Abstract

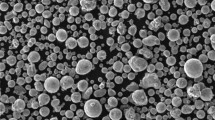

The direct manufacture of metal parts by rapid prototyping (RP) often involves using a metal powder. Densification of the powder can be done either by sintering or infiltration. Infiltration avoids the shrinkage and distortion that typically accompanies sintering. However, in steels, the use of copper or bronze infiltrants limits the usefulness of parts because of the nonhomogeneous structure and properties. In this work, a conventional tool steel alloy has been made via homogeneous steel infiltration (HSI), a gated infiltration process that uses as the infiltrant a steel alloy with a lower melting point than the base powder. The infiltrant liquid uses carbon or silicon as a melting point depressant (MPD). Freeze-off of the steel infiltrant is avoided by infiltrating at a temperature at which some liquid is stable at chemical equilibrium. Examples of successful infiltrations using D2 tool steel as a target composition are shown. Mechanical properties (hardness and impact strength) following various heat treatments of the infiltrated D2 are compared with conventional wrought D2 tool steel and found to be very similar. The HSI is believed to be suitable to a wide variety of tool steels and stainless steels. Further, the process is applicable to the postprocessing of any suitable steel skeleton made by RP, as well as other powder metallurgy processes, such as metal injection molding.

Similar content being viewed by others

References

E. Sachs, P. Williams, D. Brancazio, M. Cima, and K. Kremmin: Proc. Manufacturing Int. ’90, ASME, New York, NY, 1990, vol. 4, pp. 131–36.

S. Michaels, E. Sachs, and M. Cima: Solid Freeform Fabrication Symp. 1992, University of Texas, Austin, TX, 1992, pp. 244–50.

J. Lembo: Adv. Mater. Processes, 2003, vol. 161, pp. 52–53.

E. Goode: Adv. Mater. Processes, 2003, vol. 161, pp. 66–67.

D.F. Heaney and R.M. German: Adv. Powder Metall. Part Mater., MPIF, Princeton, NJ, 2001, pp. 8.73–8.83.

R. Irving: Int. J. Powder Metall., 2000, vol. 36, pp. 69–74.

E. Sachs, E. Wylonis, M. Cima, S. Allen, S. Michaels, E. Sun, H. Tang, and H. Guo: ANTEC ’95, Vol. I—Processing, Society of Plastic Engineers, Brookfield, CT, 1995, pp. 997–1003.

B.K. Paul, and S. Baskaran: J. Mater. Proc. Technol., 1996, vol. 61, pp. 168–72.

E. Radstok: Rap. Prototyping J., 1999, vol. 5, pp. 164–68.

S.S. Dimov, D.T. Pham, F. Lacan, and K.D. Dotchev: Assembly Automation, 2001, vol. 21, pp. 296–302.

T.D. Stewart, K.W. Dalgarno, T.H.C. Childs, and J. Perkins: Solid Freeform Fabrication Symp., University of Texas, Austin, TX, 1999, pp. 443–49.

D. Uzunsoy, I.T.H. Chang, and P. Bowen: Powder Metall., 2002, vol. 45, pp. 251–54.

S. Banerjee, R. Oberacker, and C.G. Goetzel: Int. J. Powder Metall. Powder Technol., 1984, vol. 20, pp. 325–41.

S. Banerjee, R. Oberacker, and C.G. Goetzel: Modern Developments in Powder Metallurgy, 1985, vol. 16, pp. 209–44.

A. Lorenz, E. Sachs, S. Allen, L. Rafflenbeul, and B. Kernan: Metall. Mater. Trans. A, 2004, vol. 35A, pp. 631–40.

A. Lorenz, E. Sachs, and S. Allen: Metall. Mater. Trans. A., 2004, vol. 35A, pp. 641–53.

G. Langord: Mater. Sci. Eng., 1977, vol. 28, pp. 275–84.

G. Langford and R.E. Cunningham: Metall. Trans. B, 1978, vol. 9B, pp. 5–19.

T.B. Sercombe, M. Loretto, and X. Wu: Powder Metallurgy and Particulate Materials, Metal Powder Industries Federation, New York, NY, 2000, pp. 3-25–3-36.

K.A. Thorsen, S. Hansen, and O. Kjaergaard: Powder Metall. Int., 1983, vol. 15, pp. 91–93.

CALPHAD and Alloy Thermodynamics, P.E.A. Turchi, A. Gonis, and R.D. Shull, eds., TMS, Warrendale, PA, 2002.

M. Hillert: Scand. J. Metall., 1997, vol. 26, pp. 215–23.

M. Hillert: Iron Steel Inst. Jpn. Int., 1990, vol. 30, pp. 559–66.

ASM Handbook, 10th ed., ASM INTERNATIONAL, Materials Park, OH, 1990, vol. 1, pp. 758 and 909.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Kernan, B.D., Sachs, E.M., Allen, S.M. et al. Homogeneous steel infiltration. Metall Mater Trans A 36, 2815–2827 (2005). https://doi.org/10.1007/s11661-005-0278-x

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11661-005-0278-x