Abstract

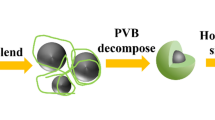

15vol%SiCp/Al–Cu–Mg composites were fabricated by hot pressing method using pure elemental powders. Microstructure evolution and elemental diffusion of Cu and Mg were studied. The microstructure of as-hot pressed composites and the elemental distribution of the composites before and after solution treatment were also investigated. The results showed that there were two types of eutectic liquid phases with different compositions after the compact was heated to 580 °C. After the compact was held at 580 °C for 60 min, the eutectic liquid was absorbed into the Al matrix and some equilibrium liquid phases formed in the boundaries of the initial Al particles. Meanwhile, Cu was homogeneously distributed in the Al particles while Mg tended to be distributed near the boundaries of the initial Al particles and in the SiC clusters. The presence of Al2Cu, Mg2Si, and some oxides of Mg was identified in the as-hot pressed composite. After solution treatment, Al2Cu dissolved into the Al matrix, however, some Mg-rich compounds (silicide and oxide of Mg) did not dissolve into the matrix completely.

Similar content being viewed by others

References

Miracle DB (2005) Compos Sci Technol 65:2526

Rosso M (2006) J Mater Proc Technol 175:364

Lloyd DJ (1994) Int Mater Rev 39:1

Shang JK, Ritchie RO (1989) Acta Metall 37:2267

Davidson DL (1989) J Mater Sci 24:681. doi:https://doi.org/10.1007/BF01107459

Srivatsan TS, Hajri MA, Smith C, Petraroli M (2003) Mater Sci Eng A 346:91

Appendino P, Badini C (1991) Mater Sci Eng A 135:275

Singh PM, Lewandowski JJ (1993) Metall Trans A 24:2531

Kim SC, Kim MT, Lee S, Chung H, Ahn JH (2005) J Mater Sci 40:441. doi:https://doi.org/10.1007/s10853-005-6101-7

Zhou J, Duszczyk J (1999) J Mater Sci 34:545. doi:https://doi.org/10.1023/A:1004594628862

Ogel B, Gurbuz R (2001) Mater Sci Eng A 301:213

Mondolfo LF (1976) Aluminium alloys: structure and properties. Butterworth & Co. Ltd., London

Schaffer GB, Sercombe TB, Lumley RN (2001) Mater Chem Phys 67:85

Zhu M, Ouyang LZ, Wu ZF, Zeng MQ, Li YY, Zou J (2006) Mater Sci Eng A 434:352

Liu ZY, Sercombe TB, Schaffer GB (2007) Metall Mater Trans A 38:1351

Song M, He YH (2010) Mater Des 31:985

Tang F, Anderson IE, Biner SB (2002) J Light Metals 2:201

Kimura A, Shibata M, Kondoh K, Takeda Y, Katayama M, Kanie T, Takada H (1997) Appl Phys Lett 70:3615

Strangwood M, Hippsley CA, Lewandowski JJ (1990) Scr Metall Mater 24:1483

Nutt SR, Carpenter RW (1985) Mate Sci Eng 75:169

Kiourtsidis GE, Skoliano SM, Litsardakis GA (2004) Mater Sci Eng A 382:351

Urena A, Martinez EE, Rodrigo P, Gil L (2004) Compos Sci Technol 64:1843

Rodrigo P, Poza P, Utrilla V, Urena A (2009) J Alloy Compd 479:451

Slipenyuk A, Kuprin V, Milman Y, Goncharuk V, Eckert J (2006) Acta Mater 54:157

Mcleod AD, Gabrye CM (1992) Metall Trans A 23:1279

Ma ZY, Lu YX, Luo M, Bi J (1995) J Mater Sci Technol 11:291

Thomas MP, King JE (1996) Compos Sci Technol 56:1141

Jin P, Xiao BL, Wang QZ, Ma ZY, Liu Y, Li S (2011) Mater Sci Eng A 528:1504

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, Q., Xiao, B.L., Liu, Z.Y. et al. Microstructure evolution and elemental diffusion of SiCp/Al–Cu–Mg composites prepared from elemental powder during hot pressing. J Mater Sci 46, 6783–6793 (2011). https://doi.org/10.1007/s10853-011-5636-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-011-5636-z