Abstract

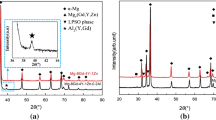

The effects of Sn and Ga additions on the glass forming ability (GFA) of (Al86La5Ni9)100−x Sn x (x=0, 0.2, 0.3, 0.5, 0.7, 1 and 2 at.%) and (Al86La5Ni9)100−x Ga x (x=0, 0.2, 0.5, 1 and 1.5 at.%) alloys were systematically investigated. Unlike common microalloying methods, both Sn and Ga have a positive heat of mixing with the main component of Al. Our analysis confirmed that proper Sn addition can suppress the strong formation of α-Al and enhance the GFA due to the positive heat of mixing between Sn and Al and the large difference in their atomic sizes. While the addition of Ga to the base alloy acted as the nucleation cites for α-Al and accelerated precipitation of the α-Al phase, thus deteriorating the GFA.

Similar content being viewed by others

References

Inoue A. Amorphous, nanoquasicrystalline and nanocrystalline alloys in Al-based systems. Prog Mater Sci, 1998, 43: 365–520

He Y, Poon S J, Shiflet G J. Synthesis and properties of metallic glasses that contain aluminum. Science, 1988, 241: 1640–1642

Yang H, Wang J Q, Li Y. Influence of TM and RE elements on glass formation of the ternary Al-TM-RE systems. J Non-Cryst Solids, 2008, 354: 3473–3479

Wu N C, Kan D, Zuo L, et al. Efficient atomic packing-chemistry coupled model and glass formation formation in ternary Al-based metallic glasses. Intermetallics, 2013, 39: 1–4

Sheng H W, Cheng Y Q, Lee P L, et al. Atomic packing in multicomponent aluminum-based metallic glasses. Acta Mater, 2008, 56: 6264–6272

Yang B J, Yao J H, Zhang J, et al. Al-rich bulk metallic glasses with plasticity and ultrahigh specific strength. Scripta Mater, 2009, 61: 423–426

Zhuo L C, Pang S J, Wang H, et al. Ductile bulk Aluminum-based alloys with good glass-forming ability and high strength. Chin Phys Lett, 2009, 26: 066402

Greer A L. Metallic glasses. Science, 1995, 267: 1947–1953

Miracle D B. A structure model for metallic glasses. Nat Mater, 2004, 3: 697–702

Poon S J, Shiflet G J, Guo F Q, et al. Glass formability of ferrous- and aluminum-based structural metallic alloys. J Non-Cryst Solids, 2003, 317: 1–9

Angell C A. Formation of glasses from liquids and biopolymers. Science, 1995, 267: 1924–1935

Inoue A. Stabilization of metallic supercooled liquid and bulk amorphous alloys. Acta Mater, 2000, 48: 279–306

Greer A L. Confusion by design. Nature, 1993, 366: 303–304

Turnbull D. Under what condition can a glass be formed. Contemp Phys, 1969, 10: 473–488

Wang W H. Roles of minor additions in formation and properties of bulk metallic glasses. Prog Mater Sci, 2007, 52: 540–596

Liu C T, Lu Z P. Effect of minor alloying addition on glass formation in bulk metallic glasses. Intermetallics, 2005, 13: 415–418

Zhang B, Wang R J, Zhao D Q, et al. Superiorglass-forming ability through microalloying in cerium-based alloys. Phys Rev B, 2006, 73: 092201

Lu Z P, Liu C T, Thompson J R, et al. Structural amorphous steels. Phys Rev Lett, 2004, 92: 245503

Lu Z P, Liu C T, Poter W D. Role of yttrium in glass formation of Fe-based bulk metallic glasses. Appl Phys Lett, 2003, 83: 2581–2583

Kundig A A, Lepori D, Perry A J, et al. Influence of low oxygen contents and alloy refinement on the glass forming ability of Zr52.5Cu17.9Ni14.6Al10Ti5. Mater Trans, 2002, 43: 3206–3210

Wang J Q, Liu Y H, Imhoff S, et al. Enhance the thermal stability and glass forming ability of Al-based metallic glass by Ca minor-alloying. Intermetallics, 2012, 29: 35–40

Li G H, Bian X F, Song K K, et al. Effect of Si addition on glass forming ability and thermal stability of Al-Fe-La alloys. J Alloys Compd, 2009, 471: L47–L50

Chen Z P, Gao J E, Wu Y, et al. Role of rare-earth elements in glass formation of Al-Ca-Ni amorphous alloys. J Alloys Compd, 2012, 513: 387–392

Jiao Z B, Li H X, Gao J E, et al. Effects of alloying elements on glass formation, mechanical and soft-magnetic properties of Fe-based metallic glasses. Intermetallics, 2011, 19: 1502–1508

Xia J, Qiang J, Wang Y, et al. Ternary bulk metallic glasses formed by minor alloying of Cu8Zr5 icosahedron. Appl Phys Lett, 2006, 88: 101907

Sanders W S, Warner J S, Miracle D B. Stability of Al-rich glasses in the Al-La-Ni system. Intermetallics, 2006, 14: 348–351

Huang Z H, Li J F, Rao Q L, et al. Effects of La content on the glass transition and crystallization process of Al-La-Ni amorphous alloys. Intermetallics, 2007, 15: 1139–1146

Mirkovié D, Gröbner J, Schmid-Fetzer R. Liquid demixing and microstructure formation in ternary Al-Sn-Cu alloys. Mater Sci Eng A, 2008, 487: 456–467

Lu Z P, Ma D, Liu C T, et al. Competitive formation of glasses and glass-matrix composites. Intermetallics, 2007, 15: 253–259

Takeuchi A, Inoue A. Classiication of bulk metallic glasses by atomic size difference, heat of mixing and period of constituent elements and its application to characterization of the main alloying element. Mater Trans, 2005, 46: 2817–2829

ASM Handbook Committee. ASM Handbook. Volume 3 Alloy Phase Diagrams. Ohio: Metals Park, 1992. 1–1741

Senkov O N, Miracle D B. Effect of the atomic size distribution on glass forming ability of amorphous metallic alloys. Mater Res Bull, 2001, 36: 2183–2198

Lu Z P, Liu C T. A new glass-forming ability criterion for bulk metallic glasses. Acta Mater, 2002, 50: 3501–3512

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chen, Z., Gao, J., Wu, Y. et al. Alloying effects of the elements with a positive heat of mixing on the glass forming ability of Al-La-Ni amorphous alloys. Sci. China Phys. Mech. Astron. 57, 122–127 (2014). https://doi.org/10.1007/s11433-013-5253-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11433-013-5253-8