Abstract

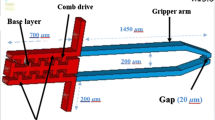

This paper reports a novel design for electrostatic microgrippers. The new structure utilizes rotary comb actuators to solve the pull-in problem of microgrippers during large displacement manipulation and therefore avoids the widely used conversion systems which necessitate a high driving voltage. The gripper is fabricated using a SOI process with a 60 μm structural layer. Test results show the gripper obtained a displacement of 94 μm with an applied voltage of 100 V. An animal hair is gripped to demonstrate the applicability of the gripper for micro object manipulations.

Similar content being viewed by others

References

Agnus J, Nectoux P, Chaillet N (2005) Overview of microgrippers and design of a micromanipulation station based on a MMOC microgripper. In: 2005 IEEE international symposium on computational intelligence in robotics and automation, Proceedings, pp 117–123

Bazaz SA, Khan F, Shakoor RI (2011) Design, simulation and testing of electrostatic SOI MUMPs based microgripper integrated with capacitive contact sensor. Sensor Actuat a-Phys 167(1):44–53. doi:10.1016/j.sna.2010.12.003

Beyeler F, Bell DJ, Nelson BJ, Sun Y, Neild A, Oberti S, Dual J (2006) Design of a micro-gripper and an ultrasonic manipulator for handling micron sized objects. In: 2006 IEEE/RSJ international conference on intelligent robots and systems, Vols 1–12, pp 772–777

Beyeler F, Neild A, Oberti S, Bell DJ, Sun Y, Dual J, Nelson BJ (2007) Monolithically fabricated microgripper with integrated force sensor for manipulating microobjects and biological cells aligned in an ultrasonic field. J Microelectromech Syst 16(1):7–15. doi:10.1109/Jmems.2006.885853

Chang H, Zhao H, Xie J, Hao Y, Zhang F, Yuan W(2012) Design and fabrication of a rotary comb-actuated microgripper with high driving efficiency. In: 2012 IEEE 25th international conference on micro electro mechanical systems (MEMS), Jan. 29 2012–Feb. 2 2012, pp 1145–1148. doi:10.1109/memsys.2012.6170365

Chen T, Chen LG, Sun LN, Li XX (2009) Design and Fabrication of a Four-Arm-Structure MEMS Gripper. IEEE Trans Industr Electron 56(4):996–1004. doi:10.1109/Tie.2008.2005147

Chen T, Sun LN, Chen LG, Rong WB, Li XX (2010) A hybrid-type electrostatically driven microgripper with an integrated vacuum tool. Sensor Actuat a-Phys 158(2):320–327. doi:10.1016/j.sna.2010.01.001

Dario P, Carrozza MC, Benvenuto A, Menciassi A (2000) Micro-systems in biomedical applications. J Micromech Microeng 10(2):235–244

Kim CJ, Pisano AP, Muller RS, Lim MG (1990) Polysilicon microgripper. In: solid-state sensor and actuator workshop. 4th Technical Digest., IEEE, 4–7 Jun 1990, pp 48–51. doi:10.1109/solsen.1990.109818

Okamura AM, Smaby N, Cutkosky MR (2000) An overview of dexterous manipulation. In: IEEE international conference on robotics and automation, Proceedings, ICRA ‘00, vol.251 pp 255–262. doi:10.1109/robot.2000.844067

Tu C-C, Fanchiang K, Liu CH (2005) 1 x N rotary vertical micromirror for optical switching applications. In: Ayman E-F (ed), SPIE, pp 14–22

Volland BE, Heerlein H, Rangelow IW (2002) Electrostatically driven microgripper. Microelectron Eng 61–2:1015–1023

Yeh JA, Chen CN, Liu YS (2005) Large rotation actuated by in-plane rotary comb-drives with serpentine spring suspension. J Micromech Microeng 15(1):201–206. doi:10.1088/0960-1317/15/1/028

Yeh JA, Huang JY, Chen CN, Hui CY (2006) Design of an electrostatic rotary comb actuator. J Microlith Microfab 5 (2). doi:10.1117/1.2198532

Acknowledgments

The authors would like to acknowledge the financial support from Chinese National Science Foundation (Grant Number: 60976087), Chinese New Century Excellent Talents in University (Grant number: NCET-10-0077), and the Programme of Introducing Talents of Discipline to Universities.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chang, H., Zhao, H., Ye, F. et al. A rotary comb-actuated microgripper with a large displacement range. Microsyst Technol 20, 119–126 (2014). https://doi.org/10.1007/s00542-013-1737-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00542-013-1737-8