, E.A. Kuleshova, A.S. Frolov, S.V. Fedotova, D.A. Zhurko, and E.V. Krikun, Effect of Ni Content on Thermal and Radiation Resistance of VVER RPV Steel, J. Nucl. Mater., 2015, 461, p 292–300. https://doi.org/10.1016/j.jnucmat.2015.02.023

O.O. Zabusov, B.A. Gurovich, E.A. Kuleshova, M.A. Saltykov, S.V. Fedotova, and A.P. Dementjev, Intergranular Embrittlement of Nuclear Reactor Pressure Vessel Steels, Key Eng. Mater., 2013, 592–593, p 577–581. https://doi.org/10.4028/www.scientific.net/KEM.592-593.577

B.A. Gurovich, E.A. Kuleshova, Y.I. Shtrombakh, O.O. Zabusov, and E.A. Krasikov, Intergranular and Intragranular Phosphorus Segregation in Russian Pressure Vessel Steels Due to Neutron Irradiation, J. Nucl. Mater., 2000, 279(2–3), p 259–272

E.A. Kuleshova, B.A. Gurovich, Y.I. Shtrombakh, D.Y. Erak, and O.V. Lavrenchuk, Comparison of Microstructural Features of Radiation Embrittlement of VVER-440 and VVER-1000 Reactor Pressure Vessel Steels, J. Nucl. Mater., 2002, 300(2–3), p 127–140

B.A. Gurovich, E.A. Kuleshova, O.V. Lavrenchuk, K. Prikhodko, and Y.I. Shtrombakh, The Principal Structural Changes Proceeding in Russian Pressure Vessel Steels as a Result of Neutron Irradiation, Recovery Annealing and Re-irradiation, J. Nucl. Mater., 1999, 264(3), p 333–353

W.R. Broughton and P.J.K. Paterson, Effect of Heat Treatment on Grain-Boundary Chemistry and Susceptibility to Embrittlement in Two Low Alloy Steels, Appl. Surf. Sci., 1983, 15, p 120–128

B.A. Gurovich, E.A. Kuleshova, Y.A. Nikolaev, and Y.I. Shtrombakh, Assessment of Relative Contributions from Different Mechanisms to Radiation Embrittlement of Reactor Pressure Vessel Steels, J. Nucl. Mater., 1997, 246(2–3), p 91–120. https://doi.org/10.1016/S0022-3115(97)00103-7

L. Debarberis, B. Acosta, A. Zeman, S. Pirfo, P. Moretto, P. Chernobaeva, and Y. Nikoleav, Evaluation of Temper Embrittlement of 30Cr2MoV Rotor Steels Using Electrochemical Impedance Spectroscopy Technique, Int. J. Microstruct. Mater. Prop., 2007, 2(3/4), p 326–338

W.R. Corwin, G.R. Odette, R.E. Stoller, and J.A. Wang, Thermal Embrittlement of Reactor Vessel Steels, in International Conference on Structural Mechanics in Reactor Technology, CONF-950804–3 (United States, 1995).

S. Druce, G. Gage, and G. Jordan, Effect of Ageing on Properties of Pressure Vessel Steels, Acta Metall., 1986, 34(4), p 641–652. https://doi.org/10.1016/0001-6160(86)90179-3

A.A. Griffith, The Phenomena of Rupture and Flow in Solids, R. Soc. Lond., 1920, 221(A-587), p 163–198

J.R. Rice and R. Thomson, Ductile Versus Brittle Behaviour of Crystals, Philos. Mag., 1974, 29(1), p 73–97

J.R. Rice, Dislocation Nucleation from a Crack Tip : An Analysis Based on the Peierls Concept, J. Mech. Phys. Solids, 1992, 40(2), p 239–271

V.A. Borodin and P.V. Vladimirov, Molecular Dynamics Simulations of Quasi-Brittle Crack Development in Iron, J. Nucl. Mater., 2011, 415(3), p 320–328. https://doi.org/10.1016/j.jnucmat.2011.04.052

M.-Y. Tu, W.-H. Wang, and Y.-F. Hsu, Crystallographic and Fractographic Analysis of Upper Bainite, Mater. Trans., 2008, 49(3), p 559–564

J.Q. Clayton and J.F. Knott, Observations of Fibrous Fracture Modes in a Prestrained Low-Alloy Steel, Met. Sci., 1976, 10, p 63–71

