Abstract

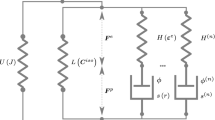

This paper presents the formulation of a constitutive model for amorphous thermoplastics using a thermodynamic approach with physically motivated internal state variables. The formulation follows current internal state variable methodologies used for metals and departs from the spring-dashpot representation generally used to characterize the mechanical behavior of polymers like those used by Ames et al. in Int J Plast, 25, 1495–1539 (2009) and Anand and Gurtin in Int J Solids Struct, 40, 1465–1487 (2003), Anand and Ames in Int J Plast, 22, 1123–1170 (2006), Anand et al. in Int J Plast, 25, 1474–1494 (2009). The selection of internal state variables was guided by a hierarchical multiscale modeling approach that bridged deformation mechanisms from the molecular dynamics scale (coarse grain model) to the continuum level. The model equations were developed within a large deformation kinematics and thermodynamics framework where the hardening behavior at large strains was captured using a kinematic-type hardening variable with two possible evolution laws: a current method based on hyperelasticity theory and an alternate method whereby kinematic hardening depends on chain stretching and material plastic flow. The three-dimensional equations were then reduced to the one-dimensional case to quantify the material parameters from monotonic compression test data at different applied strain rates. To illustrate the generalized nature of the constitutive model, material parameters were determined for four different amorphous polymers: polycarbonate, poly(methylmethacrylate), polystyrene, and poly(2,6-dimethyl-1,4-phenylene oxide). This model captures the complex character of the stress–strain behavior of these amorphous polymers for a range of strain rates.

Similar content being viewed by others

References

Ahzi S., Makradi A., Gregory R.V., Edie D.D.: Modeling of deformation behavior and strain-induced crystallization in poly(ethylene terephthalate) above the glass transition temperature. Mech. Mater. 35, 1139–1148 (2003)

Anand L.: On H. Hencky’s approximate strain-energy function for moderate deformations. ASME J. Appl. Mech. 46, 78–82 (1979)

Anand L.: Moderate deformations in extension–torsion of incompressible isotropic elastic materials. J. Mech. Phys. Solids 34, 293–304 (1986)

Anand L., Gu C.: Granular materials: constitutive equations and strain localization. J. Mech. Phys. Solids 48, 1710–1733 (2000)

Anand L., Gurtin M.E.: A theory of amorphous solids undergoing large deformations, with application to polymeric glasses. Int. J. Solids Struct. 40, 1465–1487 (2003)

Anand L., Ames N.M.: On modeling the micro-indentation response of an amorphous polymer. Int. J. Plast. 22, 1123–1170 (2006)

Anand L., Ames N.M., Srivastava V., Chester S.A.: A thermo-mechanically coupled theory for large deformations of amorphous polymers. Part I: formulation. Int. J. Plast. 25, 1474–1494 (2009)

Ames N.M., Srivastava V., Chester S.A., Anand L.: A thermo-mechanically coupled theory for large deformations of amorphous polymers. Part II: applications. Int. J. Plast. 25, 1495–1539 (2009)

Argon A.S.: A theory for the low temperature plastic deformation of glassy polymers. Philos. Mag. 28, 839–865 (1973)

Arruda E.M., Boyce M.C.: Evolution of plastic anisotropy in amorphous polymers during finite straining. Int. J. Plast. 9, 697–720 (1993)

Arruda E.M., Boyce M.C., Jayachandran R.: Effects of strain rate, temperature and thermomechanical coupling on the finite strain deformation of glassy polymers. Mech. Mater. 19, 193–212 (1995)

Bammann D.J.: Internal variable model of viscoplasticity. Int. J. Eng. Sci. 22, 1041–1053 (1984)

Bammann D.J.: Modeling temperature and strain rate dependent large deformations of metals. Appl. Mech. Rev. 1, 312–318 (1990)

Bamman D.J., Chiesa M.L., Johnson G.C.: Modeling large deformation and failure in manufacturing processes. In: Tatsumi, T., Wanatabe, E., Kambe, T. (eds) Theoretical and Applied Mechanics, pp. 359–376. Elsevier Science, USA (1996)

Bardenhagen S.G., Stout M.G., Gray G.T.: Three-dimensional finite deformation viscoplastic constitutive models for polymeric materials. Mech. Mater. 25, 235–253 (1997)

Bouvard, J.L., Ward, D.K., Hossain, D., Nouranian, S., Marin, E.B., Horstemeyer, M.F.: Review of hierarchical multiscale modeling to describe the mechanical behavior of amorphous polymers. JEMT. doi:10.1115/1.3183779 (2009)

Bouvard, J.L., Bouvard, C., Tyson, M., Fletcher, S., Tucker, M., Wang, P.: Model for predicting the strain rate dependence-Impact performance of plastic components: phase I, CAVS Report MSU.CAVS.CMD.2009-R0020 (2009)

Boyce M.C., Parks D.M., Argon A.S.: Large inelastic deformation of glassy deformation of glassy polymers part I : rate dependent constitutive model. Mech. Mater. 7, 15–33 (1988)

