Abstract

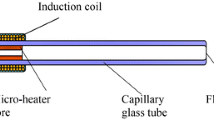

This paper presents a study of a new tubular vaporizing liquid micro-thruster (VLM) with induction heating. The developed micro-thruster consists of a micro-heater core, an excitation coil, a vaporizing chamber, a nozzle and a micro-channel, all integrated in a glass tube with a dimension of 3 mm (outer diameter) × 18 mm (length). The temperature of the micro-heater core is tested with experiments and an optimal AC frequency is selected for the VLM based on the experimental tests. Vaporization of water-propellant feeding with different flow rates range of 0.1 ml/min − 0.3 ml/min is demonstrated. A maximum thrust force of 680 μN at 0.3 ml/min propellant consumption rate is realized measured with a pendulum thrust stand. Comparing with other VLMs, one merit of the new VLM is that there is no physical connection between the micro-heater core and the power supply. Other merits of the new VLM proposed by this paper is that it can work with a larger input power, provide more heat energy and generate a relative larger thrust force.

Similar content being viewed by others

References

Barnhart DJ, Vladimirova T, Sweeting MN (2007) Very-small-satellite design for distributed space missions. J Spacecr Rocket 44(6):1294–1306

Bouwmeester J, Guo J (2010) Survey of worldwide pico- and nanosatellite missions, distributions and subsystem technology. Acta Astronaut 67(7–8):854–862

Böhrk H, Auweter-Kurtz M (2009) Thrust measurement of the hybrid electric thruster TIHTUS by a baffle plate. J Propuls Power 25(3):729–736

Cen JW, Xu JL (2010) Performance evaluation and flow visualization of a MEMS based vaporizing liquid micro-thruster. Acta Astronaut 67(3–4):468–482

Cheah KH, Low KS (2015) Fabrication and performance evaluation of a high temperature co-fired ceramic vaporizing liquid microthruster. J Micromech Microeng 25(1):015013

De Giorgi MG, Fontanarosa D (2019) A novel quasi-one-dimensional model for performance estimation of a vaporizing liquid microthruster. Aerosp Sci Technol 84:1020–1034

Dandavino S, Ataman C, Ryan CN, Chakraborty S, Courtney D, Stark JPW, Shea H (2014) Microfabricated electrospray emitter arrays with integrated extractor and accelerator electrodes for the propulsion of small spacecraft. J Micromech Microeng 24(7):075011

Deng P, Lee YK, Cheng P (2005) Measurements of micro bubble nucleation temperatures in DNA solutions. J Micromech Microeng 15(3):564–574

Gao Y, Ma YF, Liu JT (2014) A review of the vaporizing liquid microthruster technology. 2014 ISFMFE - 6th international symposium on fluid machinery and fluid engineering

Grubišić AN, Gabriel SB (2010) Development of an indirect counterbalanced pendulum optical-lever thrust balance for micro-to millinewton thrust measurement. Meas Sci Technol 21(10):105101

Karthikeyan K, Chou SK, Khoong LE, Tan YM, Lu CW, Yang WM (2012) Low temperature co-fired ceramic vaporizing liquid microthruster for microspacecraft applications. Appl Energy 97:577–583

Kundu P, Bhattacharyya TK, Das S (2012) Design, fabrication and performance evaluation of a vaporizing liquid microthruster. J Micromech Microeng 22(2):025016

Kundu P, Sinha AK, Bhattacharyya TK, Das S (2013) MnO2 nanowire embedded hydrogen peroxide monopropellant MEMS thruster. J Microelectromech Syst 22(2):406–417

Köhler J, Simu U, Bejhed J, Kratz H, Jonsson K, Nguyen H, Bruhn F, Hedlund C, Lindberg U, Hjort K, Stenmark L (2002) A hybrid cold gas microthruster system for spacecraft. Sensors Actuators A Phys 97(1):587–598

Lee J, Kim T (2013) MEMS solid propellant thruster array with micro membrane igniter. Sensors Actuators A Phys 190:52–60

Liu BD, Hou YP, Li DS, Yang JH (2015) A thermal bubble micro-actuator with induction heating. Sensors Actuators A Phys 222:8–14

Liu BD, Li XR, Yang JH, Gao GH (2019) Recent advances in MEMS-based microthrusters. Micromachines. 10(12):818

Li XC, Huang YY, Chen XQ, Xu XM, Xiao DB (2018) Electro-thermal analysis of an Al–Ti multilayer thin film microheater for MEMS thruster application. Microsyst Technol 24:2409–2417

Maurya DK, Das S, Lahiri SK (2005) An analytical model of a silicon MEMS vaporizing liquid microthruster and some experimental studies. Sensors Actuators A Phys 122(1):159–166

Mueller J, Tang W, Wallace A, Lawton R, Li W, Bame D, Bame D (1997) Design, analysis and fabrication of a vaporizing liquid micro-thruster. In 33rd joint propulsion conference and exhibit, AIAA

Mukerjee EV, Wallace AP, Yan KY, Howard DW, Smith RL, Collins SD (2000) Vaporizing liquid microthruster. Sensors Actuators A Phys 83(1–3):231–236

Patel KD, Bartsch MS, McCrink MH, Olsen JS, Mosier BP, Crocker RW (2008) Electrokinetic pumping of liquid propellants for small satellite microthruster applications. Sensors Actuators B Chem 132(2):461–470

Ranjan R, Karthikeyan K, Riaz F, Chou SK (2018) Cold gas propulsion microthruster for feed gas utilization in micro satellites. Appl Energy 220:921–933

Rossi C, Orieux S, Larangot B, Do Conto T, Esteve D (2002) Design, fabrication and modeling of solid propellant microrocket-application to micropropulsion. Sensors Actuators A Phys 99(1–2):125–133

Silva MA, Guerrieri DC, Van Zeijl H, Cervone A, Gill E (2017) Vaporizing liquid microthrusters with integrated heaters and temperature measurement. Sensors Actuators A Phys 265:261–274

Xiong J, Zhou Z, Sun D, Ye X (2005) Development of a MEMS based colloid thruster with sandwich structure. Sensors Actuators A Phys 117(1):168–172

Ye XY, Tang F, Ding HQ, Zhou ZY (2001) Study of a vaporizing water micro-thruster. Sensors Actuators A Phys 89(1–2):159–165

Acknowledgements

This work was financially supported by National Innovative Methodology Project of China (No. 2018IM0301004) and Natural Science Foundation of Beijing (No. 3192010).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interests

The authors declare that there is no conflict of interests regarding the publication of this paper.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Liu, B., Yang, X., Wang, Y. et al. A tubular vaporizing liquid micro-thruster with induction heating. Heat Mass Transfer 56, 2035–2043 (2020). https://doi.org/10.1007/s00231-020-02836-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-020-02836-7