W.M. Garrison and N.R. Moody, Ductile Fracture, J. Phys. Chem. Solids, 1987, 48(11), p 1035–1074. https://doi.org/10.1016/0022-3697(87)90118-1

P. Gumbsch, Brittle Fracture and the Brittle-to-Ductile Transition of Tungsten, J. Nucl. Mater., 2003, 323(2–3), p 304–312

B. DeCelis, A.S. Argon, and S. Yip, Molecular Dynamics Simulation of Crack Tip Processes in Alpha-Iron and Copper, J. Appl. Phys., 1983, 54(9), p 4864–4878

S. Kohlhoff, P. Gumbsch, and H.F. Fischmeister, Crack Propagation in b.c.c. Crystals Studied with a Combined Finite-Element and Atomistic Model, Philos. Mag. A Phys. Condens. Matter. Struct. Defects Mech. Prop., 1991, 64(4), p 851–878

V. Shastry and D. Farkas, Molecular Statics Simulation of Fracture in α-Iron, Model. Simul. Mater. Sci. Eng., 1996, 4(5), p 473–492

J.J. Möller and E. Bitzek, Comparative Study of Embedded Atom Potentials for Atomistic Simulations of Fracture in α-Iron, Model. Simul. Mater. Sci. Eng., 2014, 22(4), p 045002. https://doi.org/10.1088/0965-0393/22/4/045002

J. Kim, Improvement of Impact Toughness of the SA 508 Class 3 Steel for Nuclear Pressure Vessel Through Steel-Making and Heat-Treatment Practices, Nucl. Eng. Des., 1997, 174(1), p 51–58. https://doi.org/10.1016/S0029-5493(97)00068-X

J. Fukakura, M. Asano, M. Kikuchi, and M. Ishikawa, Effect of Thermal Aging on Fracture Toughness of RPV Steel, Nucl. Eng. Des., 1993, 144(3), p 423–429

Y. Sakai, K. Tamanoi, and N. Ogura, Application of Tanh Curve Fit Analysis to Fracture Toughness Data of Japanese RPVS, Nucl. Eng. Des., 1989, 115(1), p 31–39

M.J. DeVan, I.A.L. Lowe, C.S. Wade, A.S. Kumar, D.S. Gelles, R.K. Nanstad, E.A. Little, Evaluation of Thermal-Aged Plates, Forgings, and Submerged-Arc Weld Metals, in Effects of Radiation on Materials: 16th International Symposium, ASTM STP 1175 (Philedelphia, 1993).

K.S. Cheung and S. Yip, A Molecular-Dynamics Simulation of Crack-Tip Extension: The Brittle-to-Ductile Transition, Model. Simul. Mater. Sci. Eng., 1994, 2(4), p 865–892. https://doi.org/10.1088/0965-0393/2/4/005

D. Terentyev and F. Gao, Blunting of a Brittle Crack at Grain Boundaries: An Atomistic Study in BCC Iron, Mater. Sci. Eng. A, 2013, 576, p 231–238. https://doi.org/10.1016/j.msea.2013.04.012

Y.F. Guo and Y.C. Gao, Combined Atomistic Simulation and Continuum Mechanics: Size-Dependent Behavior of Atomistic Simulation for Brittle Fracture in Bcc-Iron, Comput. Mater. Sci., 2006, 36(4), p 432–439

X. Xing, M. Yu, W. Chen, and H. Zhang, Atomistic Simulation of Hydrogen-Assisted Ductile-to-Brittle Transition in Alpha-Iron, Comput. Mater. Sci., 2017, 127, p 211–221. https://doi.org/10.1016/j.commatsci.2016.10.033

J. Prahl, A. Machová, A. Spielmannová, M. Karlík, M. Landa, P. Haušild, and P. Lejček, Ductile-Brittle Behavior at the (1 1 0)[0 0 1] Crack in Bcc Iron Crystals Loaded in Mode I, Eng. Fract. Mech., 2010, 77(2), p 184–192

Y.F. Guo and C.Y. Wang, Atomistic Study of Lattice Trapping Behavior for Brittle Fracture in Bcc-Iron, Comput. Mater. Sci., 2007, 40(3), p 376–381

B. Ma, 3D Molecular Dynamic Simulation of Fracture Behavior of Bcc Iron, in Proceedings of the 2nd International Conference on Electronic Mechanical Engineering and Information Technology (2012), pp. 2263–2266. https://doi.org/10.2991/emeit.2012.501.