Boyce M.C., Weber G.G., Parks D.M.: On the kinematics of finite strain plasticity. J. Mech. Phys. Solids 37, 647–665 (1989)

Christensen R.M.: Theory of Viscoelasticty: an Introduction. Academic Press, New York (1982)

Coleman B., Gurtin M.: Thermodynamics with internal state variables. J. Chem. Phys. 47, 597–613 (1967)

Elias-Zuniga A., Beatty M.F.: Constitutive equations for amended non-Gaussian network models of rubber elasticity. Int. J. Eng. Sci. 40, 2265–2294 (2002)

Eyring H.: Viscosity, plasticity, and diffusion as examples of absolute reaction rates. J. Chem. Phys. 4, 283–291 (1936)

Fotheringham D.G., Cherry B.W.: Comment on the compression yield behaviour of polymethyl methacrylate over a wide range of temperatures and strain-rates. J. Mater. Sci. 11, 1368–1370 (1976)

Fotheringham D.G., Cherry B.W.: The role of recovery forces in the deformation of linear polyethylene. J. Mater. Sci. 13, 951–964 (1978)

Gent A.N.: A new constitutive relation for rubber. Rubber Chem. Technol. 69, 59–61 (1996)

Ghorbel E.: A viscoplastic constitutive model for polymeric material. Int. J. Plast. 24, 2032–2058 (2008)

Govaert L.E., Timmermans P.H.M., Brekelmans W.A.M.: The influence of intrinsic strain softening on strain localization in polycarbonate: modeling and experimental validation. J. Eng. Mater. Technol. 122, 177–185 (2000)

Gurtin M.: An Introduction to Continuum Mechanics. Academic Press, New York (1981)

Gurtin M.E., Anand L.: The decomposition F = FeFp, material symmetry, and plastic irrotationality for solids that are isotropic-viscoplastic or amorphous. Int. J. Plast. 21, 1686–1719 (2005)

Hasan O.A., Boyce M.C.: A constitutive model for the nonlinear viscoelastic viscoplastic behavior of glassy polymers. Polym. Eng. Sci. 35, 331–344 (1995)

Haupt P., Lion A., Bachaus E.: On the dynamic behaviour of polymers under finite strains: constitutive modelling and identification of parameters. Int. J. Solids Struct. 37, 3633–3646 (2000)

Haward, R.N., Thackray, G.: The use of a mathematical model to describe isothermal stress–strain curves in glassy thermoplastics. In: Proceedings of the Royal Society of London, vol. 302, pp. 453–472 (1968)

Hencky H.: The elastic behavior of vulcanized rubber. J. Appl. Mech. 1, 45–53 (1933)

Holzapfel G.A., Simo J.C.: A new viscoelastic constitutive model for continuous media at finite thermomechanical changes. Int. J. Solids Struct. 33, 3019–3034 (1996)

Hossein, D., Ward, D.K., Bouvard, J.L., Horstemeyer, M.F.: Atomistic Exploration of Amorphous Glassy Polymers. CAVS Internal Report (2009)

Hoy, R.S., Robbins, M.O.: Strain hardening of polymer glasses: limitations of network models. Phys. Rev. Lett. doi:10.1103/PhysRevLett.99.117801 (2007)

Hoy R.S., Robbins M.O.: Strain hardening of polymer glasses: entanglements, energetics, and plasticity. Phys. Rev. E 77, 031801 (2008)

Hoover W.G.: Canonical dynamics: equilibrium phase-space distributions. Phys. Rev., A31, 1695–1697 (1985)

James H.M., Guth E.: Theory of elastic properties of rubber. J. Chem. Phys. 11, 455–481 (1943)

Khan A.S., Zhang H.: Finite deformation of a polymer and constitutive modeling. Int. J. Plast. 17, 1167–1188 (2001)

Khan A.S., Lopez-Pamies O., Kazmi R.: Thermo-mechanical large deformation response and constitutive modeling of viscoelastic polymers over a wide range of strain rates and temperatures. Int. J. Plast. 22, 581–601 (2006)

Krempl E.: The overstress dependence of the inelastic rate of deformation inferred from transient tests. Mater. Sci. Res. Int. 1, 3–10 (1995)

Krempl E.: A small strain viscoplasticity theory based on overstress. In: Krausz, A., Krausz, K. (eds) Unified Constitutive Laws of Plastic Deformation, pp. 281–318. Academic Press, San Diego (1996)

Krempl E., Ho K.: An overstress model for solid polymer deformation behavior applied to Nylon 66. ASTM STP 1357, 118–137 (2000)

Krempl E., Khan F.: Rate (time)-dependent deformation behavior: an overview of some properties of metals and solid polymers. Int. J. Plast. 19, 1069–1095 (2003)

Kröner E.: Allgemeine Kontinuumstheorie der Versetzungen und Eigenspannungen. Arch. Ration. Mech. Anal. 4, 273–334 (1960)

