Abstract

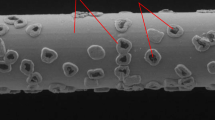

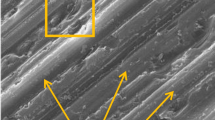

This paper presents a novel fixed and free abrasive combined wire sawing which uses the diamond wire with surface abrasive-groups interval distribution and combines with free SiC abrasives slurry to obtain sliced surface that can be textured by acid etching. During the sawing process, the ability that the free abrasives lapping the sawn surface has a positive correlation with the elasto-hydrodynamic (EHD) pressure, and the appropriate size of the free abrasives is related to the minimum film thickness of the cutting coolant. In this paper, the EHD action during the FFACWS is analyzed, and the film thickness equation and Reynolds equation of the sawing area are deduced. The influences of feed speed, wire speed, wire tensioning force, cutting coolant viscosity, core wire diameter, and surface structure parameters on EHD pressure and film thickness are analyzed, which provides theoretical reference for selection of the free abrasives diameter and analysis of their lapping effect on the slice surface. The research results show that the EHD pressure changes periodically in the direction of the wire axis in the entire sawing area. The change period is the same as a structural change period of the abrasive area (AA) and the bare wire area (BWA) on the wire surface. In one period, there are two EHD pressure peaks. The size range of free abrasives should be greater than the protruding height of the fixed abrasives on the diamond wire and less than the minimum film thickness in BWA, so that the free abrasives can be constrained in BWA to lap the slice surface.

Similar content being viewed by others

Data availability

All data generated or analyzed during this study are included in this published article.

References

Sansaniwal SK, Sharma V, Mathur J (2017) Energy and exergy analyses of various typical solar energy applications: a comprehensive review. Renew Sust Energ Rev 82(1):1576–1601

Li HS, Gao YF, Ge PQ, Bi WB, Zhang L (2020) Study on process parameters of fabrication fine diameter electroplated diamond wire for slicing crystalline silicon solar cell. Int J Adv Manuf Technol 106(7-8):3153–3175

Santhakumari M, Sagar N (2019) A review of the environmental factors degrading the performance of silicon wafer-based photovoltaic modules: failure detection methods and essential mitigation techniques. Renew Sust Energ Rev 110:83–100

Deng R, Chang NL, Ouyang Z, Chong CM (2019) A techno-economic review of silicon photovoltaic module recycling. Renew Sust Energ Rev 109:532–550

Wang LY, Gao YF, Li XY, Pu TZ, Yin YK (2020) Analytical prediction of subsurface microcrack damage depth in diamond wire sawing silicon crystal. Mater Sci Semicond Process 112:105015

Yang F, Kao I (2001) Free abrasive machining in slicing brittle materials with wiresaw. J Electron Packag 123(3):254–259

Nievendick J, Specht J, Zimmer M, Zahner L, Glover W, Stüwe D, Rentsch G (2011) Formation of a honeycomb texture for multicrystalline silicon solar cells using an inkjetted mask. Phys Status Solidi-Res 6(1):7–9

Meinel B, Koschwitz T, Acker J (2012) Textural development of SiC and diamond wire sawed Sc-Silicon Wafer. Energy Procedia 27:330–336

Gopala Krishna Murthy HS (2015) Evolution and present status of silicon carbide slurry recovery in silicon wire sawing. Resour Conserv Recycl 104:194–205

Meißner D, Schoenfelder S, Hurka B, Zeh J, Sunder K, Koepge R, Wagner T, Grün A, Hagel HJ, Moeller HJ, Schwabe H, Anspach (2014) Loss of wire tension in the wire web during the slurry based multi wire sawing process. Sol Energ Mat Sol Cells 120:346–355

Li XY, Gao YF, Ge PQ, Zhang L, Bi WB (2019) The effect of cut depth and distribution for abrasives on wafer surface morphology in diamond wire sawing of PV polysilicon. Mater Sci Semicond Process 91:316–326

Yin YK, Gao YF, Li XY, Pu TZ, Wang LY (2020) Experimental study on slicing photovoltaic polysilicon with diamond wire saw. Mat Sci Semicon Peoc 106:104779

Meinel B, Koschwitz T, Blocks C, Acker J (2014) Comparison of diamond wire cut and silicon carbide slurry processed silicon wafer surfaces after acidic texturisation. Mat Sci Semicon Peoc 26:93–100

Pu TZ, Gao YF, Wang LY, Yin YK (2020) Experimental investigation on the machining characteristics of fixed-free abrasive combined wire sawing PV polysilicon solar cell. Int J Adv Manuf Technol 107(1-2):843–858

Bhagavat M, Prasad V, Kao I (2000) Elasto-hydrodynamic interaction in the free abrasive wafer slicing using a wiresaw: modeling and finite element analysis. J Tribol-T ASME 122(2):394–404

Gao YF, Ge PQ, Zhang L, Bi WB (2019) Material removal and surface generation mechanisms in diamond wire sawing of silicon crystal. Mat Sci Semicon Proc 103:104642

Ge PQ, Sang B, Gao YF (2008) The numerical analysis on action mechanism of slurry in free abrasive wiresaw slicing. Key Eng Mater 359-360:455–459

Liedke T, Kuna M (2011) A macroscopic mechanical model of the wire sawing process. Int J Mach Tool Manu 51(9):711–720

Christensen H (1969) Stochastic models for hydrodynamic lubrication of rough surfaces. P I Mech Eng 184:1013–1026

Code availability

Not applicable.

Funding

The work is financially supported by the National Natural Science Foundation of China (No.51875322), Natural Science Foundation of Shandong Province, China (No.ZR2019MEE012), and Project for Scientific Research Innovation Team of Young Scholar in Colleges and Universities of Shandong Province (2020KJB001).

Author information

Authors and Affiliations

Contributions

All authors participated in the work of the paper. Tianzhao Pu: methodology, writing—original draft preparation, data curation, formal analysis, visualization; Yufei Gao: conceptualization, methodology, writing - review and editing, project administration, funding acquisition, supervision; Youkang Yin: writing - review and editing; Liyuan Wang: validation. All authors have read and agreed to the published version of the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Pu, T., Gao, Y., Yin, Y. et al. Hydrodynamic action in slicing PV polysilicon with a novel fixed and free abrasive combined wire sawing. Int J Adv Manuf Technol 114, 509–523 (2021). https://doi.org/10.1007/s00170-021-06895-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-021-06895-w