M. Mendelev, S. Han, D. Srolovitz, G. Acklnad, D. Sun, and M. Asta, Development of New Interatomic Potentials Appropriate for Crystalline and Liquid Iron, Philos. Mag., 2003, 83, p 3977–3994

X.W. Zhou, J.A. Zimmerman, E.D. Reedy, and N.R. Moody, Molecular Dynamics Simulation Based Cohesive Surface Representation of Mixed Mode Fracture, Mech. Mater., 2008, 40(10), p 832–845

A. Uhnáková, J. Pokluda, A. MacHová, and P. Hora, 3D Atomistic Simulation of Fatigue Behavior of a Ductile Crack in Bcc Iron Loaded in Mode II, Comput. Mater. Sci., 2012, 61, p 12–19

A. Uhnáková, J. Pokluda, A. MacHová, and P. Hora, 3D Atomistic Simulation of Fatigue Behaviour of Cracked Single Crystal of Bcc Iron Loaded in Mode III, Int. J. Fatigue, 2011, 33(12), p 1564–1573

A. Uhnáková, A. MacHová, and P. Hora, 3D Atomistic Simulation of Fatigue Behavior of a Ductile Crack in Bcc Iron, Int. J. Fatigue, 2011, 33(9), p 1182–1188

A. Machová, J. Pokluda, A. Uhnáková, and P. Hora, 3D Atomistic Studies of Fatigue Behaviour of Edge Crack (0 0 1) in Bcc Iron Loaded in Mode I, and II, Int. J. Fatigue, 2014, 66, p 11–19

A. Uhnáková, A. MacHová, P. Hora, J. Červ, and T. Kroupa, Stress Wave Radiation from the Cleavage Crack Extension in 3D Bcc Iron Crystals, Comput. Mater. Sci., 2010, 50(2), p 678–685

T. Liu and M.S. Liu, Atomistic Simulation of Fatigue Crack Growth in α-Fe Under High Temperature, Appl. Mech. Mater., 2015, 750, p 226–235. https://doi.org/10.4028/www.scientific.net/AMM.750.226

R.E. Roman and S.W. Cranford, Mechanical Properties of Silicene, Comput. Mater. Sci., 2014, 82, p 50–55. https://doi.org/10.1016/j.commatsci.2013.09.030

S. Shao, H.M. Zbib, I.N. Mastorakos, and D.F. Bahr, The Void Nucleation Strengths of the Cu-Ni-Nb-Based Nanoscale Metallic Multilayers Under High Strain Rate Tensile Loadings, Comput. Mater. Sci., 2014, 82, p 435–441. https://doi.org/10.1016/j.commatsci.2013.09.036

K. Zhao, I. Gudem Ringdalen, J. Wu, J. He, and Z. Zhang, Ductile Mechanisms of Metals Containing Pre-existing Nanovoids, Comput. Mater. Sci., 2016, 125(October 2017), p 36–50

M.Q. Le and R.C. Batra, Crack Propagation in Pre-strained Single Layer Graphene Sheets, Comput. Mater. Sci., 2014, 84, p 238–243. https://doi.org/10.1016/j.commatsci.2013.12.007

Z. Zhao and F. Chu, Molecular Dynamics Simulation of Crack Initiation and Propagation in Bcc Iron Under Load Within Spur Gear Tooth Root, Fatigue Fract. Eng. Mater. Struct., 2018, 41(2), p 323–335

J. Zhang, Molecular Dynamics Study of Crack Propagation Behavior and Mechanisms in Nickel, The Ohio State University, Ohio, 2011

T. Liu and M. Liu, Atomistic Simulation of Fatigue Crack Growth in α-Fe under High Temperature, In 13th International Conference on Fracture (Beijing, China, 2013), pp. 1–11.

