Abstract

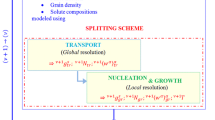

During alloy solidification, macrosegregation results from long range transport of solute under the influence of convective flow and leads to nonuniform quality of a solidified material. The present study is an attempt to understand the role of double diffusive convection resulting from the solutal rejection in the evolution of macrosegregation in an iron carbon system. The solifification process of an alloy is governed by conservation of heat, mass, momentum, and species and is accompanied by the evolution of latent heat and the rejection or incorporation of solute at the solid liquid interface. Using a continuum formulation, the goverming equations were solved using the finite volume method. The numerical model was validated by simulating experiments on an ammonium chloride water system reported in the literature. The model was further used to study the role of double diffusive convection in the evolution of macrosegregation during solidification of Fe 1 wt pct C alloy in a rectangular cavity. Simulation of this transient process was carried out until complete solidification, and the results, depicting the influence of flow field on thermal and solutal field andvice versa, are shown at various stages of solidification. Under the given set of parameters, it was found that the thermal buoyancy affects the macrosegregation field globally, whereas the solutal buoyancy has a localized effect.

Similar content being viewed by others

References

M.C. Flemings:Solification Processing, McGraw-Hill, New York, NY, 1974.

M.C. Flemings and G.E. Nereo:Trans. TMS AIME, 1967, vol. 239, pp. 1039–53.

R. Mehrabian, M. Keane, and M.C. Flemings:Metall. Trans., 1970, vol. 1, pp. 1209–20.

S.R. Coriell, M.R. Cordes, W.J. Boettinger, and R.F. Sekerka:J. Cryst. Growth, 1980, vol. 49, pp. 13–28.

G.B. McFadden, R.G. Rehm, S.R. Coriell, W. Chuck, and K.A. Morrish:Metall. Trans. A, 1984, vol. 15A, pp. 2125–37.

W.D. Bennon and F.P. Incropera:Int. J. Heat Mass Transfer, 1987, vol. 30, pp. 2161–70.

W.D. Bennon and F.P. Incropera:Int. J. Heat Mass Transfer, 1987, vol. 30, pp. 2171–87.

C. Beckermann and R. Viskanta:Phys. Chem. Hydrodyn., 1988, vol. 10, pp. 195–213.

V.R. Voller, A.D. Brent, and C. Prakash:Int. J. Heat Mass Transfer, 1989, vol. 32, pp. 1719–31.

D.G. Neilson and F.P. Incropera:Num. Heat Transfer A, 1993, vol. 23, pp. 1–20.

S.D. Felliceli, J.C. Heinrich, and D.R. Poirier:Num. Heat Transfer B, 1993, vol. 23, pp. 461–81.

Q.Z. Diao and H.L. Tsai:Metall. Trans. A, 1993, vol. 24A, pp. 963–73.

G. Amberg:Int. J. Heat Mass Transfer, 1991, vol. 34, pp. 217–27.

F. Roch, H. Combeau, J. Chevrier, and G. Lesoult: inModelling of Casting, Welding and Advanced Solidification Process-V, M. Rappaz, M.R. Ozgu, and K.W. Mahin, eds., TMS, Warrendale, PA, 1991, pp. 789–95.

A. Ghosh:Principles of Secondary Steel Processing and Casting of Liquid Steel, Oxford and IBH Publishing Co, New Delhi, 1990, pp. 129–32.

A.K. Singh and B. Basu:Proc. Int. Conf. on Advances in Physical Metallurgy, Mar. 1994, Bombay, India, Gordon and Breach Science Publishers, New York, NY, in press.

V.R. Voller and C. Prakash:Int. J. Heat Mass Transfer, 1987, vol. 30, pp. 1709–19.

G.K. Sigworth and C. Wang:Metall. Trans. B, 1993, vol. 24B, pp. 349–64.

R. West:Metall Trans. A, 1985, vol. 16A, p. 693–703.

V. Voller:Modelling Solidification Processes Mathematical Modelling of Materials Processing Operations, TMS, Warrendale, PA, 1987, pp. 987–1001.

S.V. Patankar:Numerical Heat Transfer and Fluid Flow, Hemisphere, New York, NY, 1980.

W.J. Minkowicz, E.M. Sparrow, G.E. Schneider, and R.H. Pletcher:Handbook of Numerical Heat Transfer, John Wiley and Sons Inc., New York, NY, 1988.

C.R. Swaminathan and V.R. Voller:Material Processing in Computer Age, TMS, Warrendale, PA, 1991, pp. 259–71.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Singh, A.K., Basu, B. Mathematical modeling of macrosegregation of iron carbon binary alloy: Role of double diffusive convection. Metall Mater Trans B 26, 1069–1081 (1995). https://doi.org/10.1007/BF02654109

Issue Date:

DOI: https://doi.org/10.1007/BF02654109