Abstract

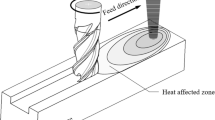

“Concept feasibility” has been shown for laser-assisted machining (LAM) using a 15 kW continuous-wave laser— the concept being that a laser beam will selectively heat the workpiece in a machining operation, and will thereby enable higher rates of metal removal to be achieved without a corresponding loss in tool life. The concept feasibility study involved two aerospace materials: Inconel 718 and Ti-6Al-4V. Ceramic tools were used for Inconel 718 and carbides for the titanium alloy. For both materials, the metal removal rate was significantly increased without aggravating either cutting force or tool wear, the gain in removal rate being 33 pct for Inconel 718 and 100 pct for Ti-6Al-4V using current tool materials and beam coupling techniques. The commercial feasibility of LAM requires (a) incorporation of the process into a “laser integrated manufacturing system,” or (b) dropping the power requirement to approximately 5 kW through improved beam coupling techniques, both of which serve to reduce the effective capital investment and operating costs for LAM. Application of LAM is foreseen for difficult-to-machine materials in parts for which the machining time is a major portion of the total floor-to-floor time and thus warrants minimizing.

Similar content being viewed by others

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Rajagopal, S., Plankenhorn, D.J. & Hill, V.L. Machining aerospace alloys with the aid of a 15 kW laser. J. Applied Metalworking 2, 170–184 (1982). https://doi.org/10.1007/BF02834035

Issue Date:

DOI: https://doi.org/10.1007/BF02834035