J.J. Möller and E. Bitzek, On the Influence of Crack Front Curvature on the Fracture Behavior of Nanoscale Cracks, Eng. Fract. Mech., 2015, 150, p 197–208

A. Stukowski, Visualization and Analysis of Atomistic Simulation Data with OVITO–the Open Visualization Tool, Model. Simul. Mater. Sci. Eng., 2010, 18(1), p 15012

A. Scheid, L.M. Félix, D. Martinazzi, T. Renck, and C.E. Fortis Kwietniewski, The Microstructure Effect on the Fracture Toughness of Ferritic Ni-Alloyed Steels, Mater. Sci. Eng. A, 2016, 661, p 96–104. https://doi.org/10.1016/j.msea.2016.03.019

A.V. Nikolaeva, Y.A. Nikolaev, and A.M. Kryukov, The Contribution of Grain Boundary Effects to Low-Alloy Steel Irradiation Embrittlement, J. Nucl. Mater., 1995, 218(1), p 85–93

J. Li, C. Zhang, and Y. Liu, Influence of Carbides on the High-Temperature Tempered Martensite Embrittlement of Martensitic Heat-Resistant Steels, Mater. Sci. Eng. A, 2016, 670, p 256–263. https://doi.org/10.1016/j.msea.2016.06.025

K.H. Lee, M.C. Kim, W.J. Yang, and B.S. Lee, Evaluation of Microstructural Parameters Controlling Cleavage Fracture Toughness in Mn-Mo-Ni Low Alloy Steels, Mater. Sci. Eng. A, 2013, 565, p 158–164. https://doi.org/10.1016/j.msea.2012.12.024

R.H. Dauskardt, R.D. Pendse, and R.O. Ritchie, Effects of Pre-existing Grain Boundary Microvoid Distributions on Fracture Toughness and Fatigue Crack Growth in Low Alloy Steel, Acta Metall., 1987, 35(9), p 2227–2242

P. Bowen, S.G. Druce, and J.F. Knott, Effects of Microstructure on Cleavage Fracture in Pressure Vessel Steel, Acta Metall., 1986, 34(6), p 1121–1131. https://doi.org/10.1016/0001-6160(86)90222-1

W.D. Biggs and P.L. Pratt, The Deformation and Fracture of Alpha-Iron at Low Temperatures, Acta Metall., 1958, 6(11), p 694–703

D. Hull, Twining and Fracture of Single Crystals of 3% Silicon Iron, Acta Metall., 1960, 8, p 11–18

R. Honda, Cleavage Fracture in Single Crystals of Silicon Iron, J. Phys. Soc. Jpn., 1961, 16(7), p 1309–1321

Y.F. Guo and D.L. Zhao, Atomistic Simulation of Structure Evolution at a Crack Tip in Bcc-Iron, Mater. Sci. Eng. A, 2007, 448(1–2), p 281–286. https://doi.org/10.1016/j.msea.2006.10.033

I.R. Vatne, E. Østby, and C. Thaulow, Multiscale Simulations of Mixed-Mode Fracture in Bcc-Fe, Model. Simul. Mater. Sci. Eng., 2011, 19(8), p 1–18. https://doi.org/10.1088/0965-0393/19/8/085006

A.S. Tetelman and W.D. Robertson, Direct Observation and Analysis of Crack Propagation in Iron-3 Percent Silicon Single Crystals, Acta Metall., 1963, 11, p 415–425. https://doi.org/10.1016/0001-6160(63)90166-4

M. Allen, Introduction to Molecular Dynamics Simulation, Computational Soft Matter: From Synthetic Polymers to Proteins, NIC Series, Vol. 23, John von Neumann Institute for Computing, 2004, p 1–28. http://www.fzj.helmholtz.de/nic-series/volume23/allen.pdf

F.F. Abraham, D. Brodbeck, W.E. Rudge, and X. Xu, A Molecular Dynamics Investigation of Rapid Fracture Mechanics, J. Mech. Phys. Solids, 1997, 45(9), p 1595–1619

L. Ma, S. Xiao, H. Deng, and W. Hu, Molecular Dynamics Simulation of Fatigue Crack Propagation in Bcc Iron Under Cyclic Loading, Int. J. Fatigue, 2014, 68, p 253–259. https://doi.org/10.1016/j.ijfatigue.2014.04.010

E. Bitzek, J.R. Kermode, and P. Gumbsch, Atomistic Aspects of Fracture, Int. J. Fract., 2015, 191(1–2), p 13–30

G. Sainath, B.K. Choudhary, and T. Jayakumar, Molecular Dynamics Simulation Studies on the Size Dependent Tensile Deformation and Fracture Behaviour of Body Centred Cubic Iron Nanowires, Comput. Mater. Sci., 2015, 104, p 76–83. https://doi.org/10.1016/j.commatsci.2015.03.053