Lee E.H.: Elastic plastic deformation at finite strain. ASME J. Appl. Mech. 36, 1–6 (1969)

Leonov A.I.: Nonequilibrium thermodynamics and rheology of viscoelastic polymer media. Rheol. Acta 15, 85–98 (1976)

Lion A.: On the large deformation behaviour of reinforced rubber at different temperatures. J. Mech. Phys. Solids 45, 1805–1834 (1997)

Lubarda V.A., Benson D.J., Meyers M.A.: Strain-rate effects in rheological models of inelastic response. Int. J. Plast. 19, 1097–1118 (2003)

Makradi A., Ahzi S., Gregory R.V., Edie D.D.: A two-phase self-consistent model for the deformation and phase transformation behavior of polymers above the glass transition temperature: application to PET. Int. J. Plast. 21, 741–750 (2005)

Mayo S.L., Olafson B.D., Goddard W.A. III: Dreiding: a generic force field for molecular simulations. J. Phys. Chem. 94, 8897–8909 (1990)

Miehe C., Goktepe S., Mendez Diez J.: Finite viscoplasticity of amorphous glassy polymers in the logarithmic strain space. Int. J. Solids Struct. 46, 181–202 (2008)

Nose S.: A molecular dynamics method for simulations in the canonical ensemble 1. Mol. Phys. 50, 255–268 (1984)

Ogden, R.W.: Large deformation isotropic elasticity—on the correlation of theory and experiment for incompressible rubberlike solids. In: Proceedings of the Royal Society of London, vol. A326, pp. 565–584 (1972)

Perzyna P.: Fundamental problems in viscoplasticity. Adv. Appl. Mech. 9, 243–377 (1966)

Plimpton S.J.: Fast parallel algorithms for short-range molecular dynamics. J. Comput. Phys. 117, 1–19 (1995)

Prantil V.C., Jenkins J.T., Dawson P.R.: An analysis of texture and plastic spin for planar polycrystals. J. Mech. Phys. Solids 41, 1357–1382 (1993)

Reese S., Govindjee S.: A theory of finite viscoelasticity and numerical aspects. Int. J. Solids Struct. 35, 3455–3482 (1998)

Richeton J., Ahzi S., Daridon L., Remond Y.: A formulation of the cooperative model for the yield stress of amorphous polymers for a wide range of strain rates and temperatures. Polymer 46, 6035–6043 (2006)

Richeton J., Ahzi S., Vecchio K.S., Jiang F.C., Makradi A.: Modeling and validation of the large deformation inelastic response of amorphous polymers over a wide range of temperatures and strain rates. Int. J. Solids Struct. 44, 7938–7954 (2007)

Rivlin R.S., Saunders D.W.: Large elastic deformations of isotropic materials VII. Experiments on the deformation of rubber. Philos. Trans. R. Soc. Lond. A 243, 251–2881 (1951)

Robbins M.O., Hoy R.S.: Scaling of the strain hardening modulus of glassy polymers with the flow stress. J. Polym. Sci. B 47, 1406 (2009)

Shepherd J.E., McDowell D.L., Jacob K.I.: Modeling morphology evolution and mechanical behavior during thermo-mechanical processing of semi-crystalline polymers. J. Mech. Phys. Solids 54, 467–489 (2006)

Shepherd, J.E.: Multiscale modeling of the deformation of semi-crystalline polymers. Ph. D. thesis, Georgia Institute of Technology, Atlanta, GA (2006)

Tomita Y.: Constitutive modeling of deformation behavior of glassy polymers and applications. Int. J. Mech. Sci. 42, 1455–1469 (2000)

Tervoort T.A., Smit R.J.M., Brekelmans W.A.M., Govaert L.E.: A constitutive equation for the elasto-viscoplastic deformation of glassy polymers. Mech. Time Depend. Mater. 1, 269–291 (1998)

Tervoort T.A., Govaert L.E.: Strain-hardening behavior of polycarbonate in the glassy state. J. Rheol. 44, 1263–1277 (2000)

Van der Sluis O., Schreurs P.J.G., Meijer H.E.H.: Homogenisation of structured elastoviscoplastic solids at finite strains. Mech. Mater. 33, 499–522 (2001)

Yeoh O.H.: Characterization of elastic properties of carbon-black-filled rubber vulcanizates. Rubber Chem. Technol. 63, 792–805 (1990)

Wendlandt M., Tervoort T.A., Suter U.W.: Nonlinear, rate dependent strain-hardening behavior of polymer glasses. Polymer 46, 11786–11797 (2005)

Wu P.D., Van der Giessen E.: On improved network models for rubber elasticity and their applications to orientation hardening in glassy polymers. J. Mech. Phys. Solids 41, 427–456 (1993)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bouvard, J.L., Ward, D.K., Hossain, D. et al. A general inelastic internal state variable model for amorphous glassy polymers. Acta Mech 213, 71–96 (2010). https://doi.org/10.1007/s00707-010-0349-y

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00707-010-0349-y