S.P. Ju, J. Sen Lin, H.L. Chen, J.Y. Hsieh, H.T. Chen, M.H. Weng, J.J. Zhao, L.Z. Liu, and M.C. Chen, A Molecular Dynamics Study of the Mechanical Properties of a Double-Walled Carbon Nanocoil, Comput. Mater. Sci., 2014, 82, p 92–99. https://doi.org/10.1016/j.commatsci.2013.09.024

F. Calvo, Molecular Dynamics Determination of the Surface Tension of Silver-Gold Liquid Alloys and the Tolman Length of Nanoalloys, J. Chem. Phys., 2012, 136(15), p 154701

O.K. Kwon, H.J. Hwang, and J.W. Kang, Molecular Dynamics Simulation Study on Cross-Type Graphene Resonator, Comput. Mater. Sci., 2014, 82, p 280–285. https://doi.org/10.1016/j.commatsci.2013.09.053

X. Ou, Molecular Dynamics Simulations of Fcc-to-Bcc Transformation in Pure Iron: A Review, Mater. Sci. Technol. U. K., 2017, 33(7), p 822–835

H. Akbarzadeh, H. Abroshan, and G.A. Parsafar, Surface Free Energy of Platinum Nanoparticles at Zero Pressure: A Molecular Dynamic Study, Solid State Commun., 2010, 150(5–6), p 254–257. https://doi.org/10.1016/j.ssc.2009.11.013

J. Shi, L. Peng, M. Ye, Defect Effects on Grain Boundary Strength in Fe: A Molecular Dynamics Simulation*, in IEEE 26th Symposium on Fusion Engineering IEEE 26th Symposium on Fusion Engineering (Austin, TX, USA, IEEE, 2015), pp. 1–4.

D.P. Field, Recent Advances in the Application of Orientation Imaging, Ultramicroscopy, 1997, 67(1–4), p 1–9

S.I. Wright, M.M. Nowell, S.P. Lindeman, P.P. Camus, M. De Graef, and M.A. Jackson, Introduction and Comparison of New EBSD Post-processing Methodologies, Ultramicroscopy, 2015, 159(P1), p 81–94. https://doi.org/10.1016/j.ultramic.2015.08.001

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix

Appendix

EBSD of Fracture Surface for Determination of the Cleavage Facet Orientation

One of the principle limitations in employing the EBSD on fractured samples with facets (characteristic of brittle cleavage regions) is the unknown value of the sample’s local surface inclination with the incident electron beam. This angle is termed as tilt angle. Since the fractured facets can have arbitrary facet orientations, majority of the time the facet inclination is not supportive for the recording good quality Kikuchi patterns. Additionally, there can be shadow effect of other intervening facets. However, statistically some facets can have their surface inclination near the desirable value of ~ 70° from the incident beam. They can give rise to the solvable Kikuchi patterns. These patterns are hence amenable for orientation determination by EBSD with the assumption of surface being at 70° tilt to the incident beam. Any such measurement would, however, be associated with ‘error’. This ‘error’ was quantified in terms of two commonly known EBSD solution parameters: Confidence Index (CI) and Fit (Ref 82, 83).

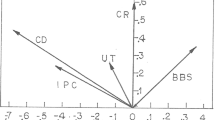

The ‘error’ estimation involved an exercise similar in principle as the one proposed by David Field (Ref 82). As shown in Fig. 12, 400 × 400 micron scans were taken at different tilt angles: 60°-74°, and at 2° steps. CI and Fit values were estimated from such scans. As shown in Fig. 12, they showed the highest CI or lowest fit at 70° ± 2°. It was hence proposed that if measurement (albeit manual) of a faceted (and unpolished) surface had the highest CI (~ 0.9) and lowest fit (~ 0.1), then ‘error’ in orientation estimation is limited to ± 2°. The measurements presented in Fig. 4 are thus expected to have a measurement uncertainty of ± 2°.

The variation in the average confidence index (CI) and fit as a function of tilt angle. The data were generated from 400 × 400 micron scans of the typical martensitic structure (as in Fig. 2) of the Mn-Ni-Mo steel. Highest CI and lowest fit were obtained at 70° ± 2° of the tilt angle (color online)

Rights and permissions

About this article

Cite this article

Sharma, T., Kumar, N.N., Mondal, R. et al. Ductile-to-Brittle Transition in Low-Alloy Steel: A Combined Experimental and Numerical Investigation. J. of Materi Eng and Perform 28, 4275–4288 (2019). https://doi.org/10.1007/s11665-019-04173-1

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-019-04173-1